Sewing equipment head

A machine head and equipment technology, which is applied to sewing machine components, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of material deviation and poor positioning of the machine head, and achieve the effect of good sewing effect and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

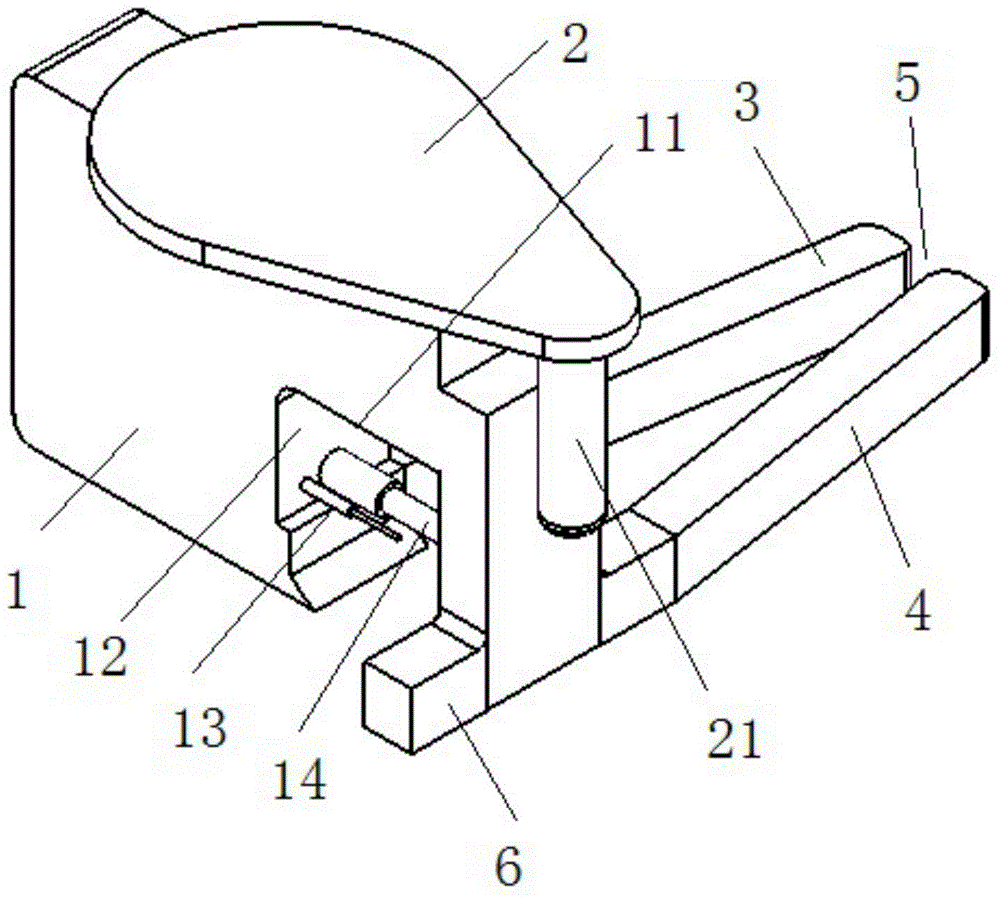

[0008] Please refer to the attached figure 1 , a sewing equipment head, comprising a plate-shaped base 1, the base 1 is vertically arranged, the top of the base 1 is provided with a cover plate 2, the shape of the cover plate 2 is drop-shaped, and the cover The bottom of the plate 2 is provided with a positioning pin 21 extending downwards, the positioning pin 21 is perpendicular to the cover plate 2, and it is used to position the machine head and other parts of the sewing equipment to prevent the machine head from shaking. The base 1 is provided with a through working cavity 11 along its thickness direction, the inner wall 12 of the working cavity 11 is provided with a positioning roller 13 and a needle 14, and the positioning roller 13 and the needle 14 are all perpendicular to the inner wall 12 , the base 1 is provided with a first positioning rod 3 and a second positioning rod 4 for positioning materials, a feed channel 5 is formed between the first positioning rod 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com