Method for controlling electronic pattern sewing machine to carry out herringbone sewing

A technology to control electronics and herringbone sewing, which is applied in sewing equipment, textiles and papermaking, etc., and can solve problems that affect the service life of the pattern machine, large vibration of the pattern machine, distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Describe the present invention below in conjunction with specific embodiment:

[0052] A method for controlling an electronic pattern machine to perform herringbone sewing in this embodiment includes the following steps:

[0053] Step 1: Create a herringbone pattern data file: the herringbone pattern data file includes a header file, key point data and pattern data;

[0054] The pattern data is generated through the following steps:

[0055] Step 1.1: Divide the pattern into a number of basic geometric figures that are connected in sequence. The basic geometric figures include straight lines, arcs, circles and free curves. The data is key point data;

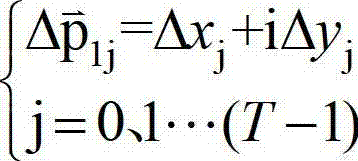

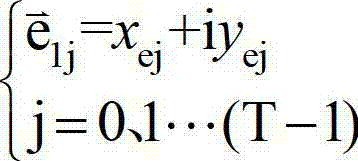

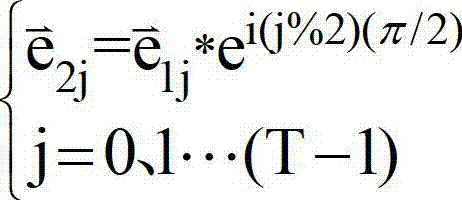

[0056] Step 1.2: Discretize the basic geometric figure with 1 / 2 of the feeding amount of the herringbone sewing as the stitch distance, and obtain the basic pattern data, expressed as follows in vector:

[0057] Δ p → ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com