Method for controlling electronic pattern making machine for realizing uniform discretization of patterns

A control method and discretization technology, applied to program-controlled sewing machines, textiles, papermaking, sewing equipment, etc., can solve problems such as unstable operation of electronic pattern machines and pattern distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Describe the present invention below in conjunction with specific embodiment:

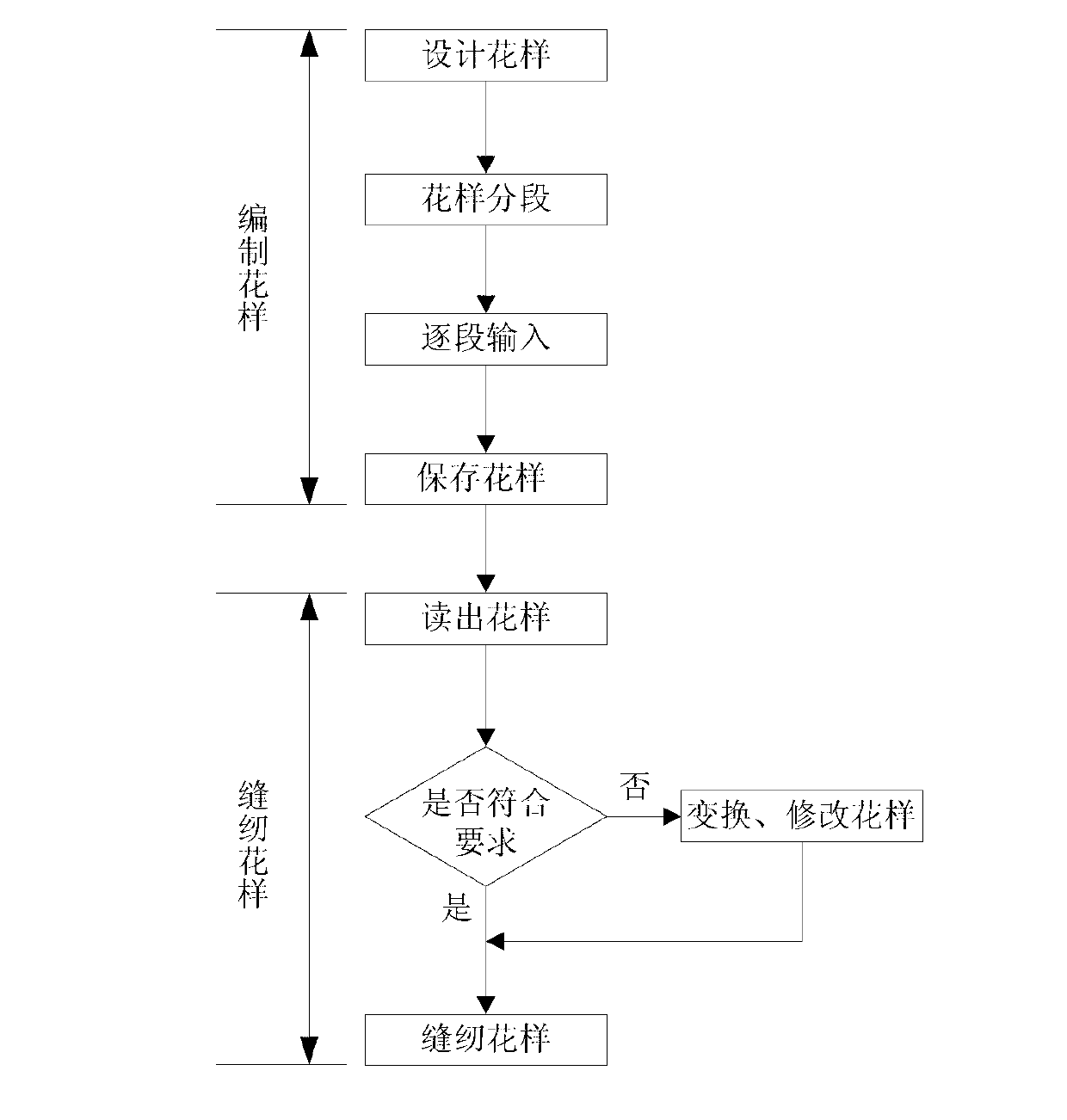

[0057] A control method of an electronic pattern machine for realizing uniform discretization of patterns in this embodiment includes the following steps:

[0058] Step 1: Create a pattern data file: the pattern data file includes a header file, key point data and pattern data;

[0059]The pattern data is generated through the following steps:

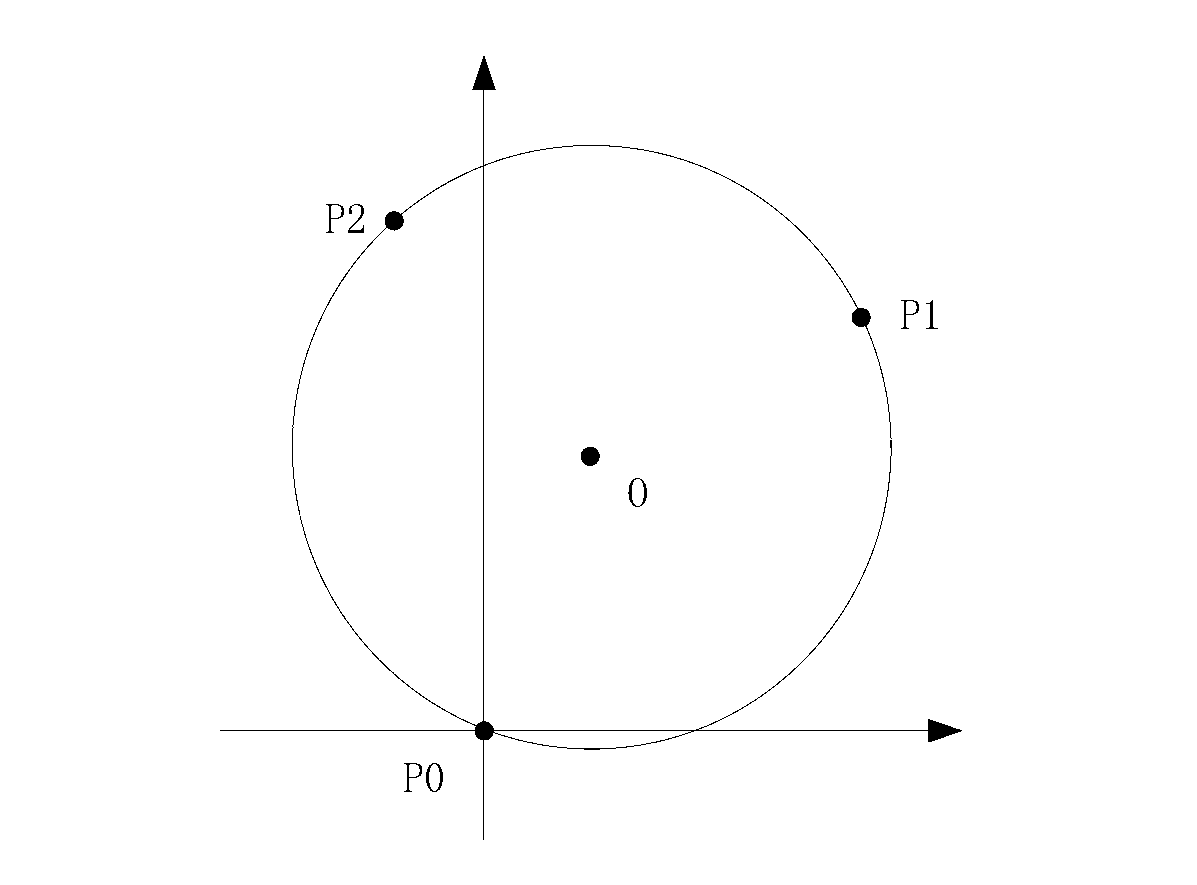

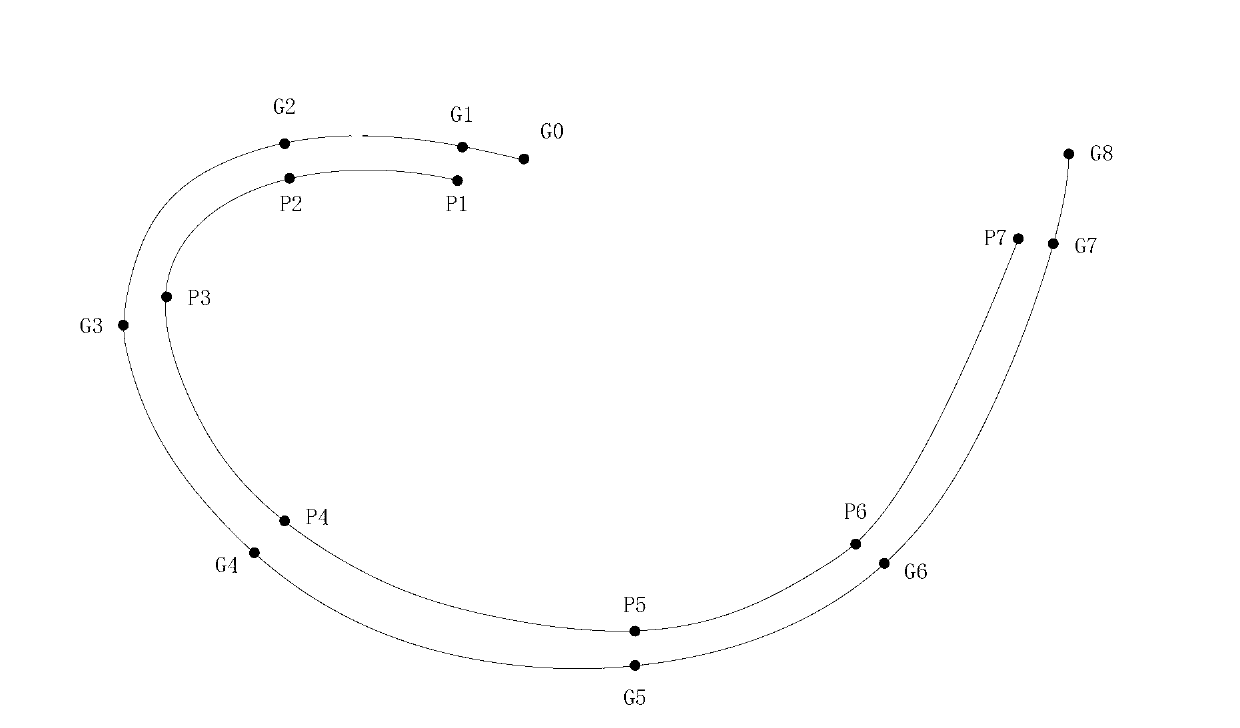

[0060] Step 1.1: According to the sewing process, the pattern is divided into several basic geometric figures that are connected in sequence. The basic geometric figures include straight line segments, circular arcs, circles and free curves. The data of points are key point data;

[0061] Step 1.2: Uniformly discretize each segment of the basic geometry according to the following method:

[0062] A: Uniform discretization of straight line segments:

[0063] Step A.1: Set the two points of the given line segment as O(0,0) and P(x,y), and the stitc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com