Patents

Literature

98results about How to "Realize automatic shutdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

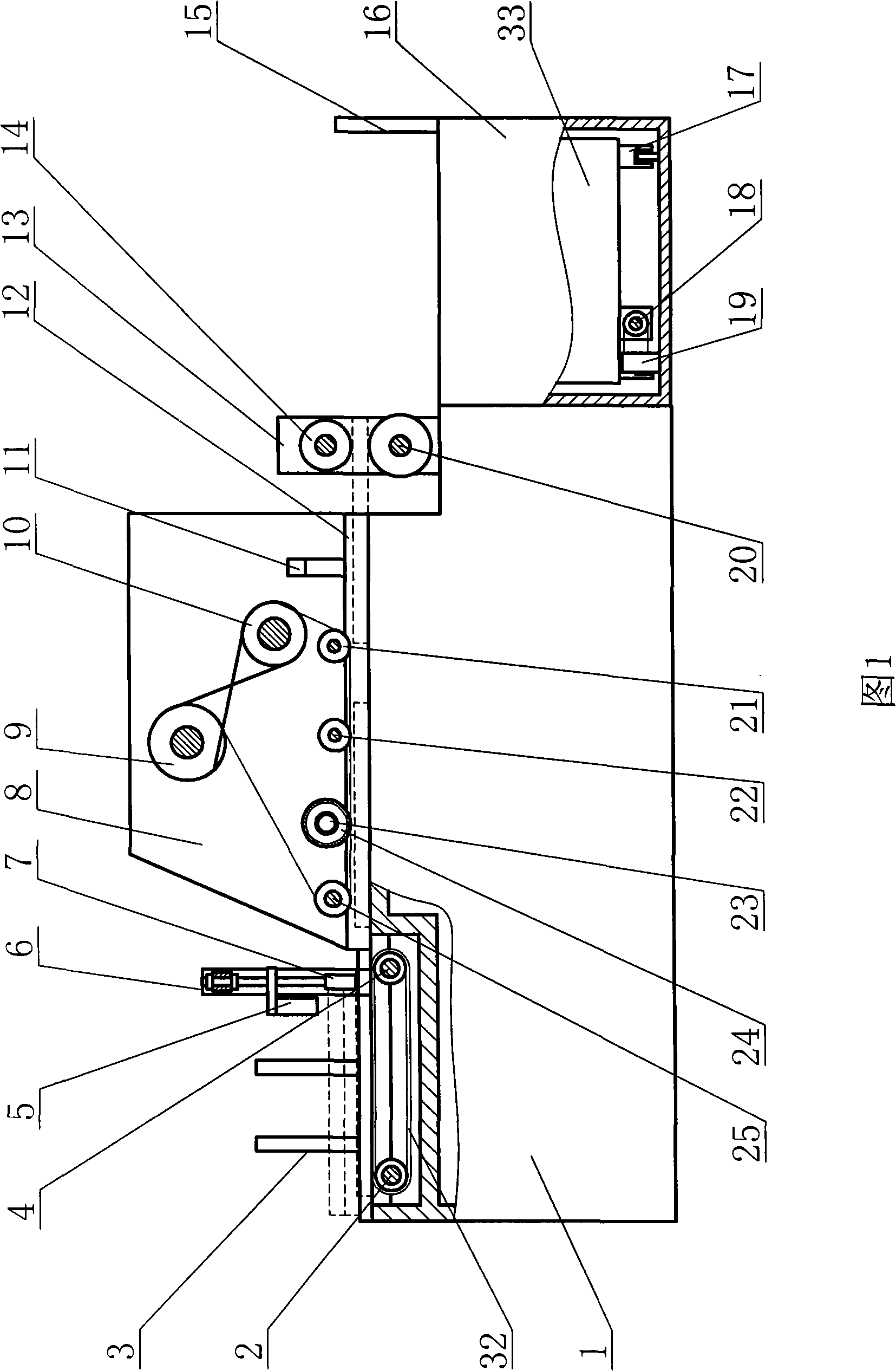

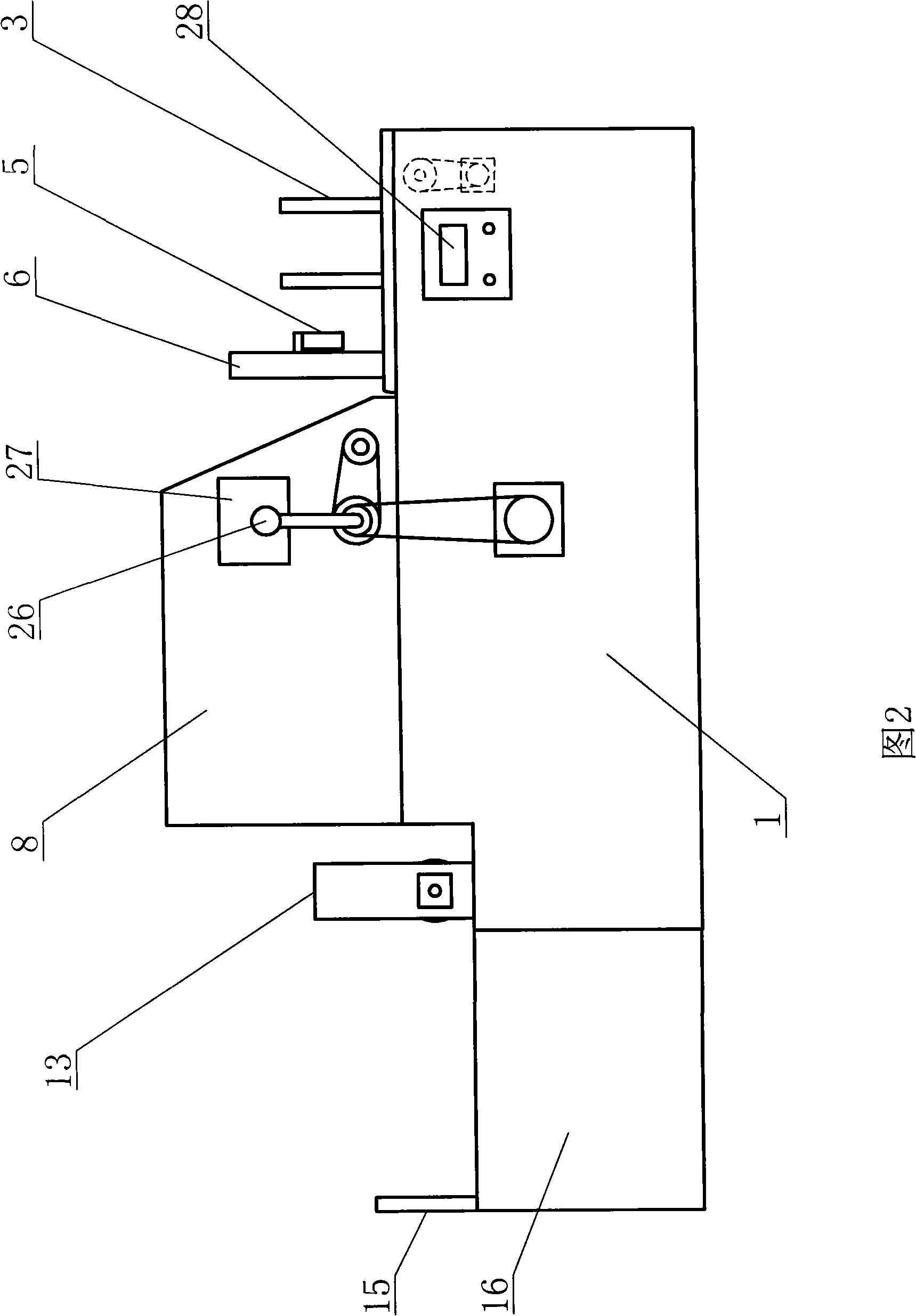

Oil-pressure chain rivet head machine

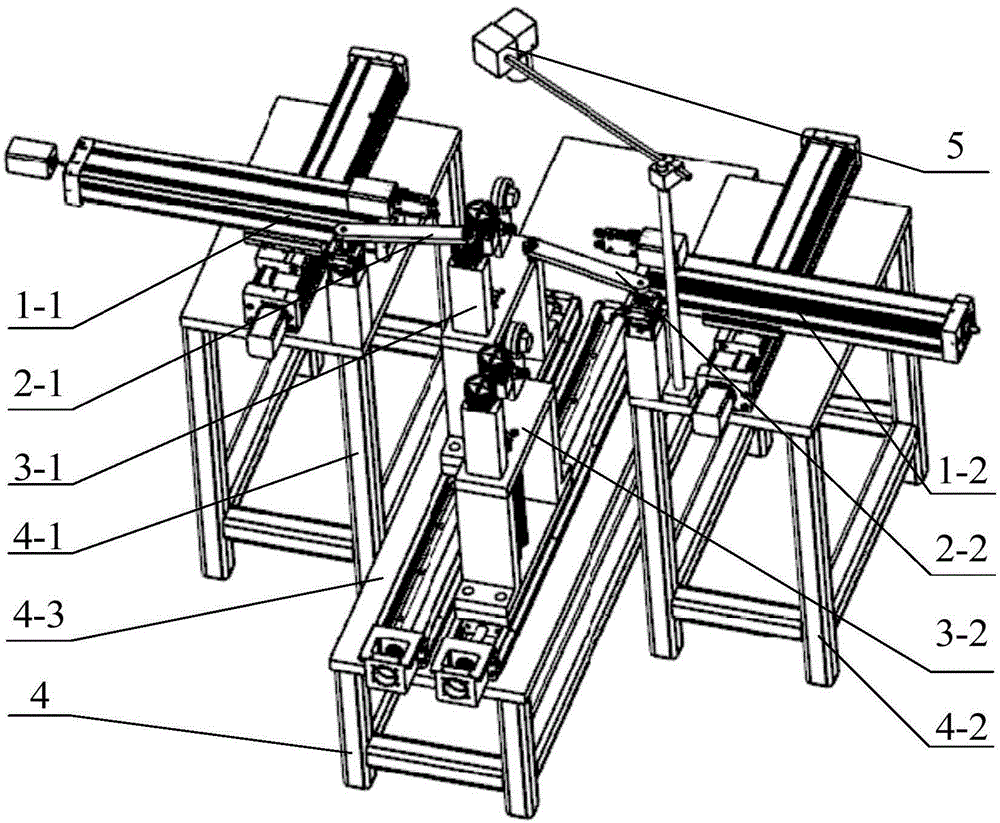

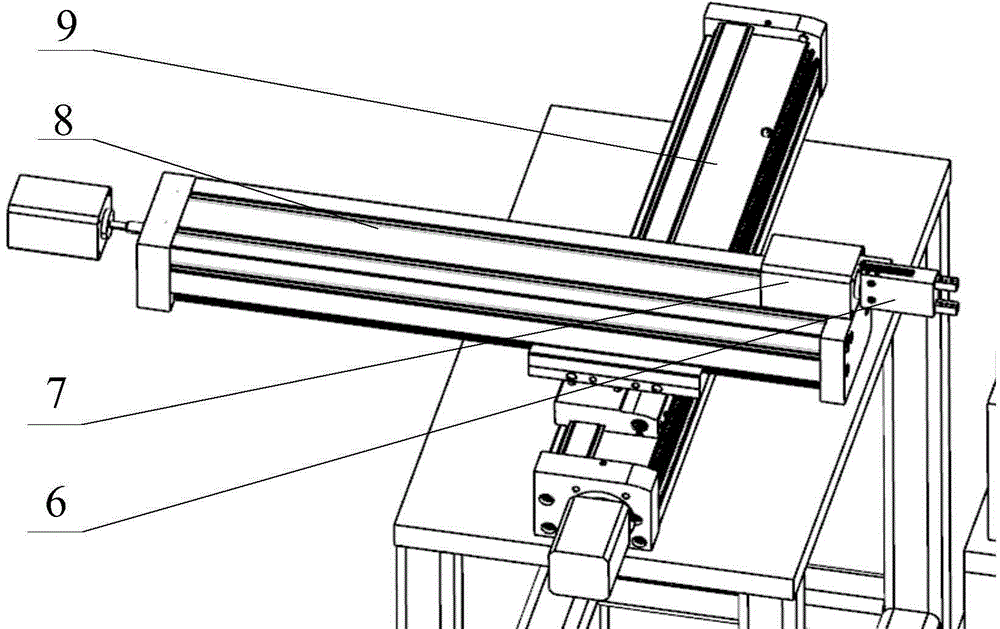

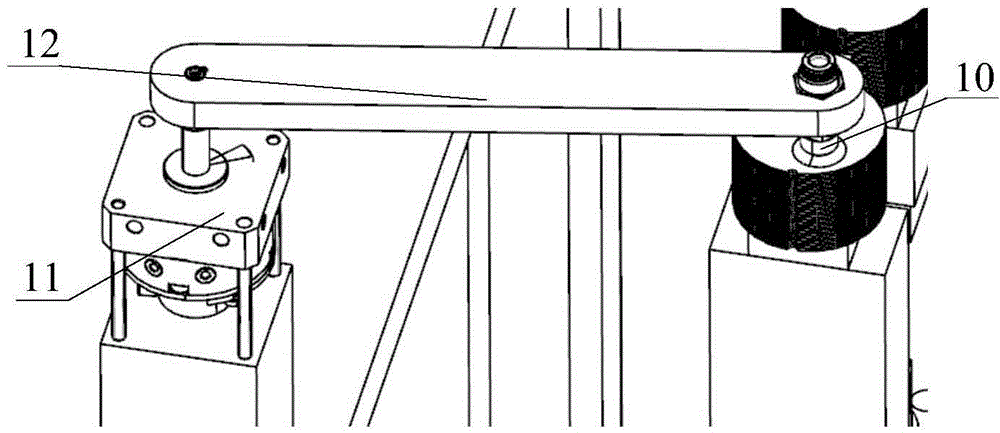

ActiveCN102861863AFlexible adjustmentEasy to detect and cut offMetal chainsHydraulic cylinderProgrammable logic controller

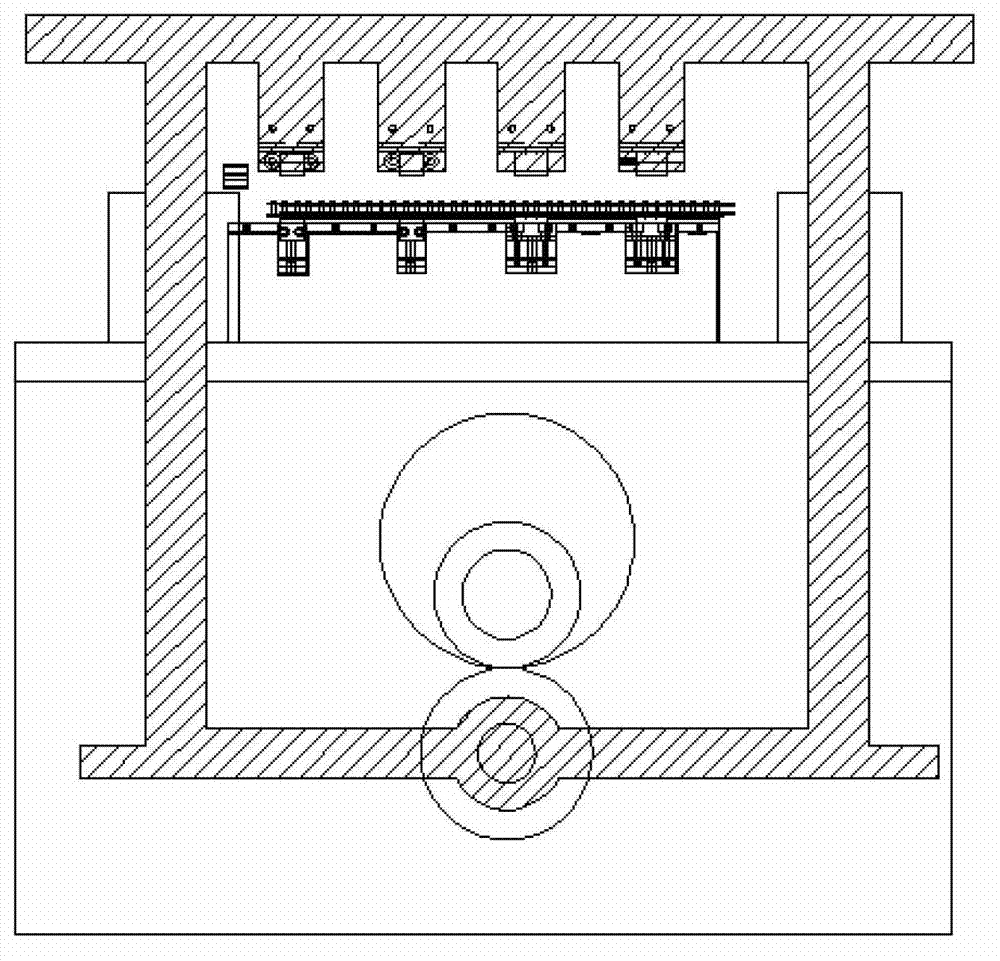

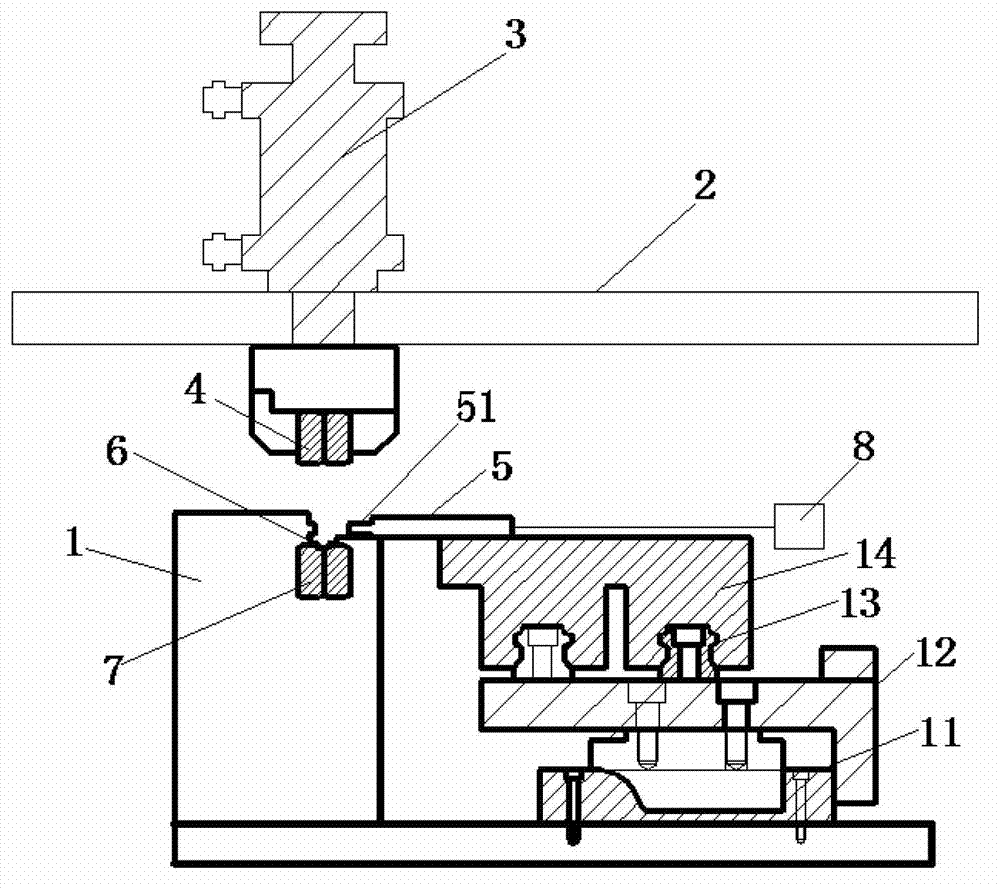

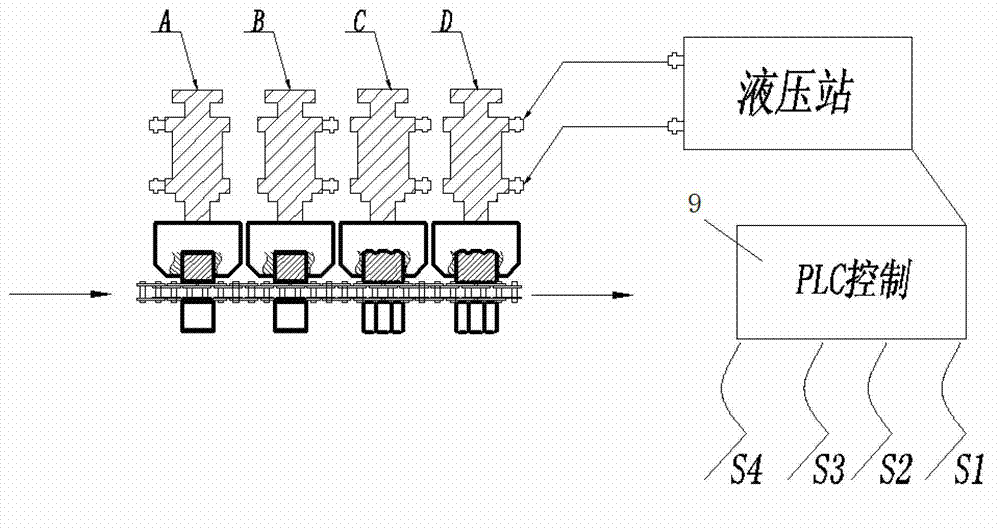

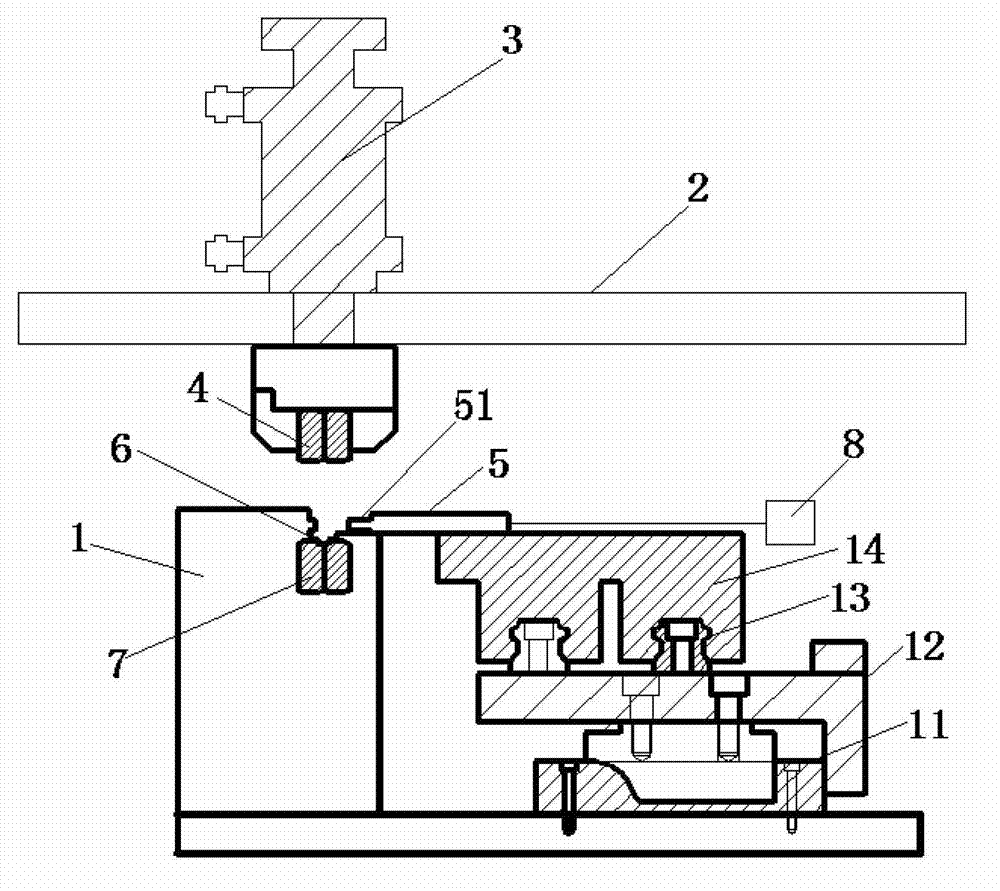

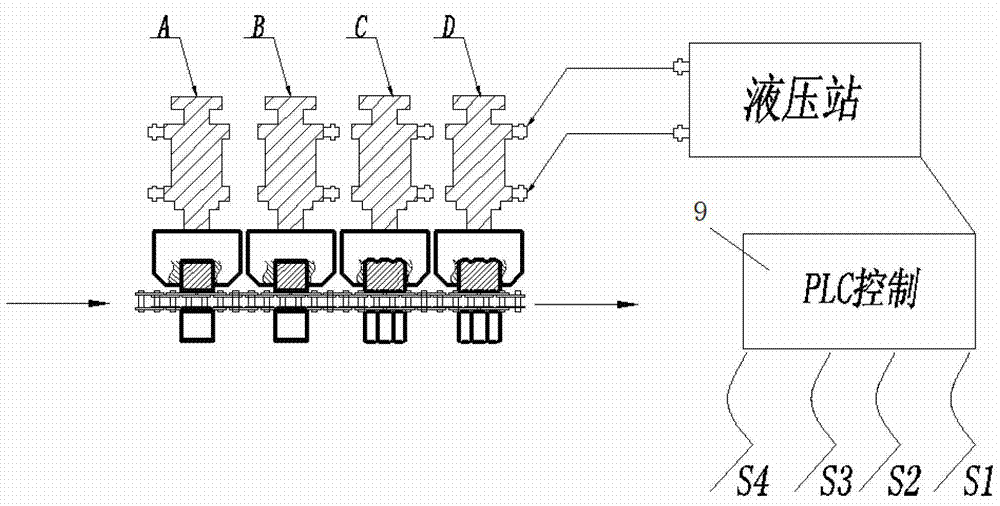

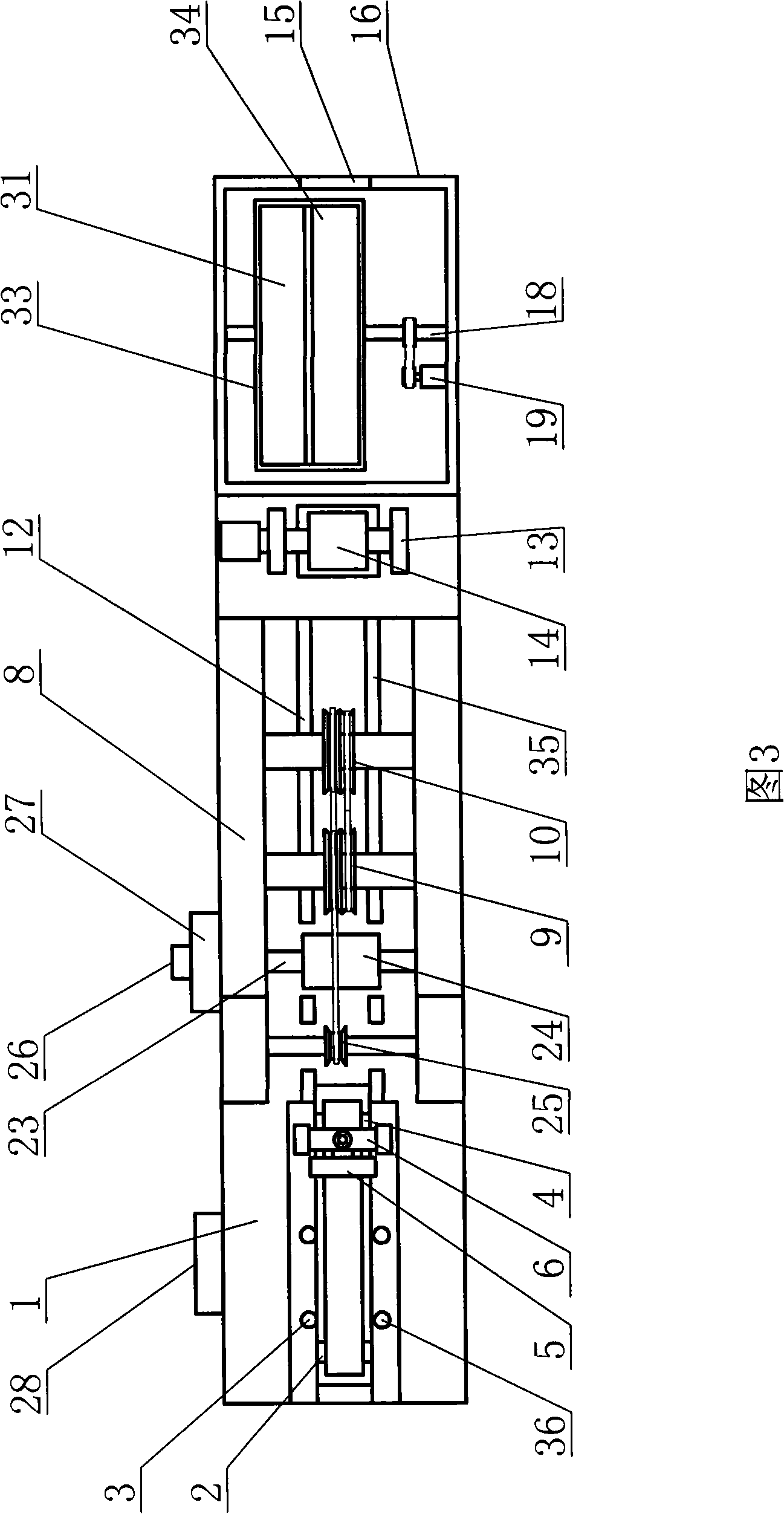

The invention provides an oil-pressure chain rivet head machine, comprising a worktable and a supporting frame, wherein the supporting frame is provided with a hydraulic cylinder and an upper rivet head die is connected below the hydraulic cylinder; a chain channel is arranged on the worktable; the chain channel is internally provided with a lower rivet head die at a position corresponding to the upper rivet head die; the worktable is further provided with a movable plate; and one side of the movable plate, which is close to the chain channel, is in a saw-tooth structure, and the movable plate is connected with a movable plate driving device. A PLC (Programmable Logic Controller) control device is combined with an oil-pressure system so as to realize full-automatic, intelligent and multifunctional rivet heads which can be a four-faced rivet head and a double-faced rivet head; and a certain section of a whole chain is not subjected to the rivet head so as to be convenient for post-period detection and cutting.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

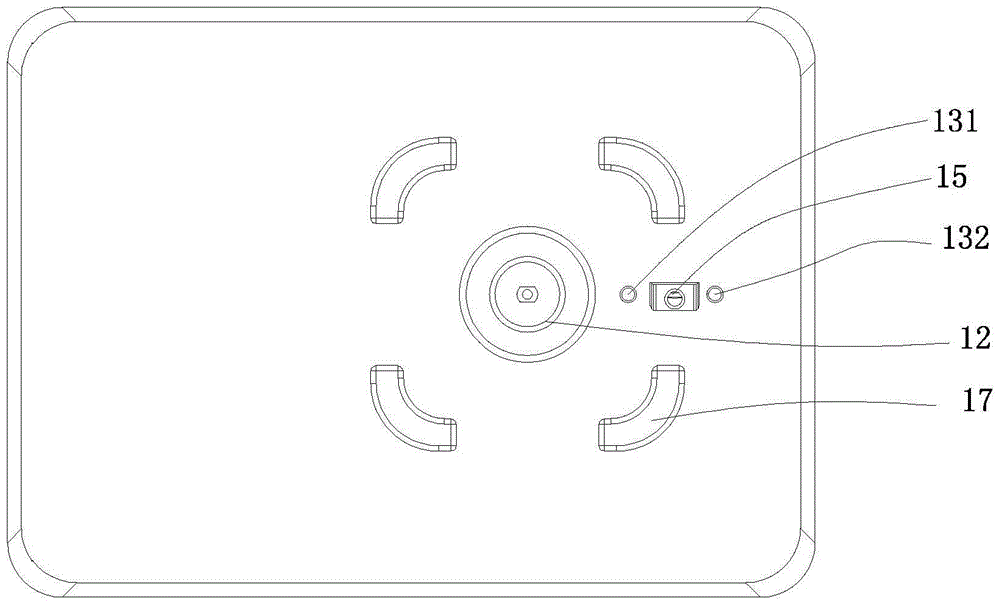

Multifunctional food processing platform

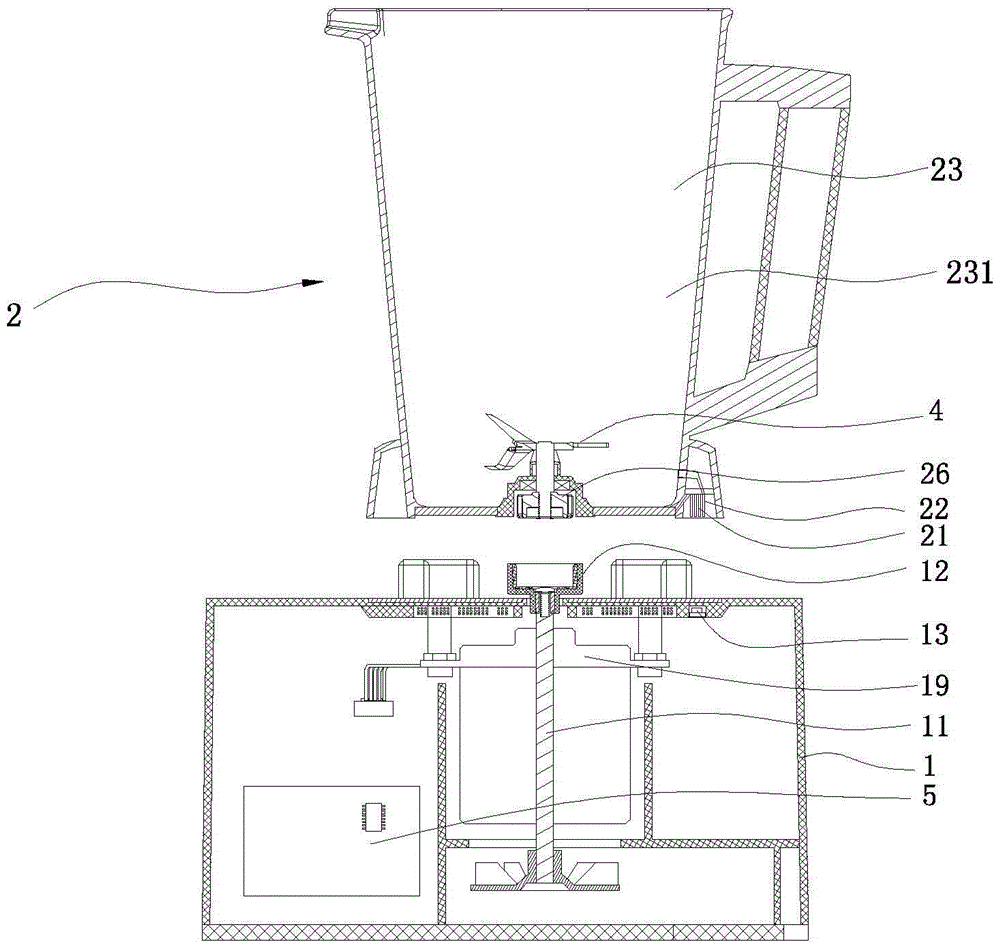

The invention relates to the technical field of domestic kitchen appliances, in particular to a multifunctional food processing platform. The multifunctional food processing platform comprises a machine base. A driving motor is arranged in the machine base. A speed feedback device is arranged on the driving motor. Matched food processing assemblies are arranged on the platform body. A plurality of sensors used for detecting whether the food processing assemblies are mounted in place or not are arranged on the machine base. A trigger mechanism is arranged at the bottoms of the food processing assemblies and corresponds to the sensors. The sensors are triggered by the trigger mechanism to identify the types of the processing assemblies. According to the types of the food processing assemblies, a control system controls the driving motor to act through the sensors, so that the food processing assemblies are driven to work correspondingly. Multiple functions of the platform are achieved, and the platform is more intelligent, automatic and humanized to use and can achieve the effect that foods manufactured through all functions are good in effect.

Owner:JOYOUNG CO LTD

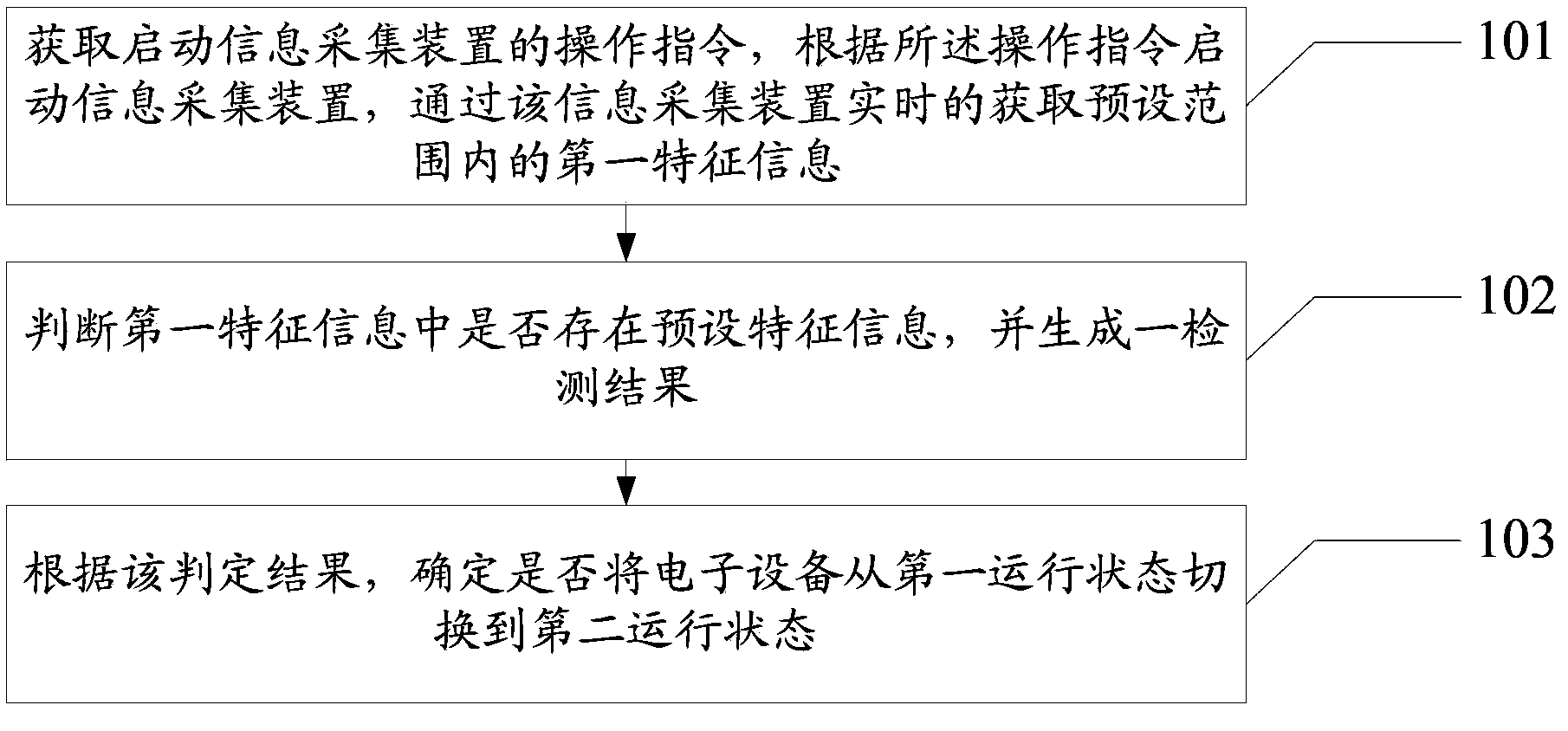

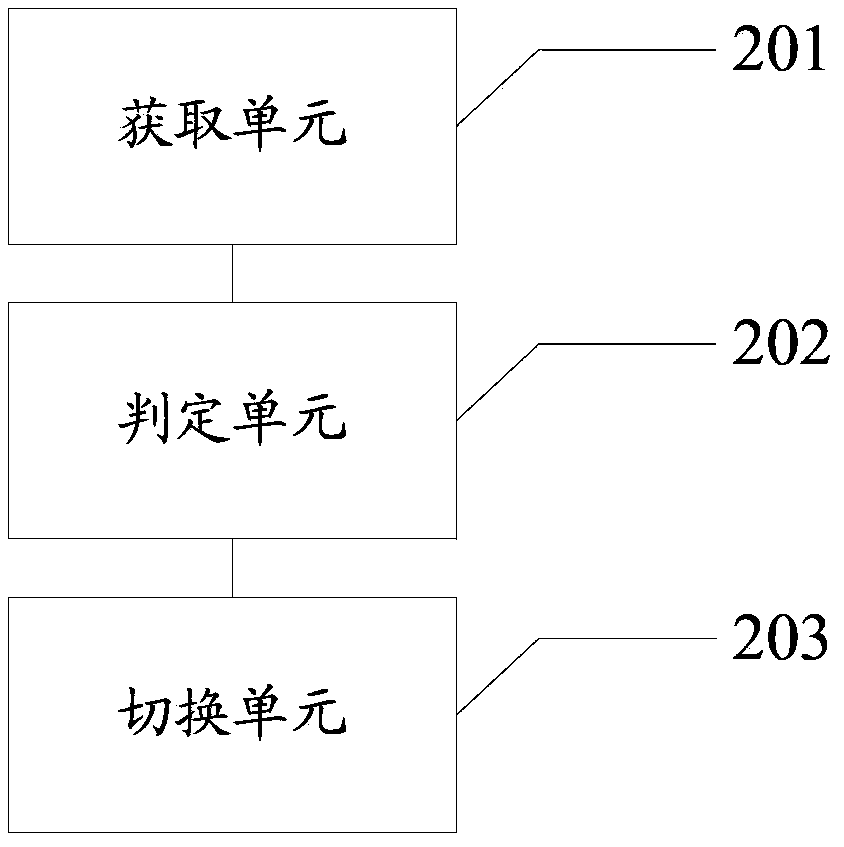

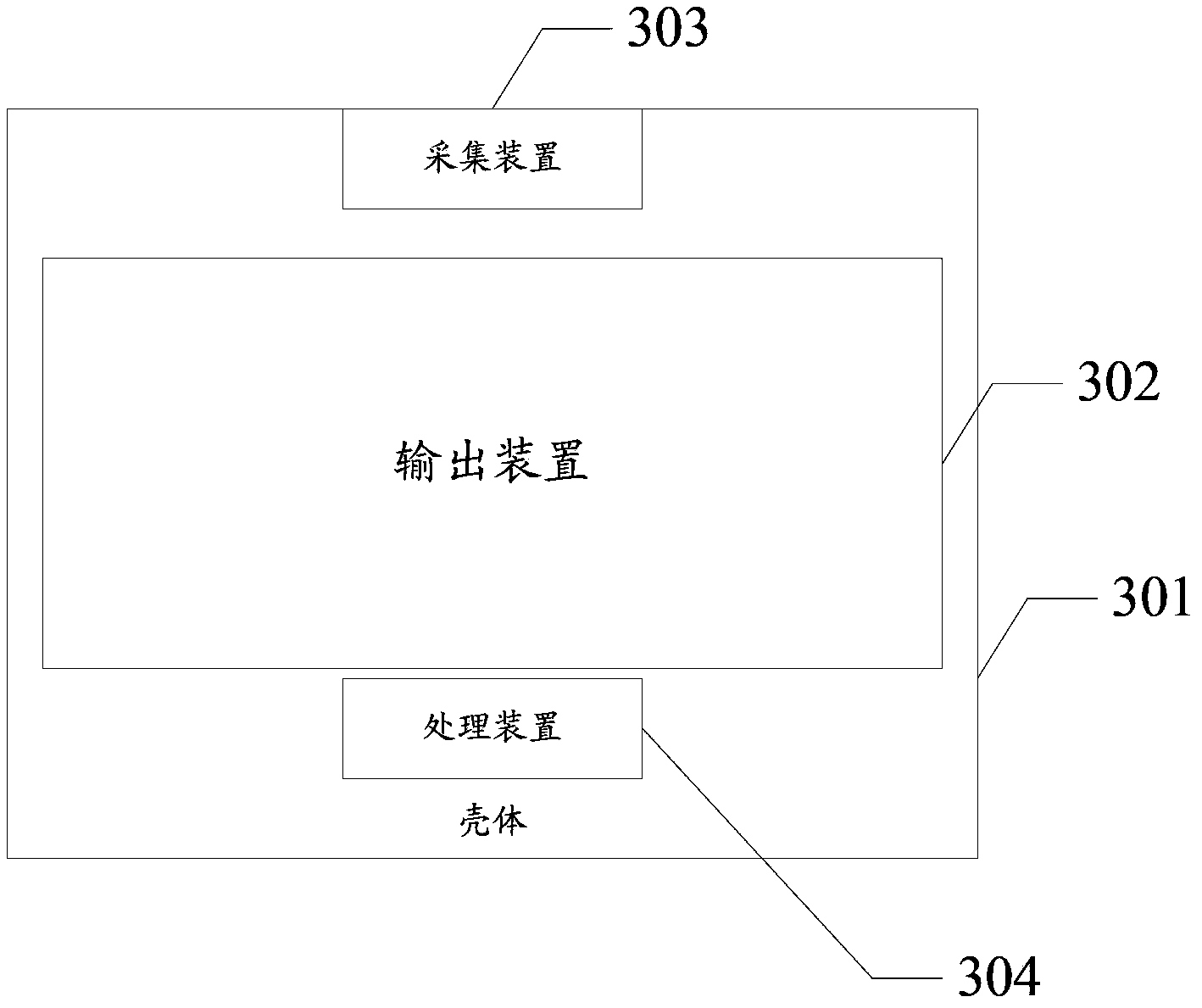

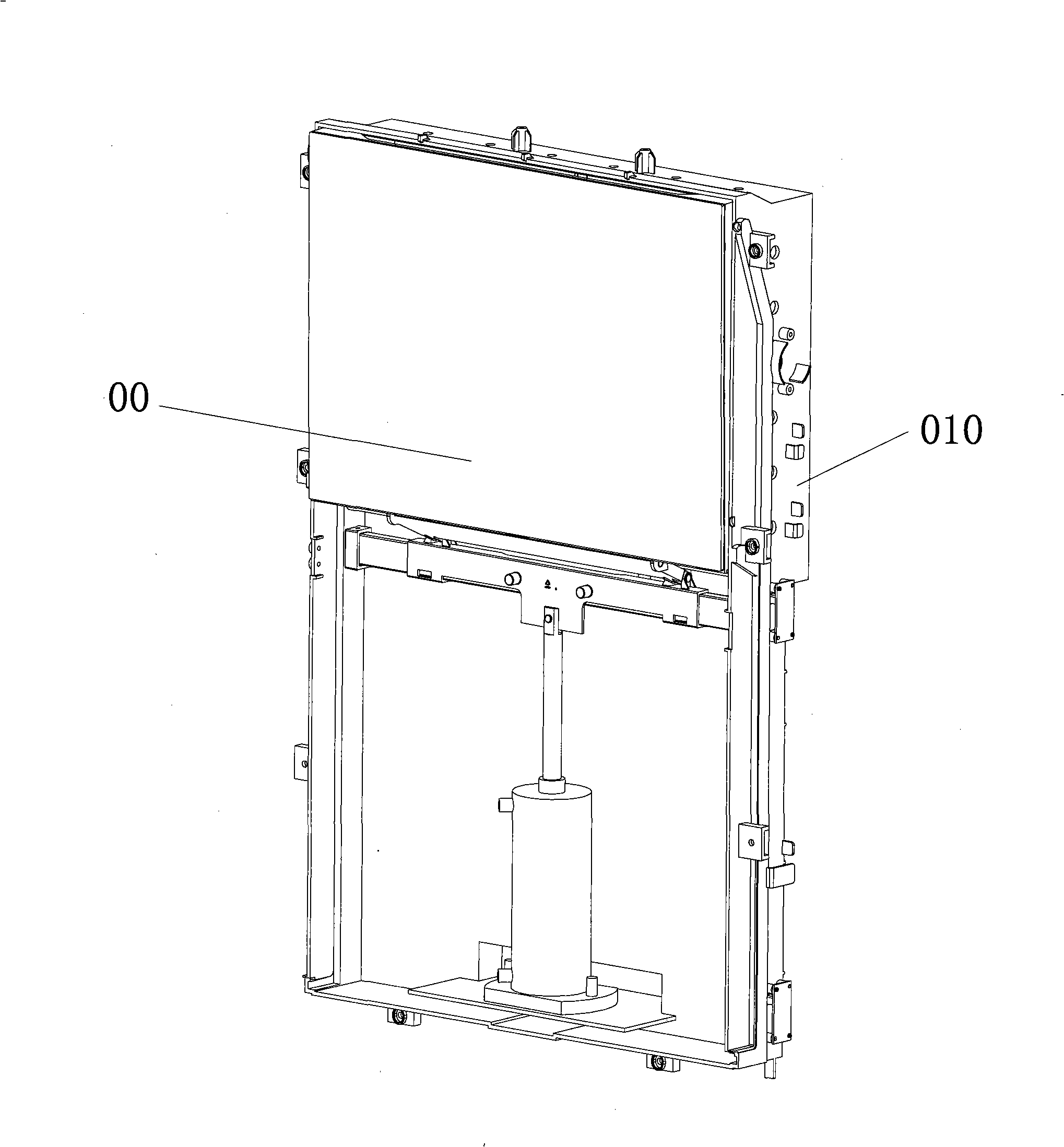

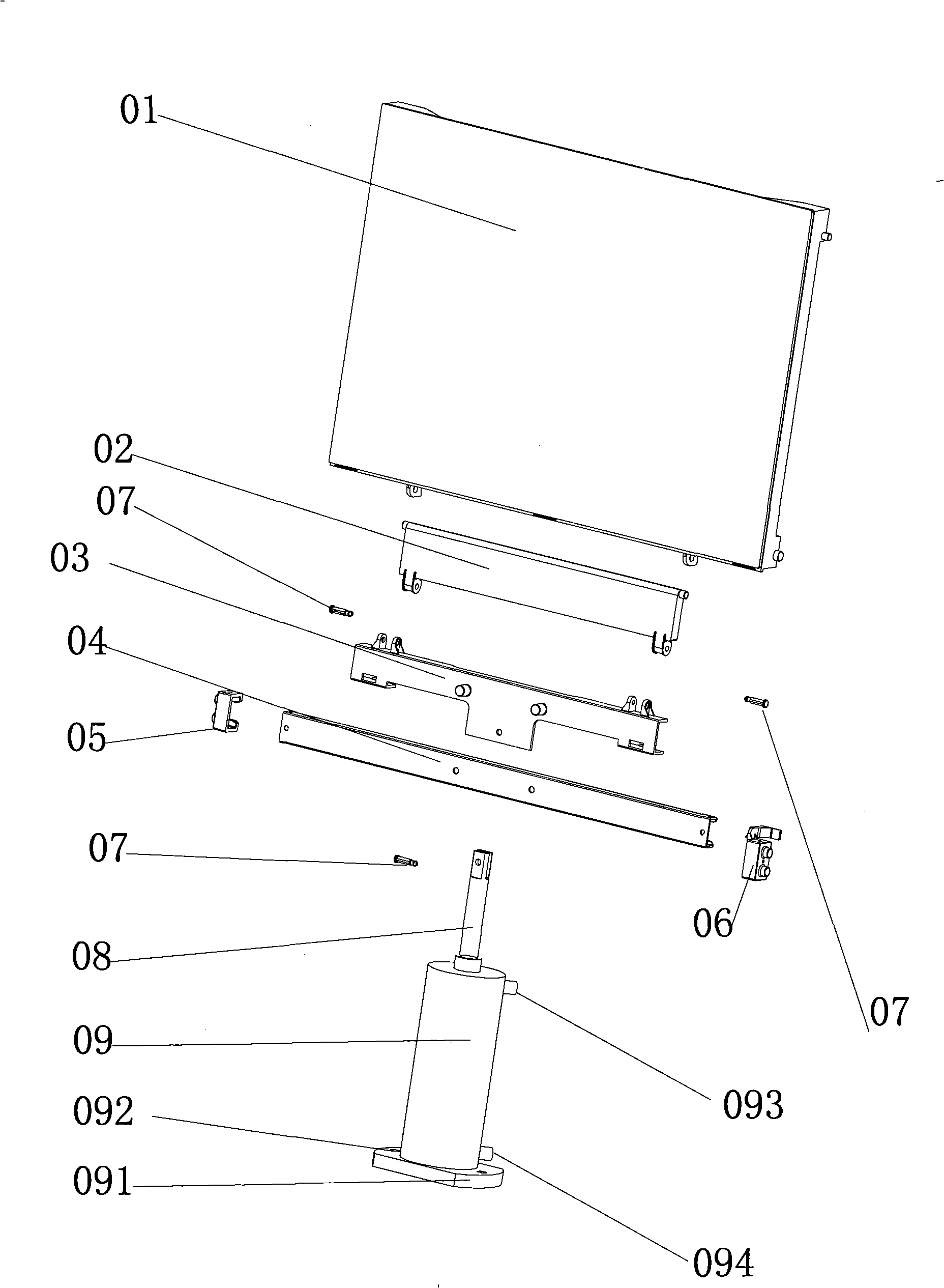

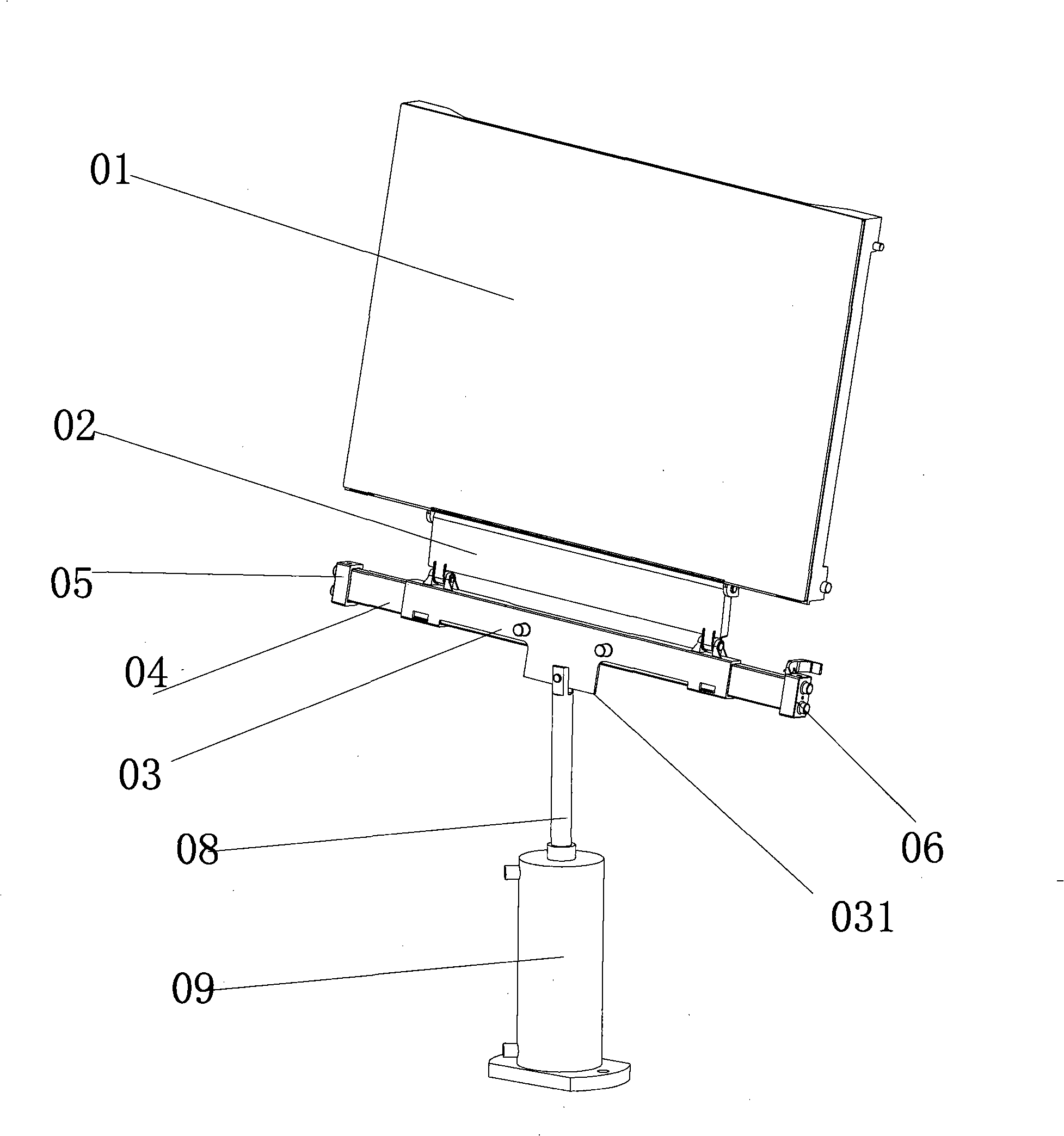

State switching method and electronic apparatus

InactiveCN103517138AImprove efficiencyEasy to operateSelective content distributionOperating instructionState switching

The invention provides a state switching method and an electronic apparatus. The state switching method comprises the following steps that: an operating instruction for starting an information acquisition device is acquired, and first feature information in a preset range is acquired through the information acquisition device; whether preset feature information exists in the first feature information is judged, and a first judgment result is generated; and whether the electronic apparatus is switched from a first operating state to a second operating state is determined according to the first judgment result. Thus, with the state switching method and the electronic apparatus of the invention adopted, the electronic apparatus can be automatically powered off when a user leaves away or falls asleep, and therefore, the operation of the user can be convenient; power consumption can be gradually reduced before shutdown; and therefore, the shutdown will not affect user experience, and the power consumption of the electronic apparatus can be effectively reduced, and the use efficiency of the electronic apparatus can be improved.

Owner:LENOVO (BEIJING) CO LTD

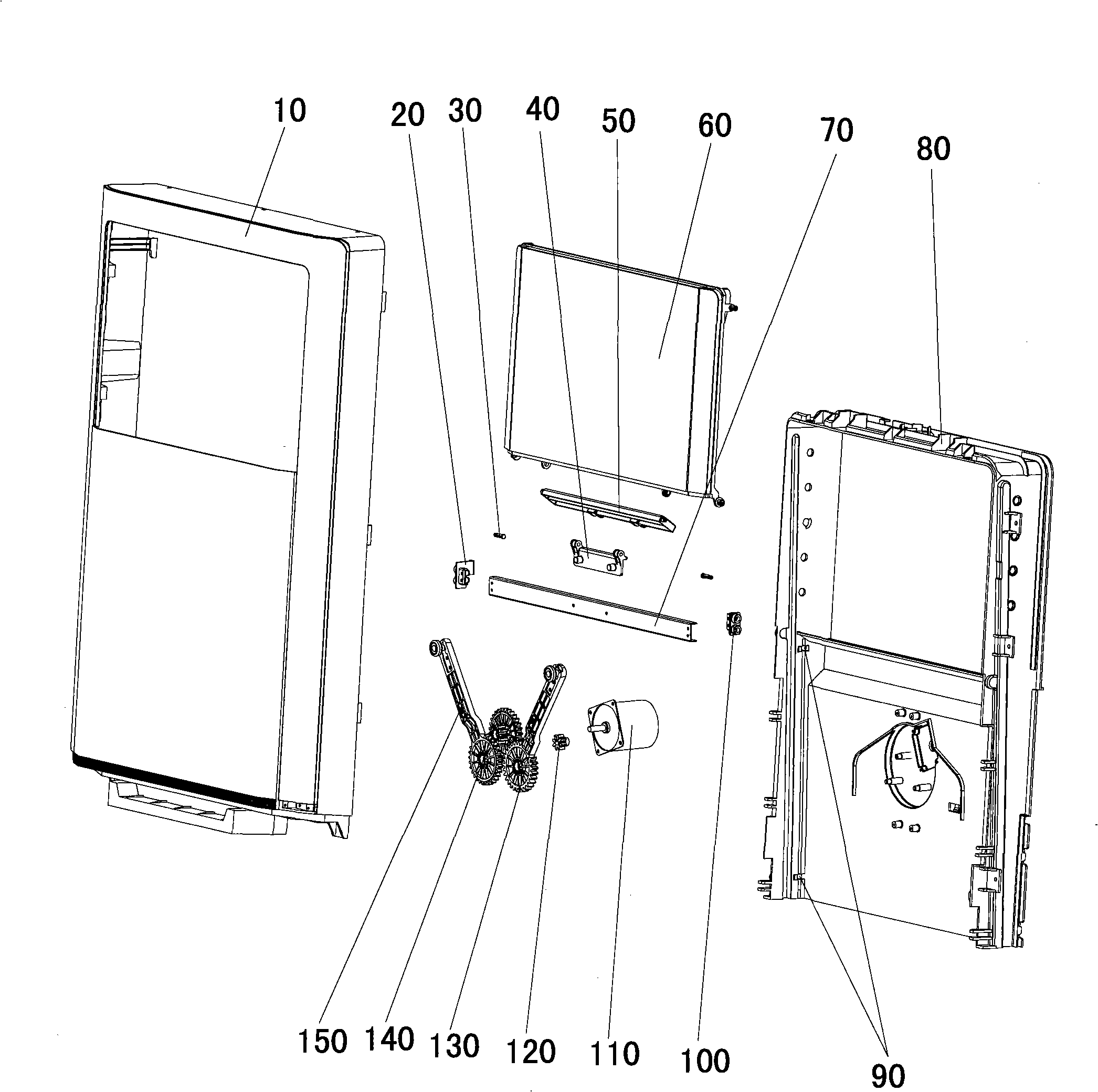

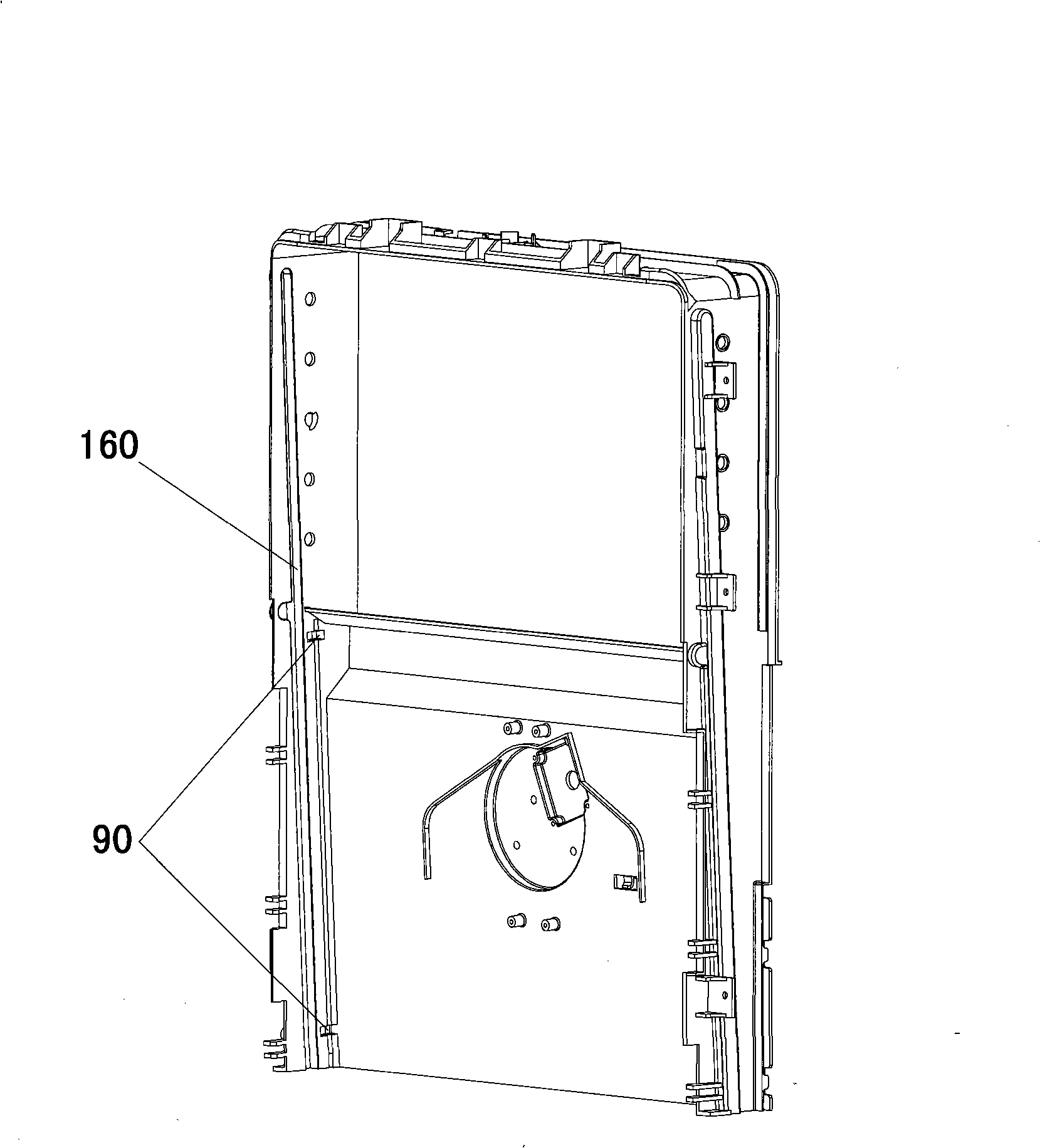

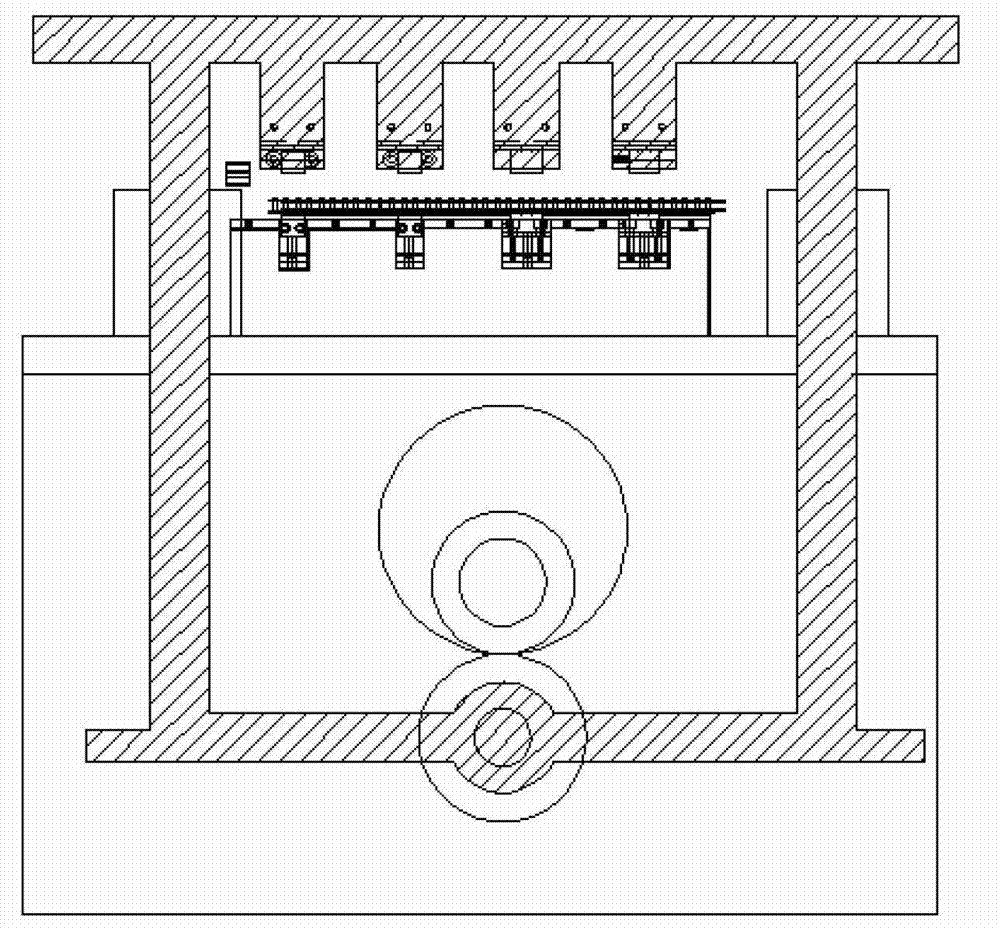

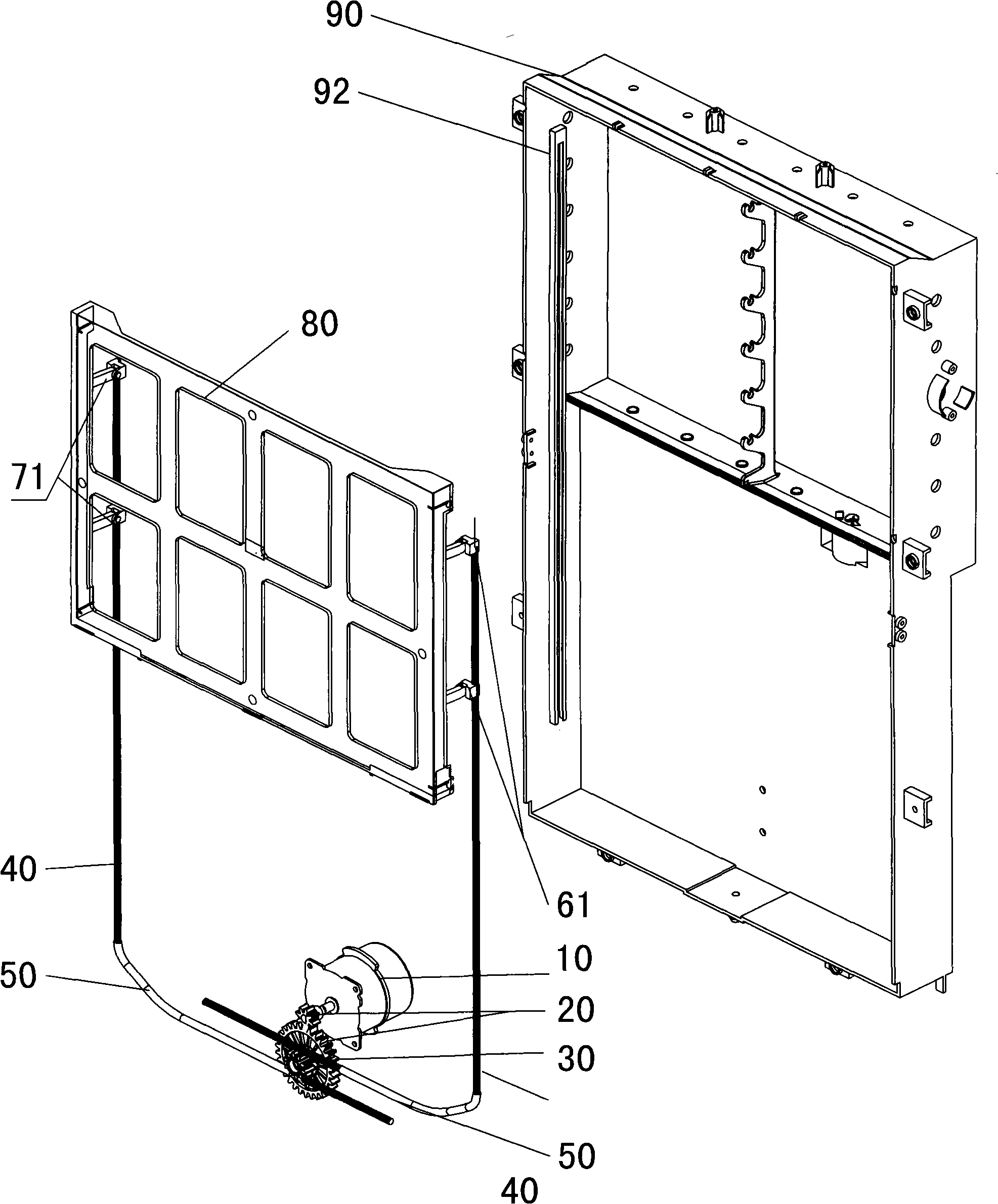

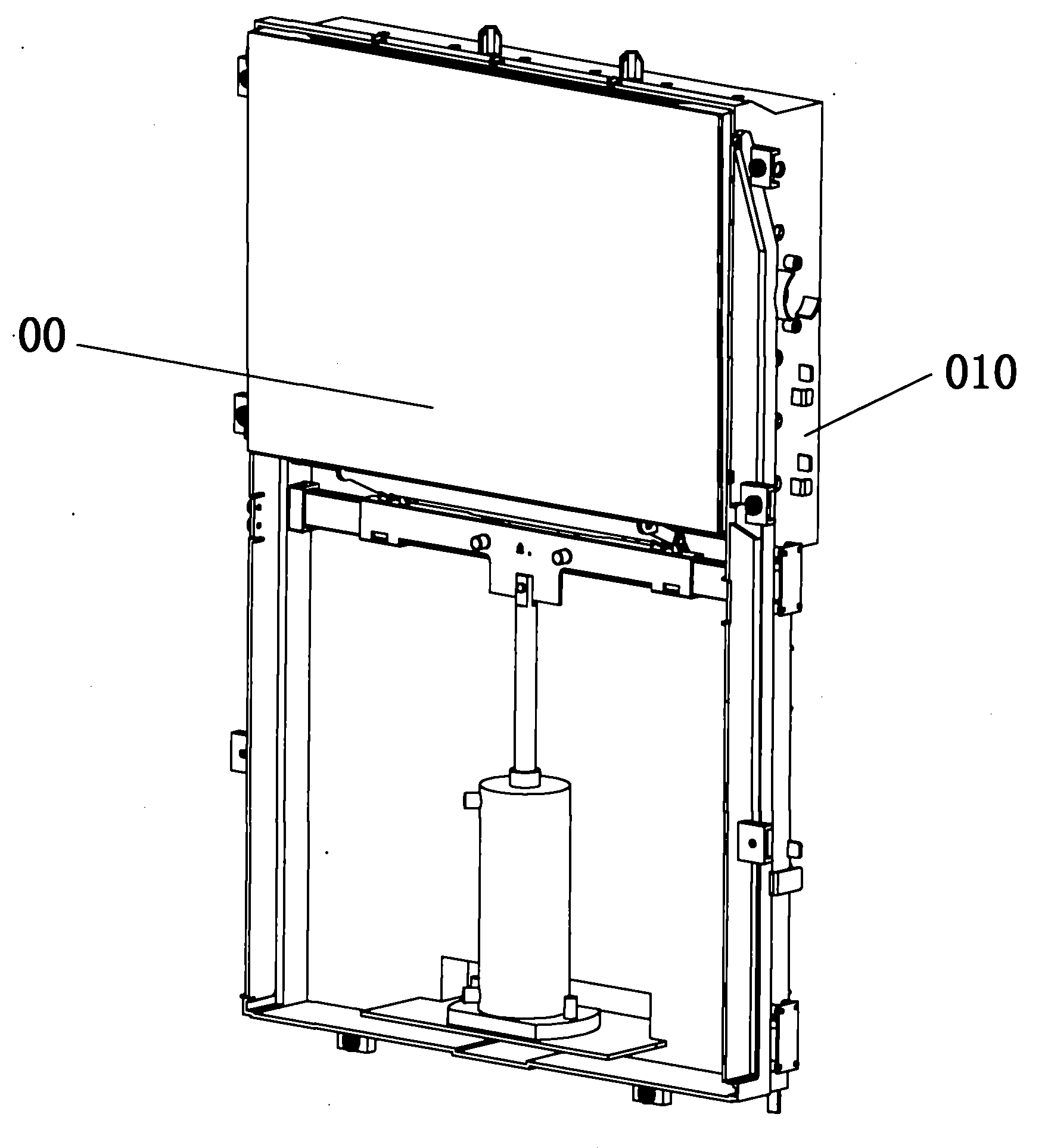

Cabinet air conditioner with exhaust port sliding door

ActiveCN101344284ARealize automatic shutdownGuaranteed aestheticsLighting and heating apparatusPower-operated mechanismHydraulic cylinderEngineering

The invention provides a cabinet air conditioner which is provided with an automatic door at an exhaust port, has simple structure, low cost, smooth slide and can be conductive to the market competition and ensure long-term effective use, and the cabinet air conditioner can optimize the problems of noise and stability of the sliding door of the cabinet air conditioner during sliding. The cabinet air conditioner comprises: a cabinet body of the air conditioner, an upper panel body, a lower panel body, a sliding door part, a door drive device and an air outlet frame, wherein, the door drive device comprises a hydraulic transmission device and a connecting plate device; the hydraulic transmission device and the connecting plate device are positioned at the bottom part of the sliding door; the hydraulic transmission device comprises a hydraulic cylinder and a piston which is positioned at the position of an opening at the top surface of the hydraulic cylinder and can move up and down; the top part of the connecting plate device is connected with the bottom part of the sliding door in a fastening way, and the bottom part of the connecting plate device is connected with the piston by a fastening device.

Owner:GREE ELECTRICHEFEI

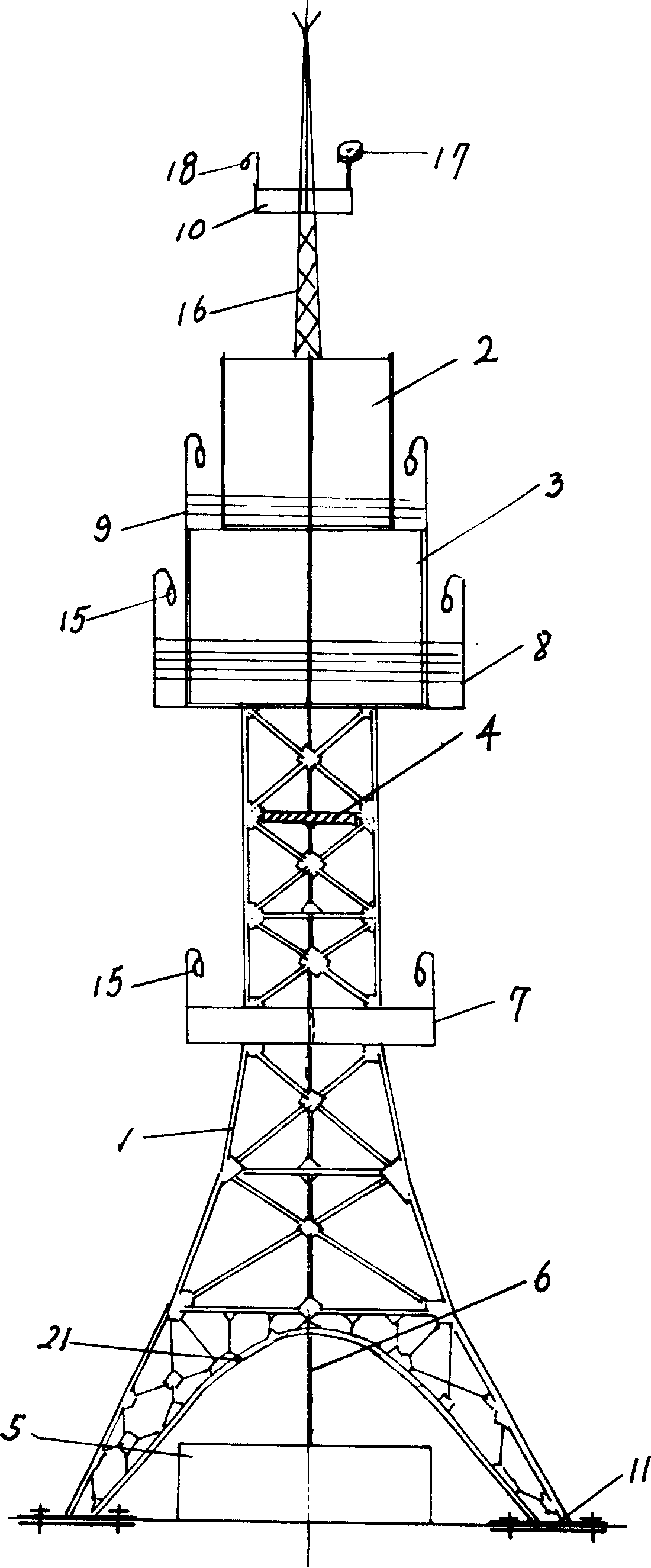

Wind driven power generator

InactiveCN1421605AGuaranteed stabilitySimple structureWind motor combinationsMachines/enginesWind drivenElectricity

The wind driven generator includes tower part, which consists of S-shaped starting wind wheel and circular operating wind wheel fixed to the vertical wind wheel shaft, and electric generators, which is on the ground and has input shaft connected to the vertical wind wheel shaft. The operating wind wheel has friction sheets on two ends and the friction sheets are fixed to the piston of hydraulic cylinder fixed on the tower. The S-shaped starting wind wheel makes the wind driven generator capable of being driven by wind from all directions. The present invention has the advantages of stable operation, high electricity generating efficiency, etc.

Owner:曲敬辉

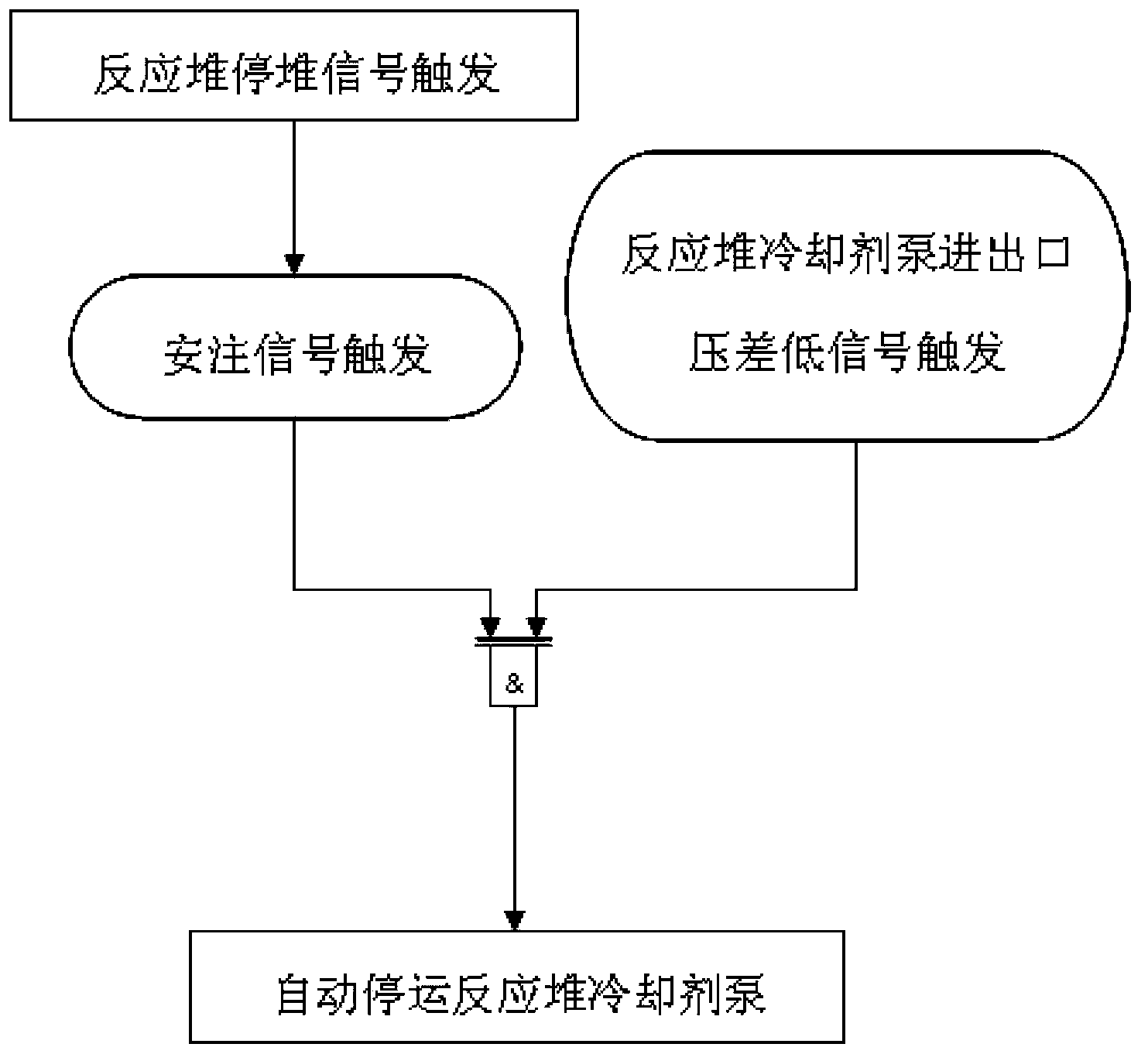

Method for automatically stopping coolant pump under reactor coolant loss accident condition

ActiveCN104332207ARealize automatic shutdownExtension of timePower plant safety arrangementNuclear energy generationPressurized water reactorNuclear engineering

The invention belongs to a coping method for pressurized water reactor nuclear power station accidents and especially relates to a method for automatically stopping a coolant pump under the reactor coolant loss accident condition. The method comprises the following steps: the step 1) triggering a safe injection signal and a reactor coolant pump inlet and outlet pressure difference low logic; and the step 2) when the safe injection signal coexists with the condition of reactor coolant pump inlet and outlet low pressure difference, triggering the reactor coolant pump to stop operation. The method has the advantages that the method can realize automatic shutdown of the reactor coolant pump before reactor core deterioration under the LOCA condition, and the time when operators do not need to intervene the accident is prolonged greatly.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

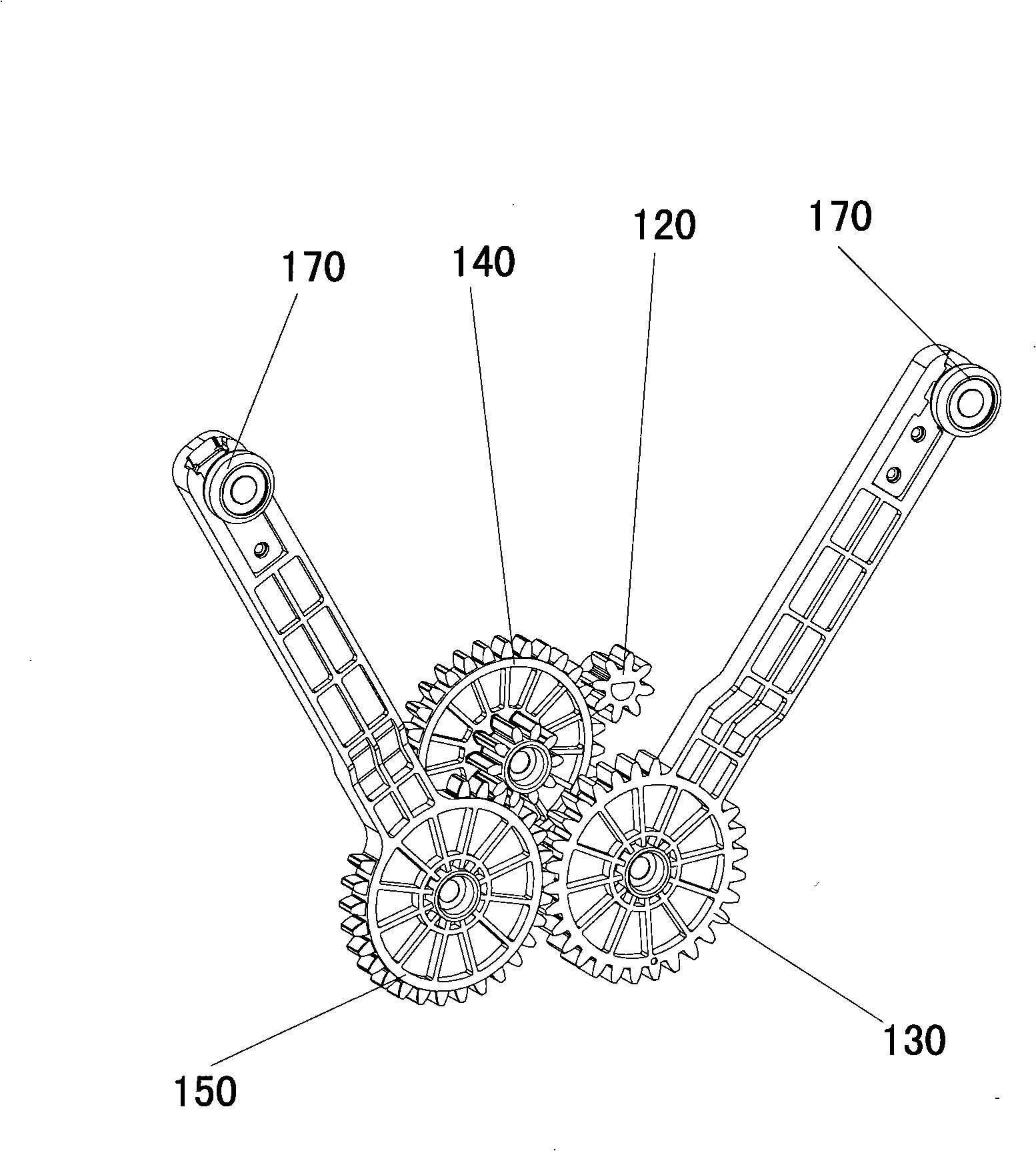

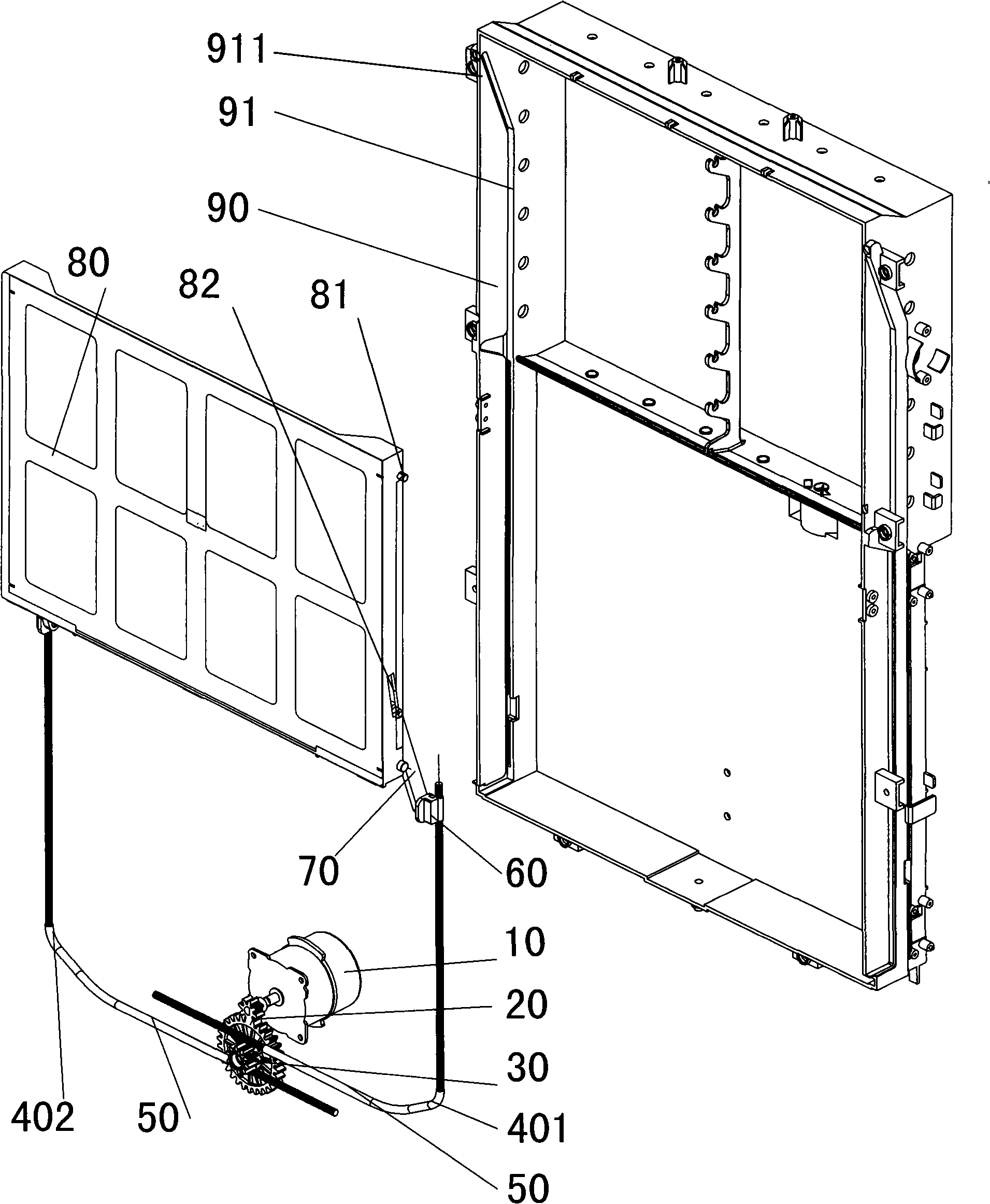

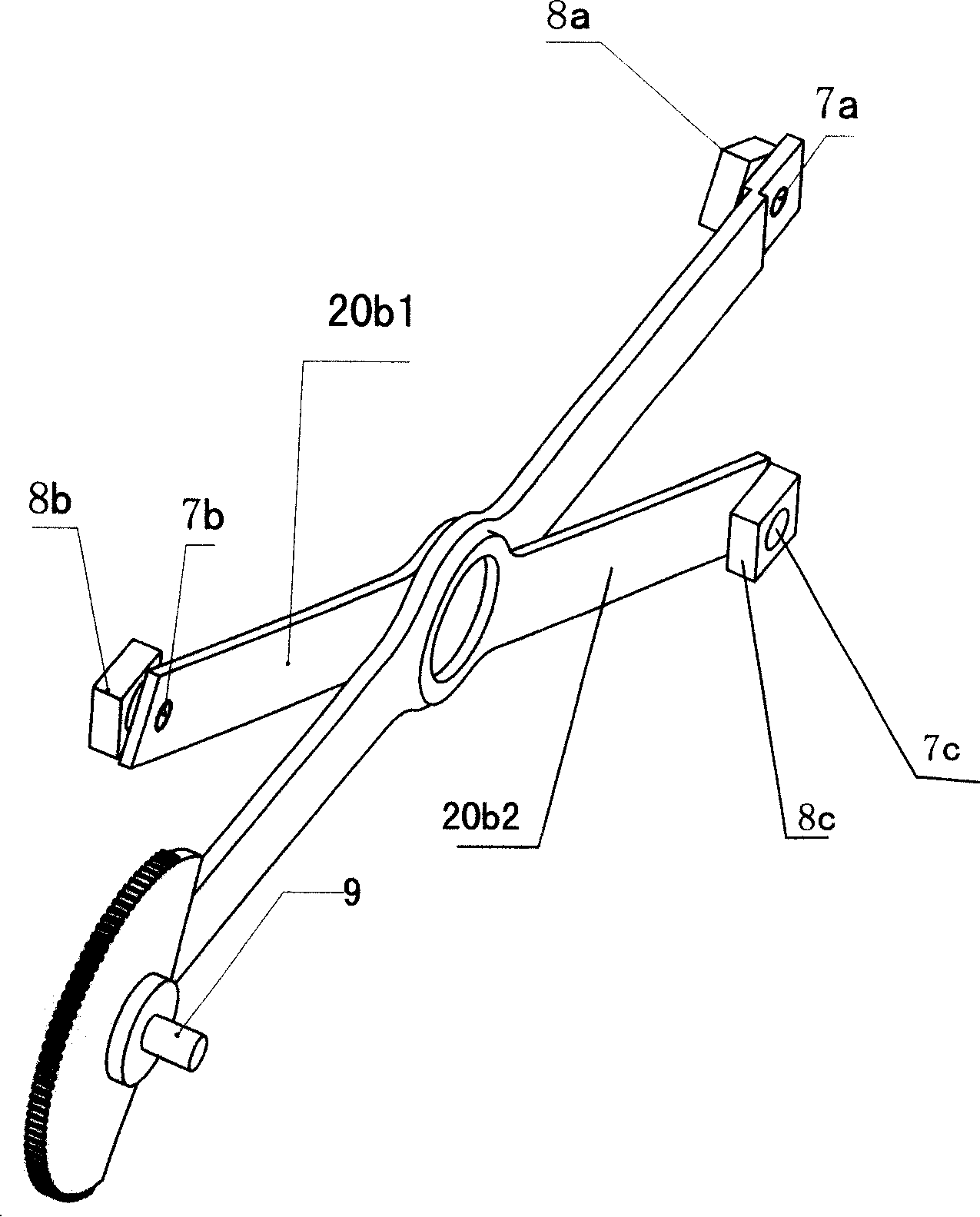

Cabinet air conditioner with exhaust port sliding door

ActiveCN101344285ARealize automatic shutdownGuaranteed aestheticsLighting and heating apparatusPower-operated mechanismEngineeringMarket competition

The invention provides a cabinet air conditioner which is provided with an automatic door at an exhaust port, has simple structure, low cost, smooth slide and can be conductive to the market competition and ensure long-term effective use. The cabinet air conditioner comprises: a cabinet body of the air conditioner, an upper panel body, a lower panel body, a sliding door part, a door drive device and an air outlet frame, wherein, the door drive device comprises a gear set part and a transmission mechanism; the door drive device is connected with the bottom part of the sliding door; the gear set part comprises a power wheel which is connected with a motor, a duplicate gear which can convert rate and two connecting rod balance wheels provided with swing rods, the two connecting rod balance wheels are symmetric at the left and the right by taking a vertical line as a central line; the transmission mechanism comprises a sliding track which is connected with the outer ends of the swing rods of the connecting rod balance wheels and is arranged horizontally and a connecting plate device which is connected with the sliding track and the bottom part of the sliding door.

Owner:GREE ELECTRIC APPLIANCES INC

Chain riveting method utilizing oil pressure

ActiveCN102861864AFlexible adjustmentEasy to detect and cut offMetal chainsHydraulic cylinderChain link

A chain riveting method utilizing oil pressure includes step 1, placing a chain with pins into a chain passage, aligning a first chain link required to be riveted to a riveting die; step 2, starting a hydraulic cylinder and a moving plate driving device by a control device, and enabling the hydraulic cylinder to drive the riveting die to realize primary riveting; step 3, driving a moving plate to drive the chain to move by the moving plate driving device after finishing the primary riveting; and step 4, repeating the step 2 and the step 3 to complete riveting of the whole chain. By combination of a PLC control device and an oil pressure system, full-automatic, intelligent and multifunctional riveting can be realized, four-side riveting and two-side riveting can be realized, and by the chain riveting method, one link of the whole chain can be free of riveting while the other links are riveted, so that the chain can be cut off conveniently for subsequent detection.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

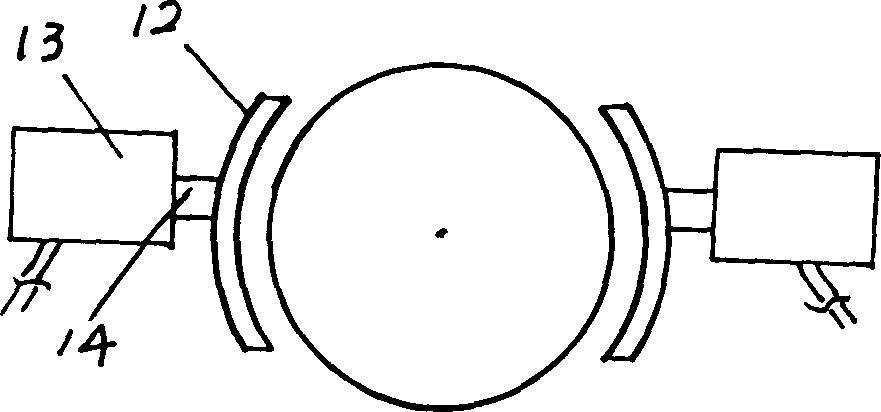

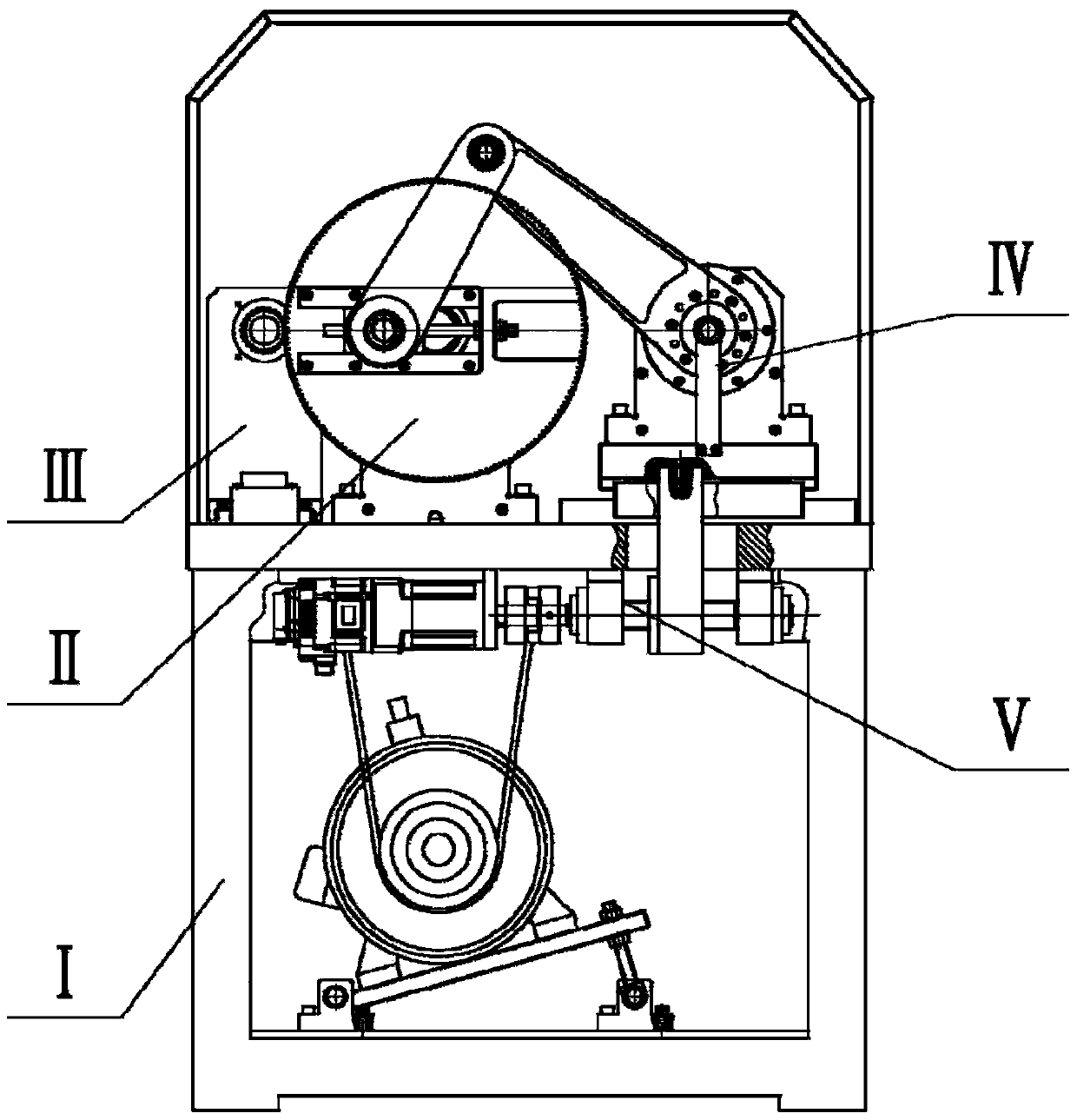

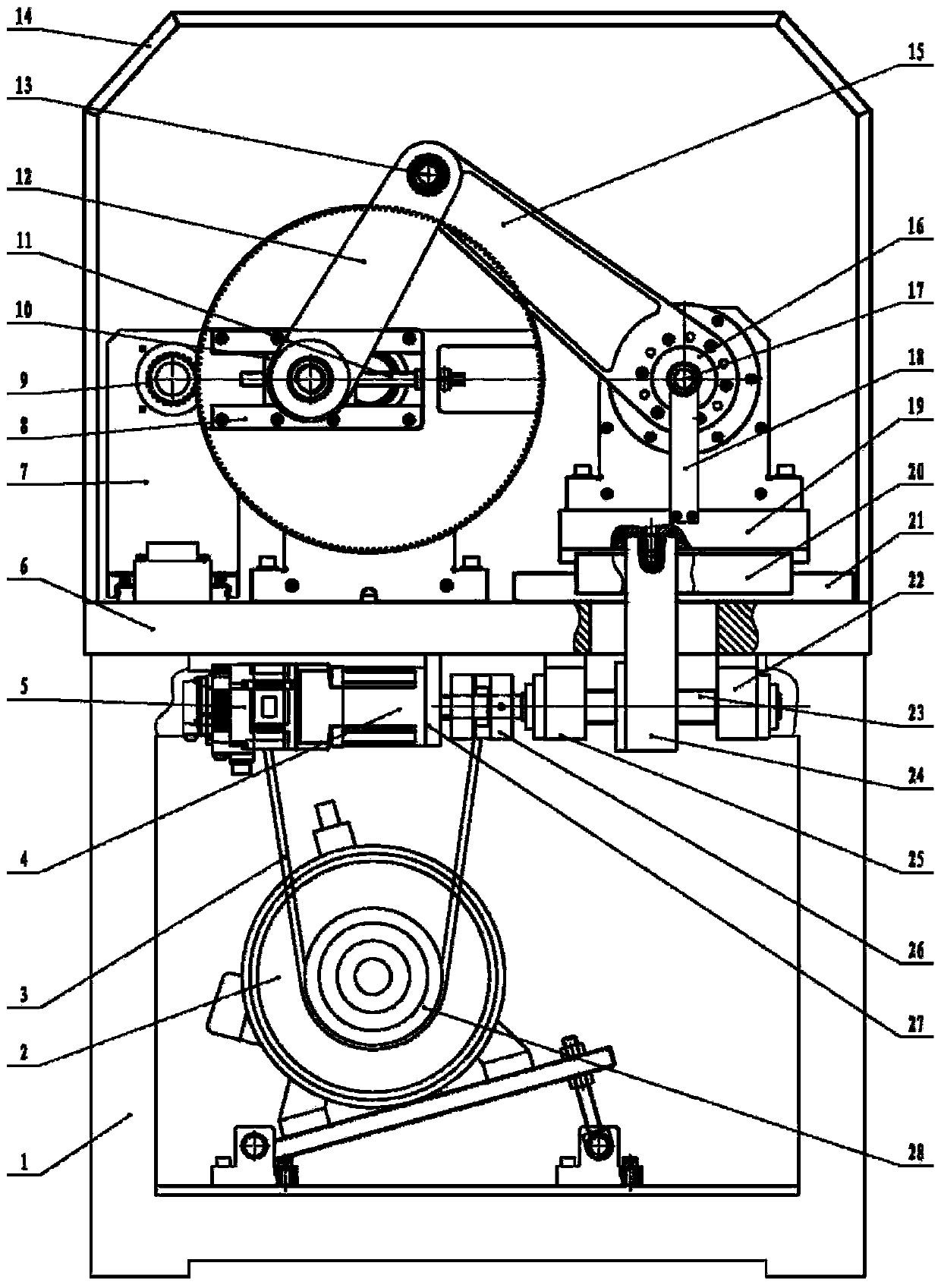

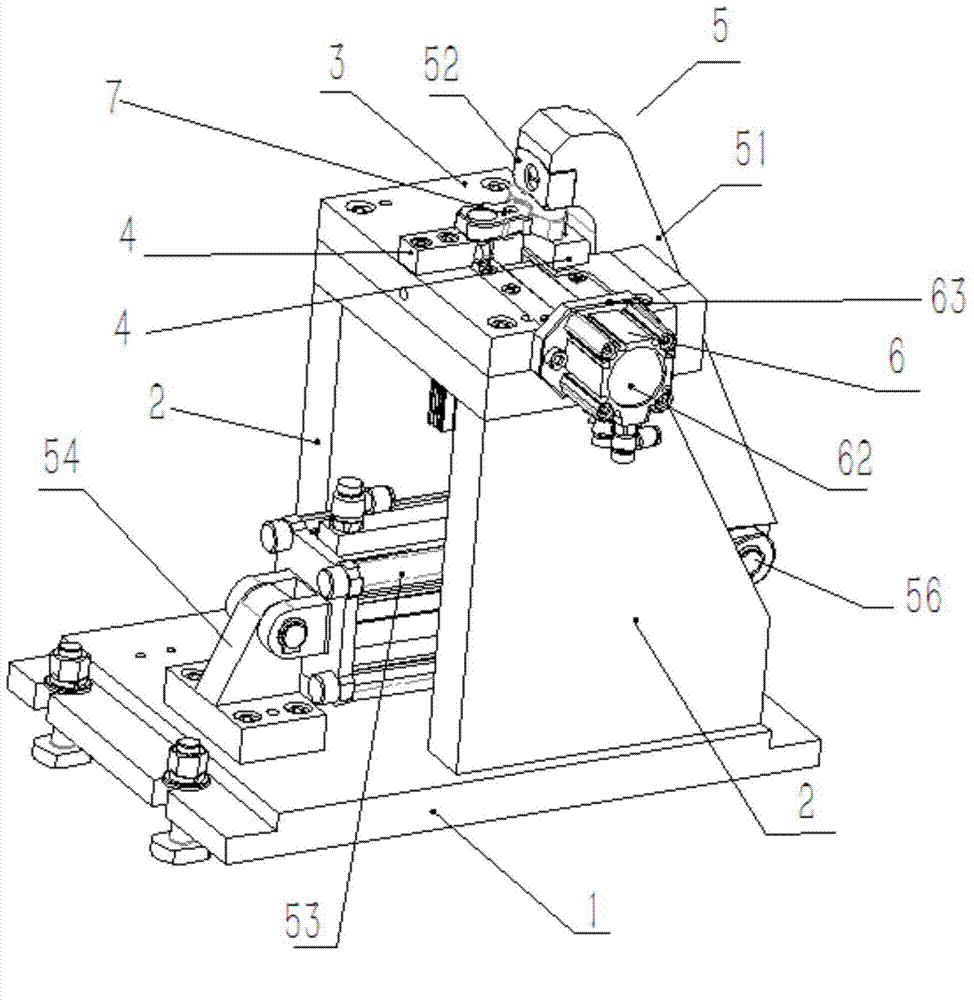

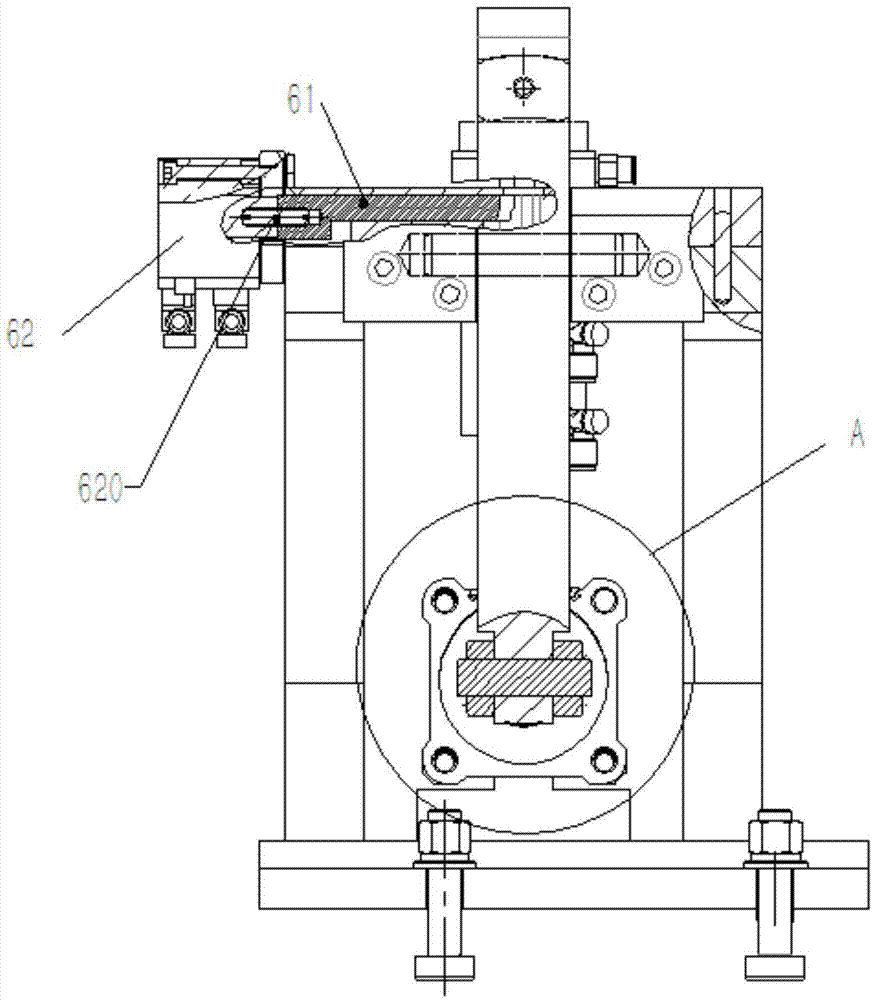

Torsion durability fixed torque testing machine for automobile dry friction type clutch driven plate assembly

PendingCN110031235ASimple structureEasy to useVehicle testingMachine gearing/transmission testingClutchObservational error

The invention discloses a torsion durability fixed torque testing machine for an automobile dry friction type clutch driven plate assembly, which mainly comprises a base, a driving mechanism, a manualdriving loading mechanism, a torsion mechanism, a compensation mechanism and an aligning mechanism, wherein the driving mechanism, the manual driving loading mechanism, the torsion mechanism and thecompensation mechanism are respectively fixed on the base, and the aligning mechanism is fixed on the torsion mechanism; the base is provided with a frame on which a variable frequency motor is fixed;a small belt wheel is arranged on the output shaft of the variable frequency motor and transmitts power to the large belt wheel of the driving mechanism through the V-ribbed belt; a bedplate is fixedon the frame through a screw, and an outer frame is fixed on the bedplate. According to the invention, the automatic compensation of the test torque is realized; the testing machine can monitor in real time, judge when a product is invalid and realize automatic shutdown in a durability test; the measurement error caused by the clearance between the spline shaft and the spline hole of the tested workpiece is eliminated in the experimental process; the testing machine is simple and novel in structure and convenient in operation.

Owner:ZHEJIANG TIELIU CLUTCH

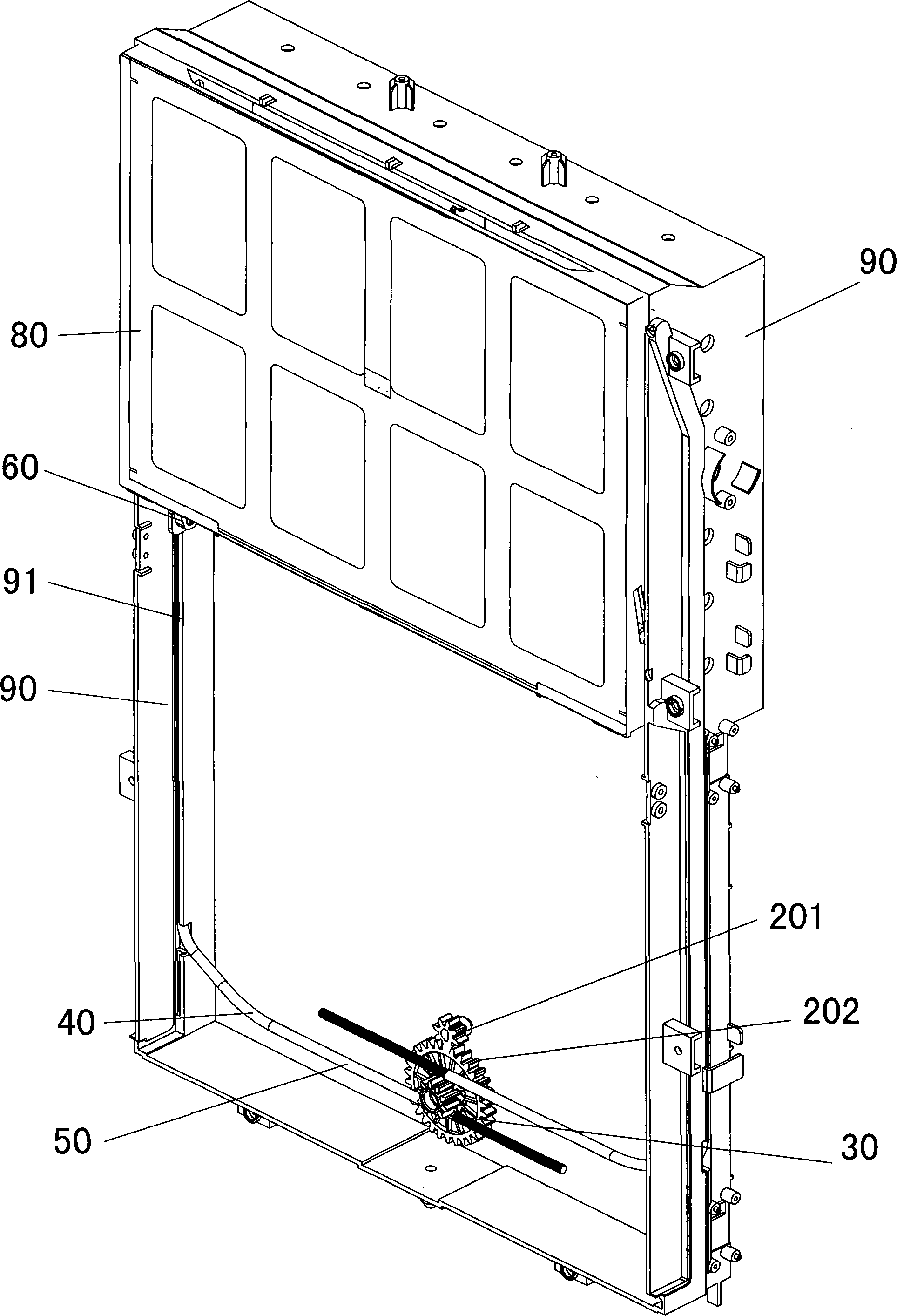

Cabinet air conditioner with exhaust port sliding door

ActiveCN101358755ARealize automatic shutdownGuaranteed aestheticsLighting and heating apparatusHeating and ventilation casings/coversDrive motorEngineering

The present invention provides a cabinet-typed air conditioner that has simple structure, low cost and stable sliding, and favors the market competition, and can guarantee the long-term effective application, and is provided with an air discharging port automatic door. The air conditioner comprises an air-conditioning cabinet body, an upper panel body, a lower panel body, a sliding door part, a door driving device and a ventilating frame, wherein, the door driving device comprises a driving motor, a gear reduction box and a worm screw device; the gear reduction box is connected with the driving motor; the worm gear of the worm screw device is installed on an output shaft of the gear reduction box; the worm screw of the worm screw device is a bendable flexible worm screw; one end of the flexible worm screw is engaged with the worm, and the other end is connected with the sliding door through a connection device.

Owner:GREE ELECTRIC APPLIANCES INC

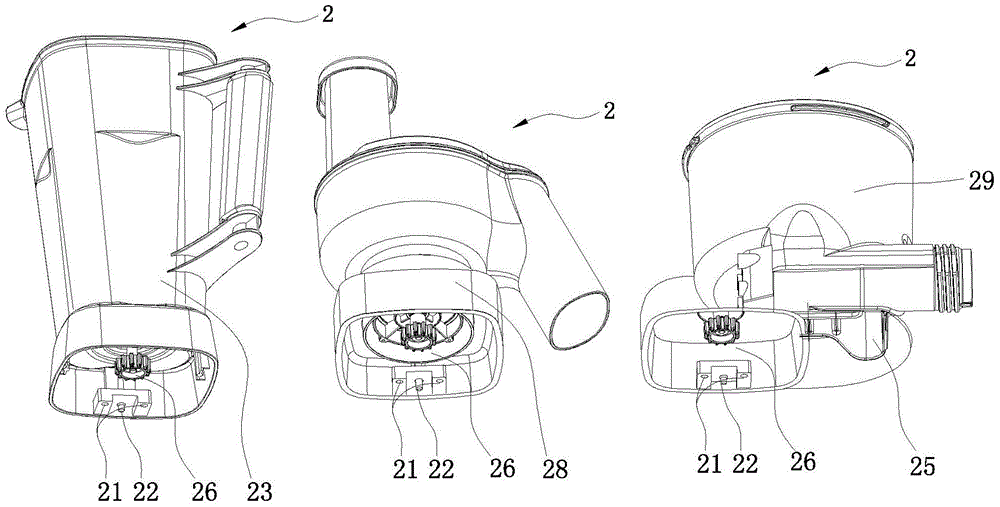

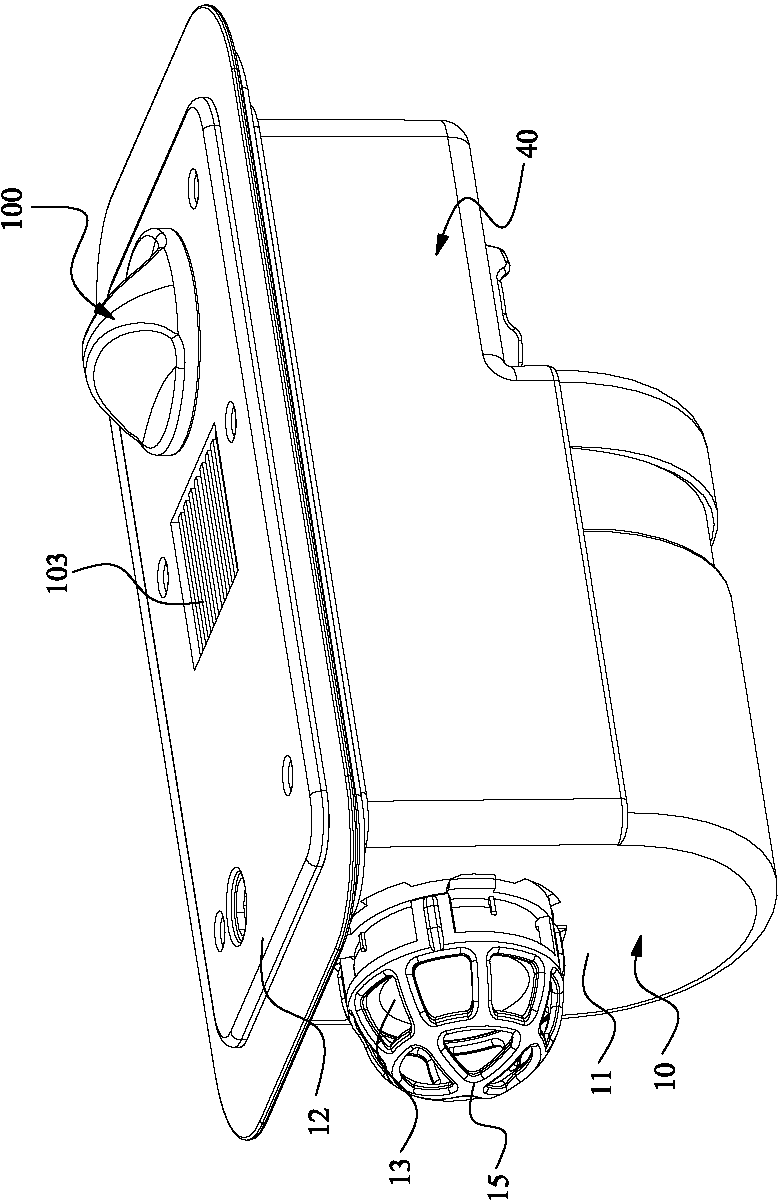

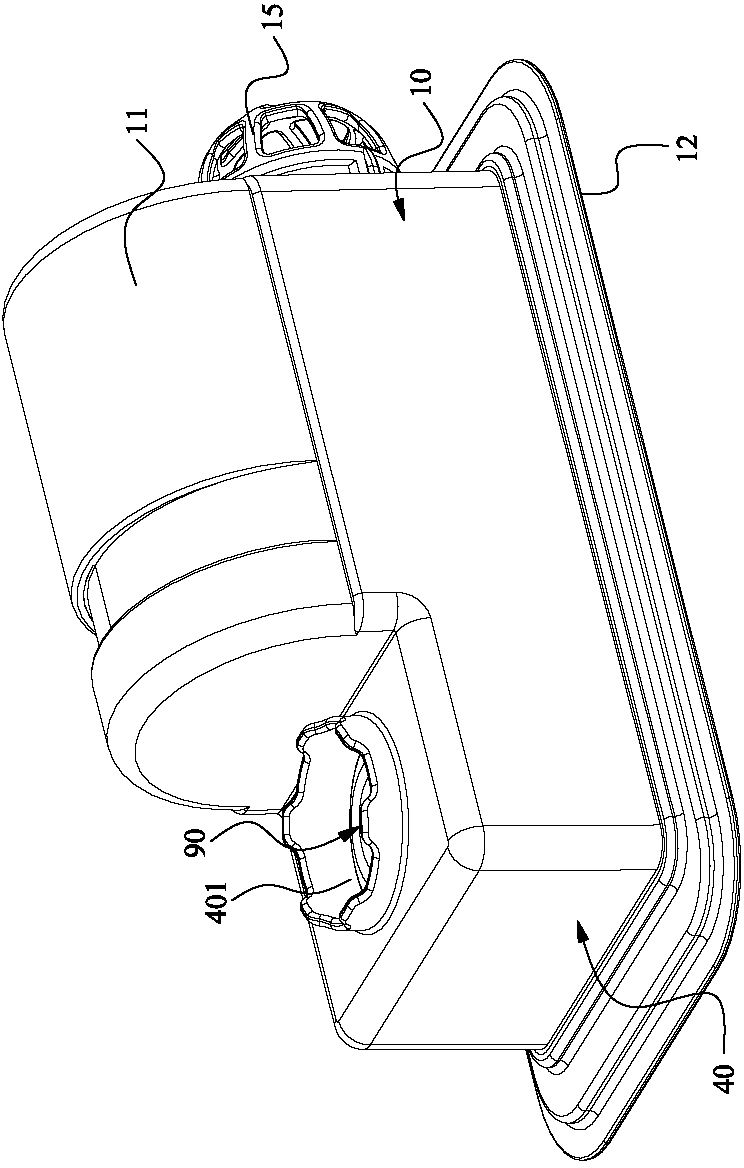

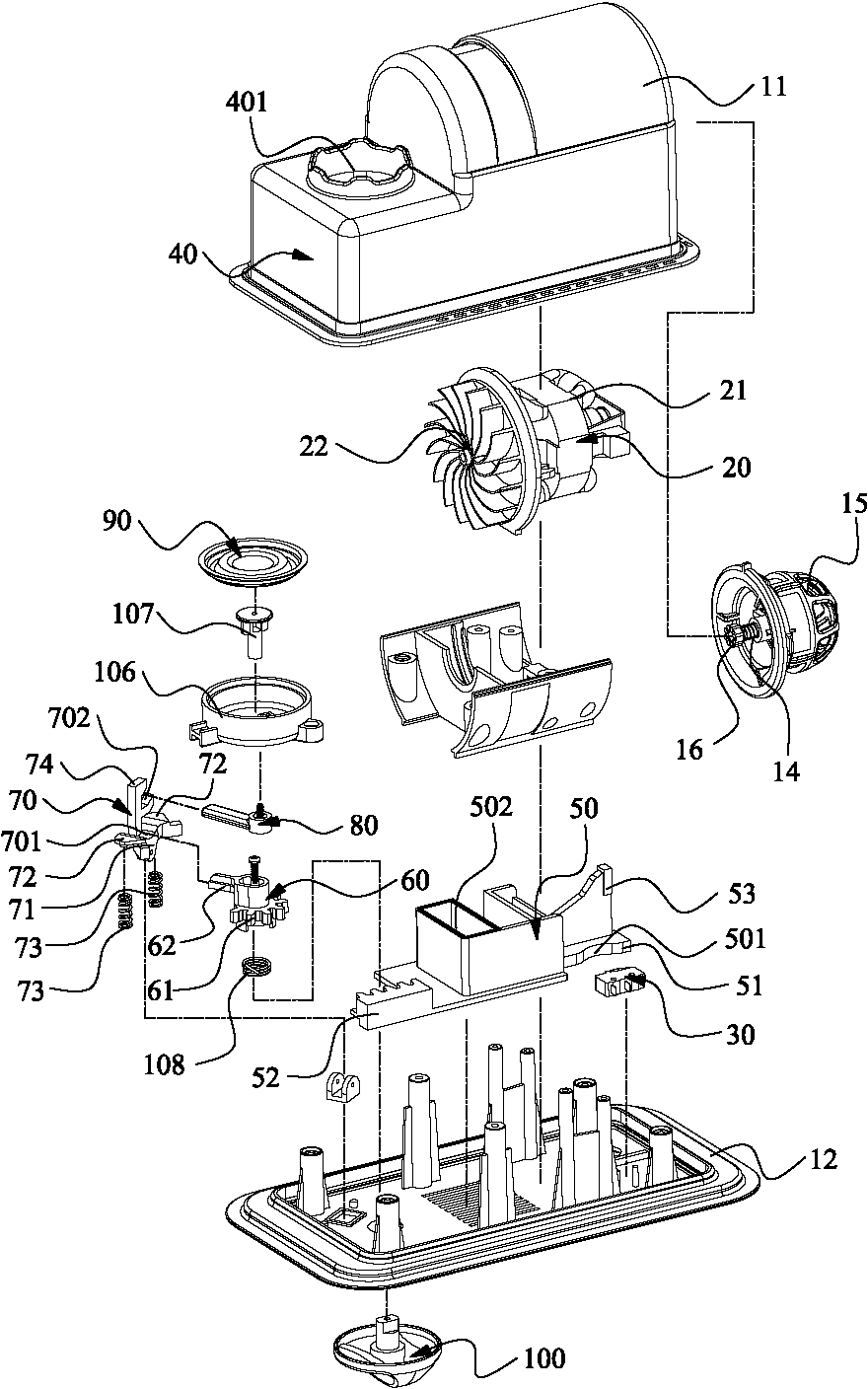

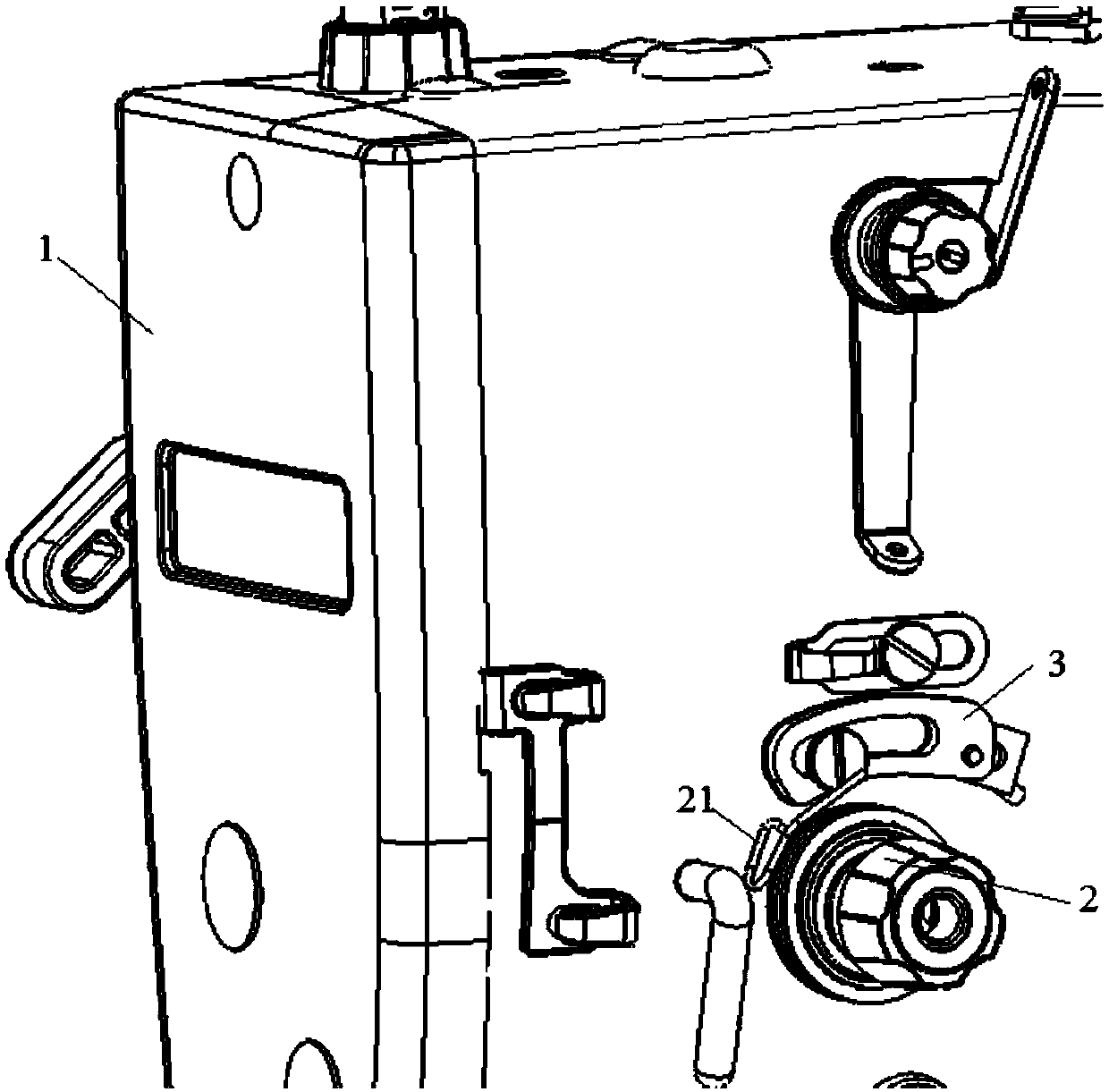

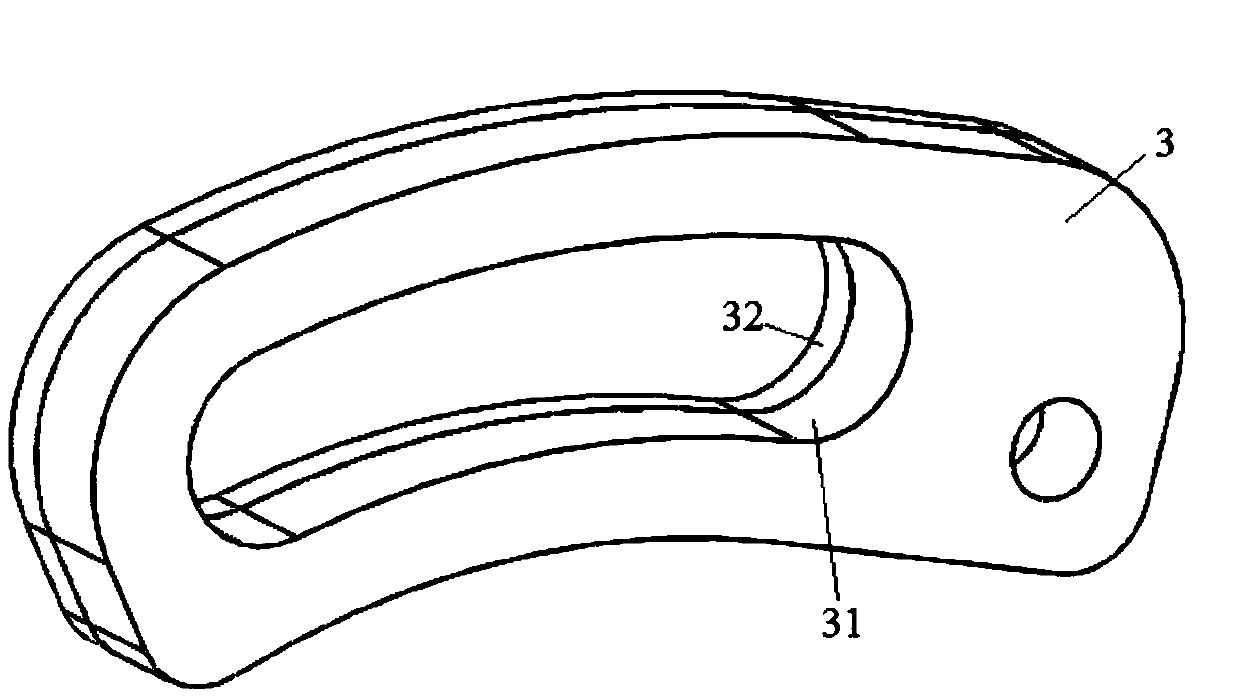

Automatic stop controller and air pump using same

ActiveCN103075357AEasy to manufactureEasy to assemblePump componentsPump controlPressure senseAir pump

The invention discloses an automatic stop controller and an air pump using the automatic stop controller. The air pump comprises a housing, a blower device, a microswitch and an automatic stop controller. The automatic stop controller comprises an outer housing, a moving part, a gear part, a swinging part, a moving ejector rob, a deformable air pressure sensing thin film and a knob, wherein the air pressure sensing thin film deforms to enable the moving ejector rob to move by using the change of the air pressure, the swinging part is enabled to swing due to the movement of the moving ejector rob, the gear part is enabled to rotate due to the swinging of the swinging part, the moving part is enabled to move due to the rotation of the gear part, and the microswitch is triggered due to the movement of the moving part, so that the aim of automatic stop can be realized. The invention further has the inventive step and the use convenience, the product has the characteristics of being intelligent and humanized, and reasonable in structural configuration, the structure of the product can be preferably simplified, each parts in the product is convenient to manufacture and assemble, and the effects of production efficiency improving and production cost reducing can be achieved.

Owner:DONGGUAN TIGER POINT METAL & PLASTIC PRODS

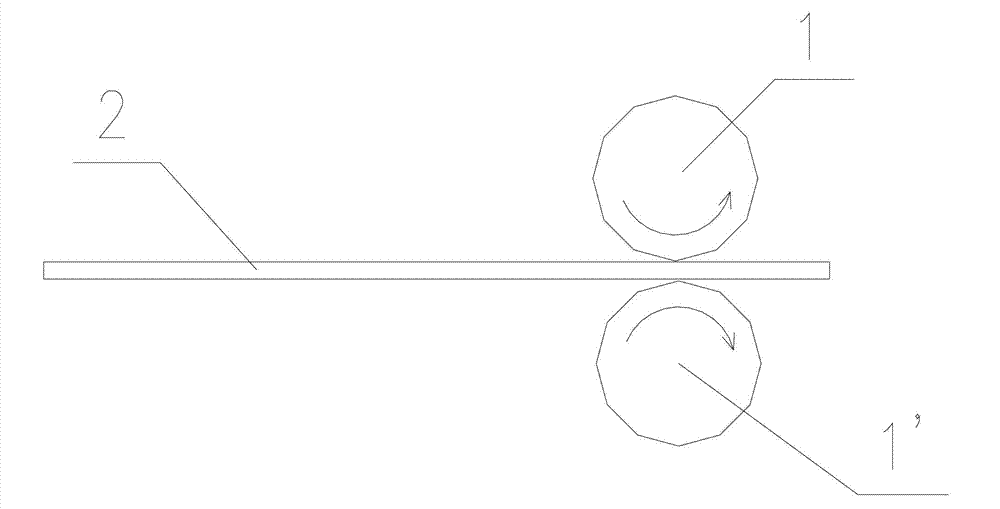

Ironing machine for ties

InactiveCN103161058AConvenient travelRealize automatic bootIroning machinesTextiles and paperElectrical and Electronics engineeringEngineering

An ironing machine for ties comprises at least two elastic compressed rollers, wherein heating layers are arranged on the surfaces of the rollers, heating layers comprise thick film circuit layers which are attached on the rollers and insulating layers which are covered on the thick film circuit layers. Due to the fact that the thick film circuit layers are used for heating, rolling and ironing can be combined together, and space is saved.

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG CO LTD +1

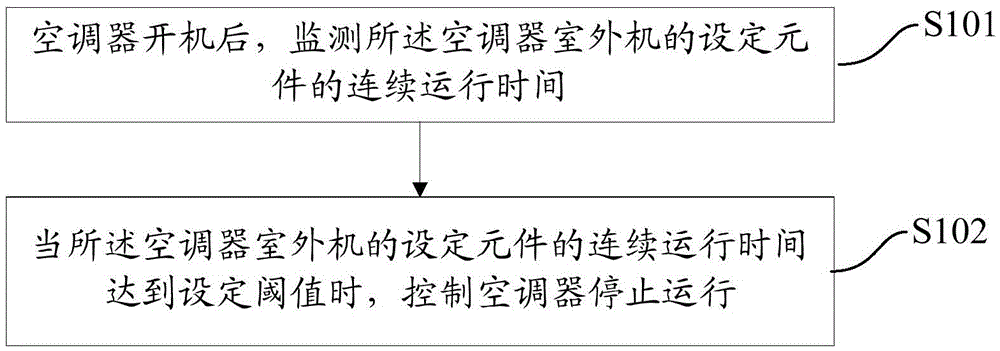

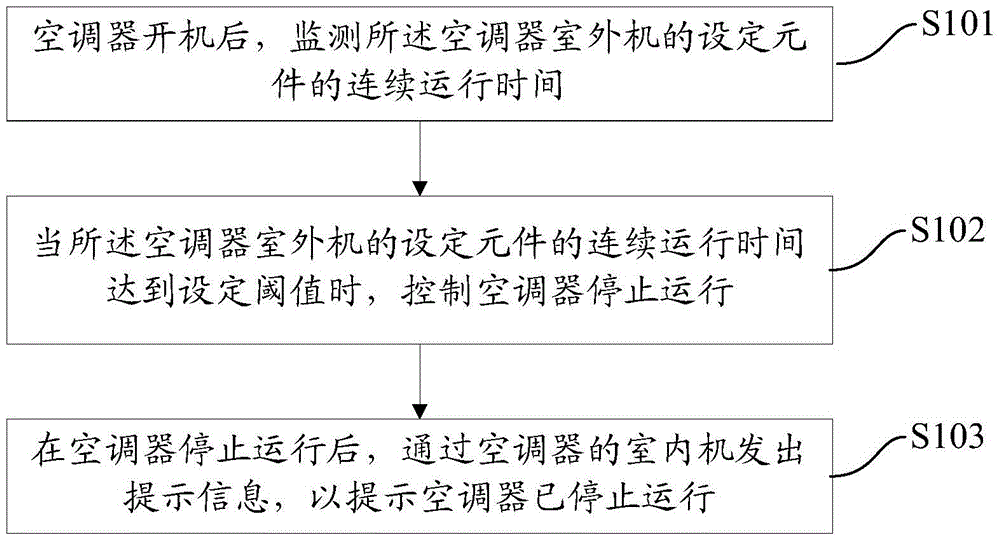

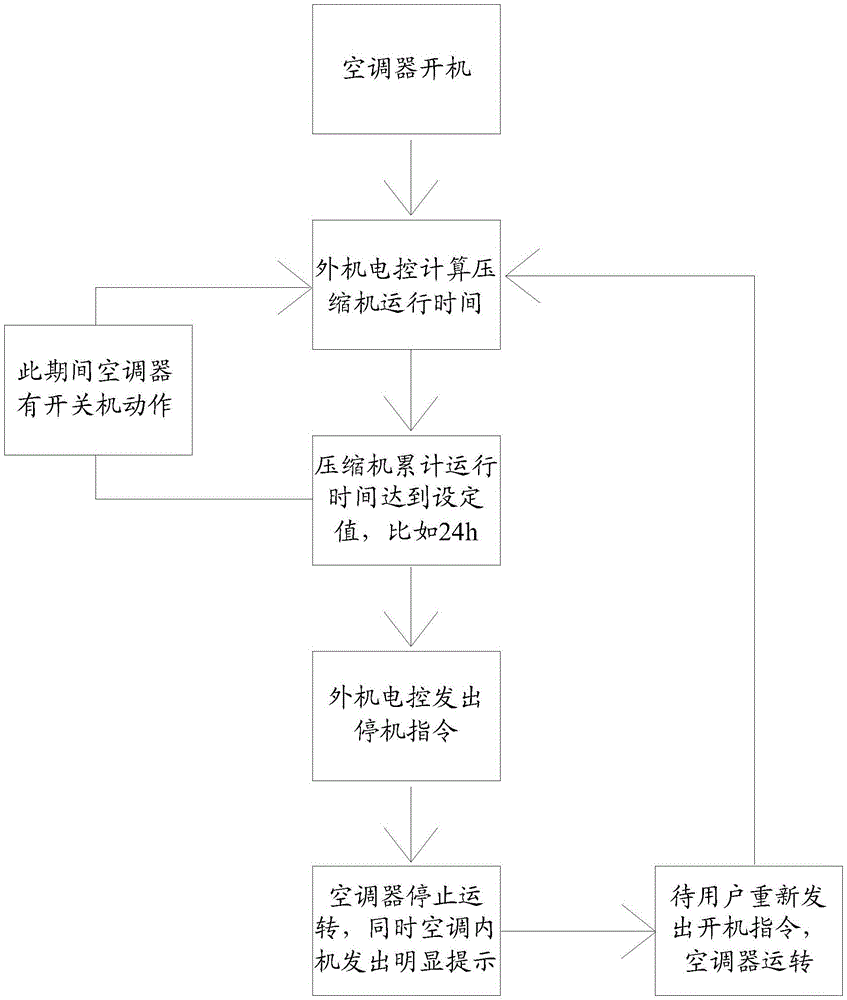

Air conditioner control method and air conditioner

ActiveCN105546769AReduce power wasteRealize automatic shutdownMechanical apparatusSpace heating and ventilation safety systemsContinuous operationControl theory

The invention discloses an air conditioner control method and an air conditioner. The air conditioner control method includes the steps that after the air conditioner is started, continuous operation time of a set component of an air conditioner outdoor unit is monitored; when the continuous operation time of the set component of the air conditioner outdoor unit reaches a set threshold value, the air conditioner is controlled to stop operating. Automatic shutdown of the air conditioner can be achieved without increasing air conditioner cost, normal use of the air conditioner is not affected, and power waste caused when a user forgets to turn off the air conditioner for a long time can be effectively reduced.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP

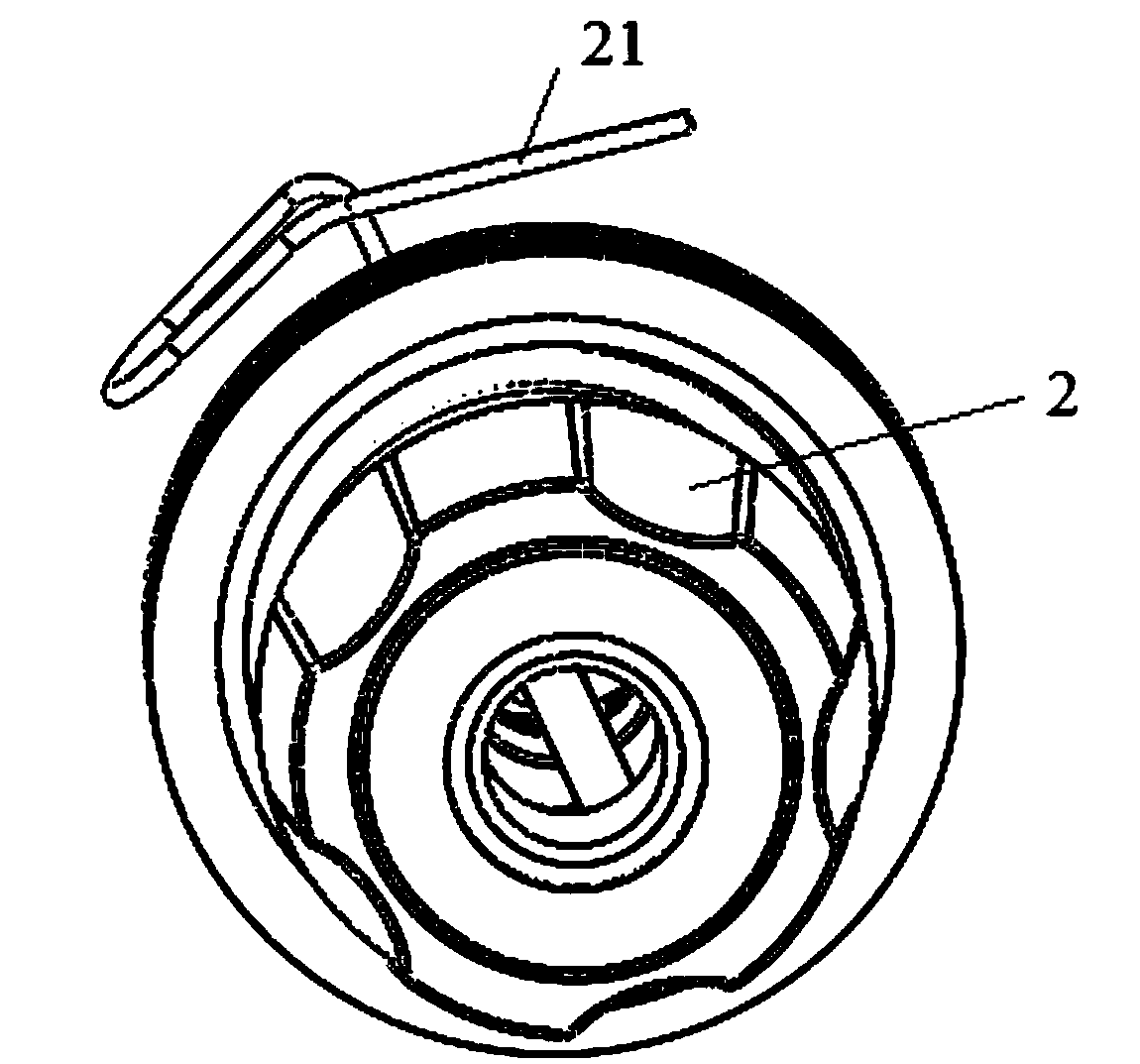

Sewing machine and thread break detection control device thereof

ActiveCN109554845ARealize automatic shutdownImprove sewing effectSewing-machine control devicesThread-break detectorsElectric machineryEngineering

The invention discloses a sewing machine and a thread break detection control device thereof. The thread break detection control device comprises a thread clamp, a thread break detection device and acontroller. The thread clamp is arranged on a shell of the sewing machine and provided with a thread picking spring; the thread picking spring is used for cooperating with a sewing thread in normal sewing of the sewing machine to continuously contact with and separate from the thread break detection device, and thread picking spring and the thread break detection device are in a normally contactedstate in breakage of the sewing thread; the thread break detection device is arranged on the shell and used for generating connection signals when contacting with the thread picking spring and generating disconnection signals when separating from the thread picking spring; the controller is connected with an output end of the thread break detection device and used for determining that the sewingmachine is not in thread break after receiving the disconnection signals and determining thread break of the sewing machine after only receiving the connection signals and controlling halting of a driving motor of the sewing machine, wherein connection and disconnection signals include cyclically generated connection signals and disconnection signals. Therefore, automatic halting of the sewing machine after thread break of the sewing machine is realized, and great sewing effects are achieved.

Owner:JACK SEWING MASCH CO LTD

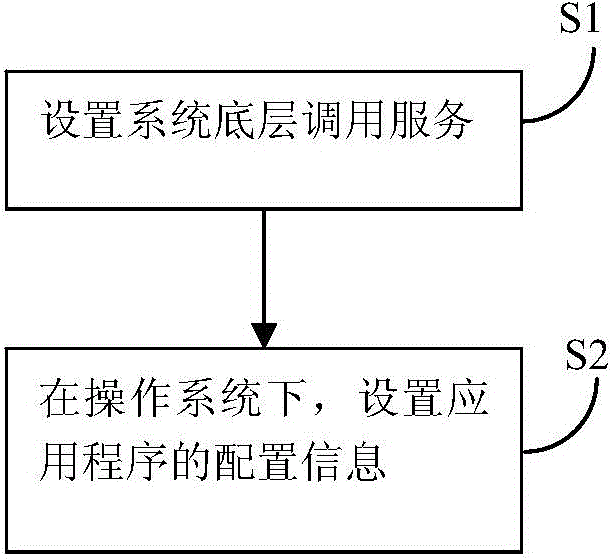

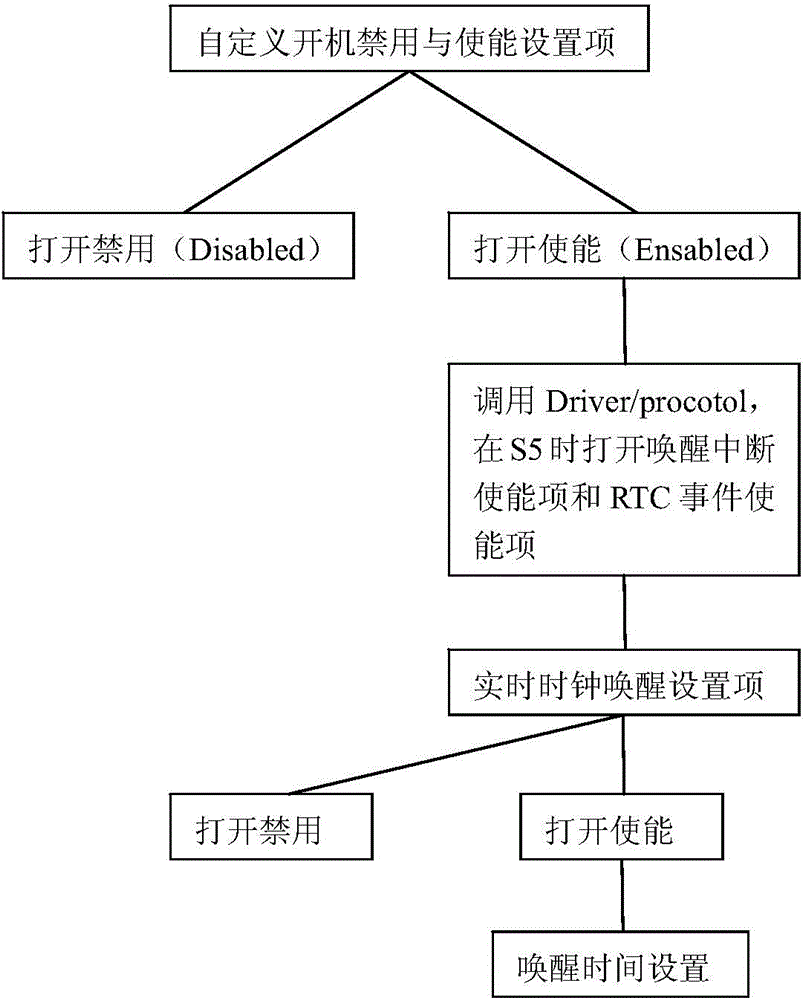

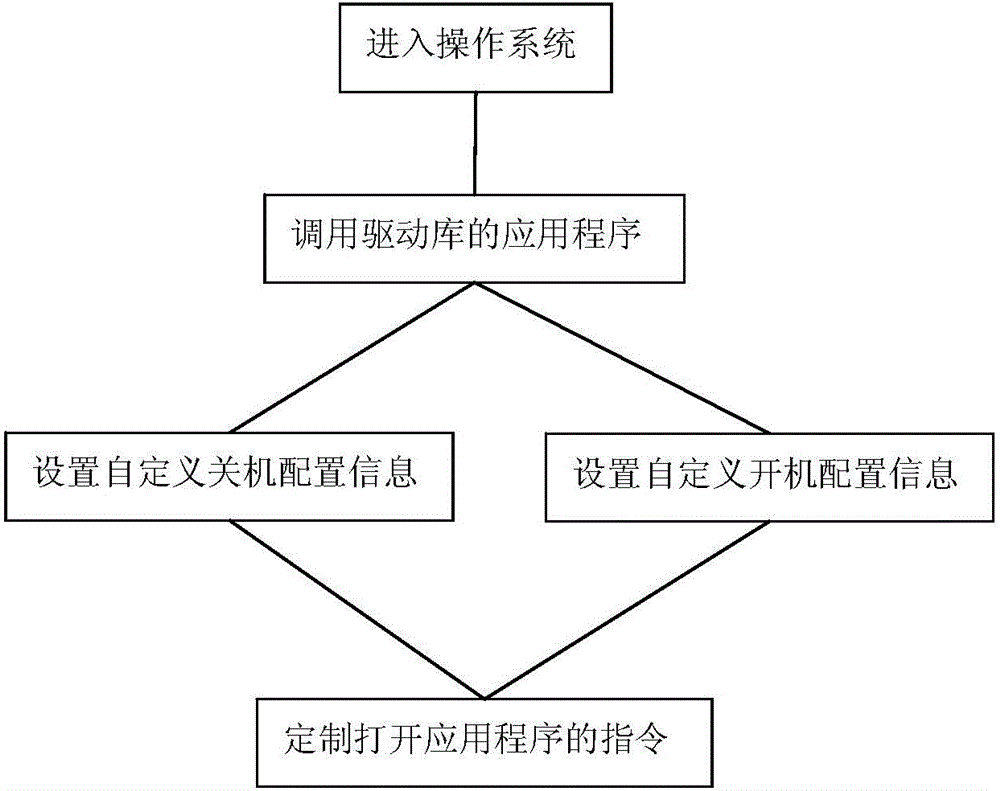

Method for turning on and turning off computer automatically based on UEFI BIOS

InactiveCN106293780AEasy to operateGood automatic intelligent controlProgram loading/initiatingBIOSComputer engineering

The invention provides a method for turning on and turning off a computer automatically based on UEFI BIOS. The method comprises the steps that (A) a system bottom-layer calling service is set; and (B) configuration information of an application program is set under an operation system. According to the invention, the system bottom-layer calling service is set by the UEFI BIOS, so that customized turning-on time can be directly set under the operation system, and thus customized turning-on can be achieved. Meanwhile, automatic turning-off can be achieved under the operation system through calling of the application program in a drive library and setting of customized turning-off configuration information of the application program. In addition, the turning-on and turning-off of the computer can be controlled better in a full-automatic and intelligent manner; power source consumption of companies or families can be reduced; and hardware consumption of the computer can be reduced, so that the computer can be protected.

Owner:SHENZHEN PRAFLY TECH

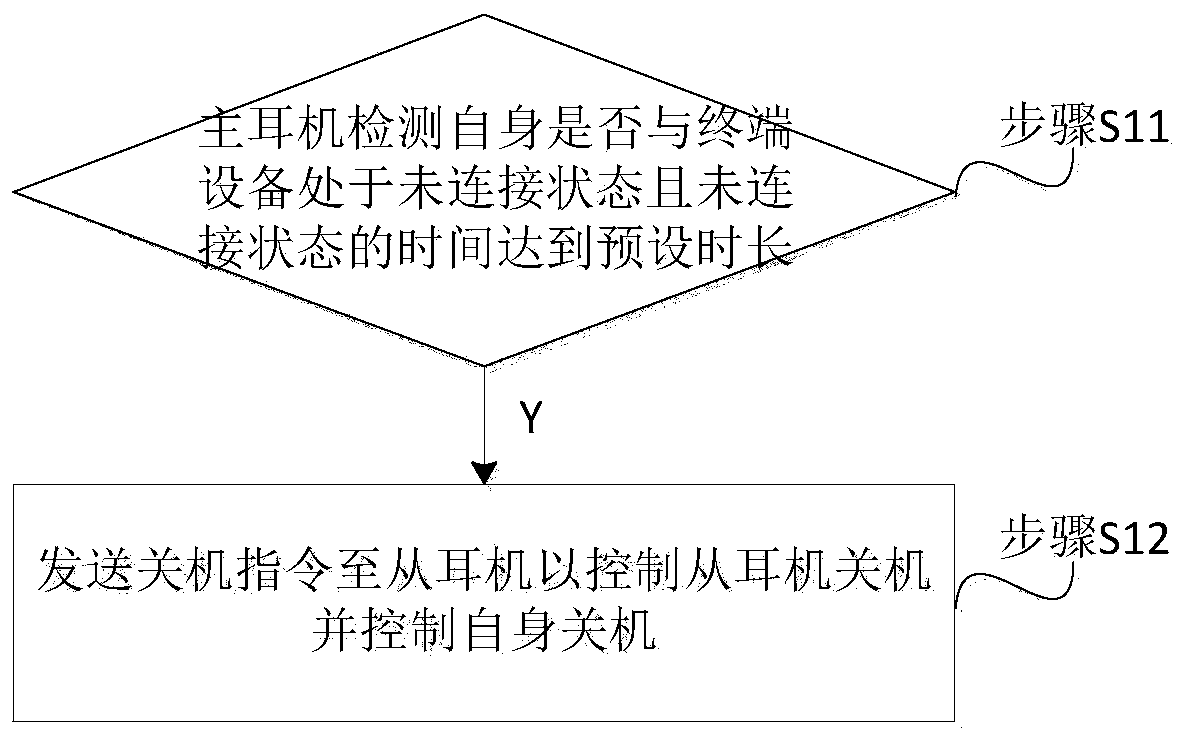

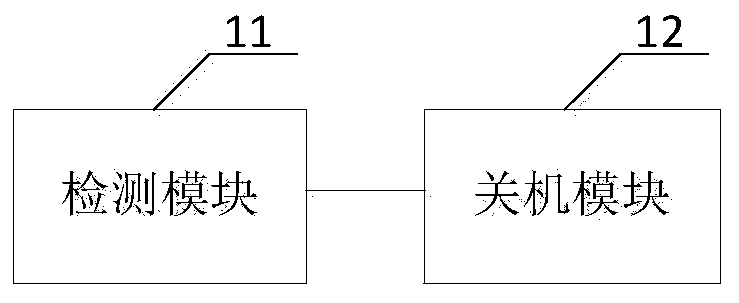

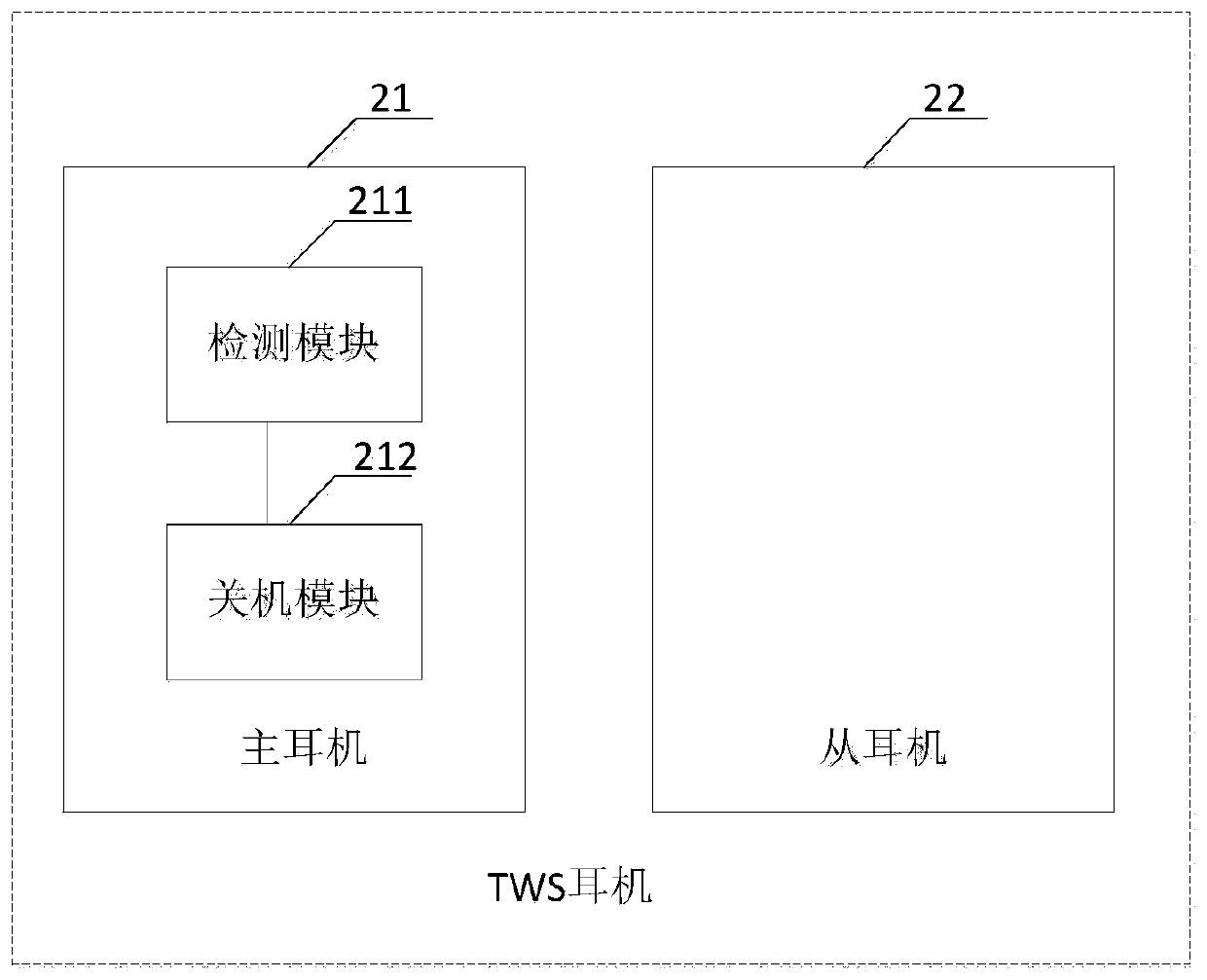

Control method and system of wireless earphone, and TWS earphone

InactiveCN110677767ARealize automatic shutdownSave powerEarpiece/earphone mechanical/electrical switchesControl systemTerminal equipment

The invention discloses a control method of a wireless earphone. A main earphone connected with the terminal equipment can detect whether the main earphone is not connected with the terminal equipmentor not; when the main earphone detects that the main earphone and the terminal equipment are in a disconnected state and the disconnected state reaches a preset duration, it is indicated that the wireless earphone cannot be used at the moment and in a future period of time; the main earphone controls the main earphone to be powered off and sends a power-off instruction to the slave earphone to control the slave earphone to be powered off. Finally, automatic shutdown of the master earphone and the slave earphone is realized, the wireless earphone is prevented from being always in a power-on state, the electric quantity of a battery in the wireless earphone is saved, convenience is brought to the next use of a user, on the basis, frequent power-on and power-off are also avoided, and the user experience is further improved. The invention also discloses a control system of the wireless earphone and the TWS earphone, which have the same beneficial effects as the control method of the wireless earphone.

Owner:GEER TECH CO LTD

Intelligent controller capable of realizing unmanned automatic turn off of air conditioner

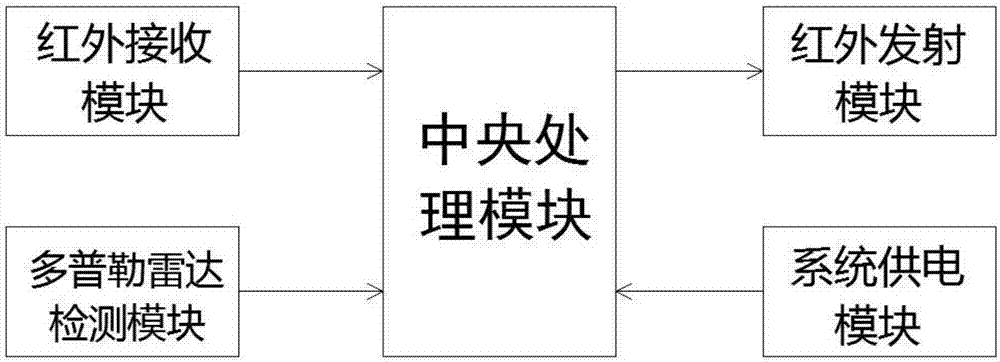

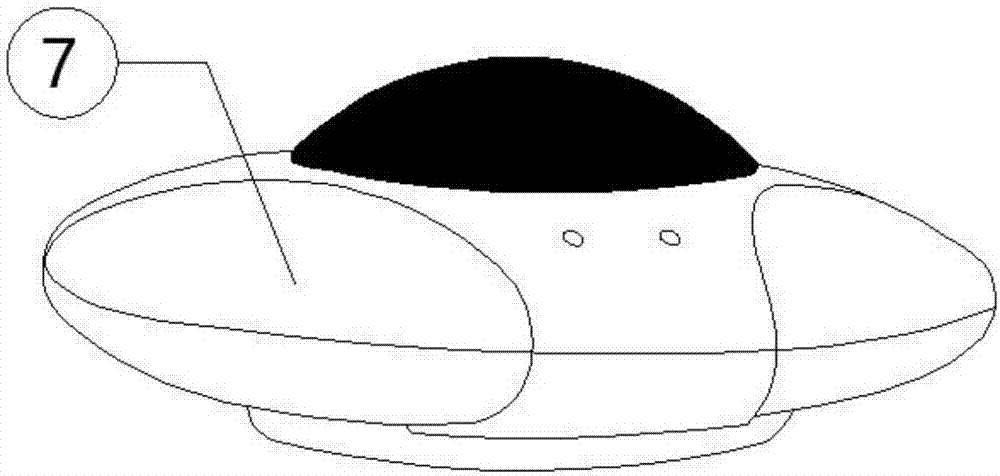

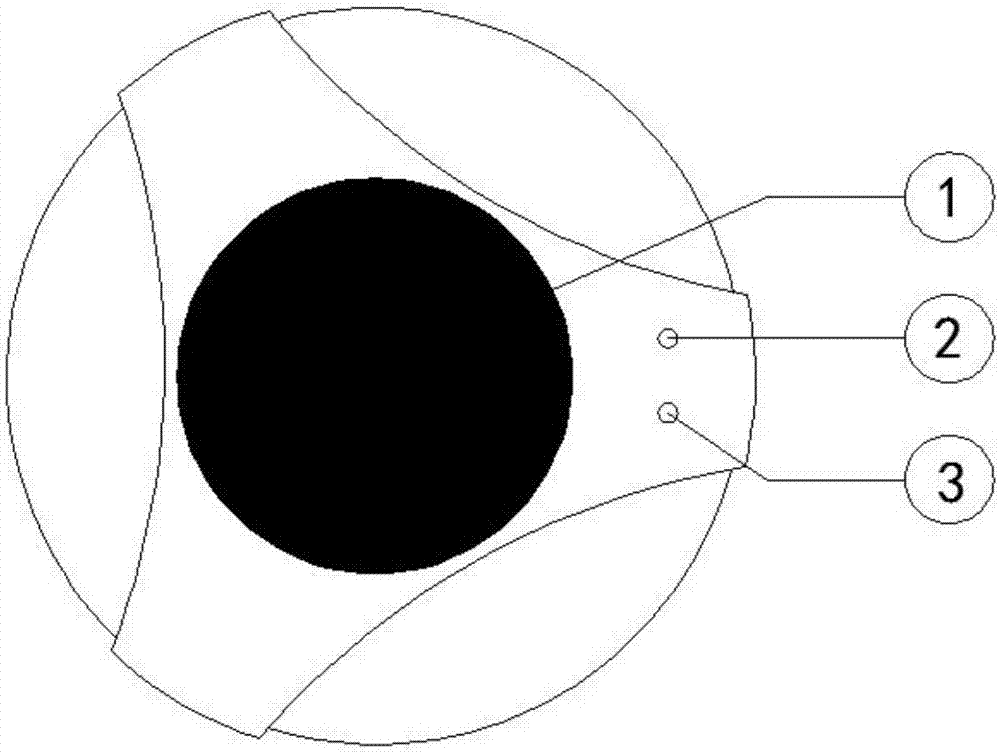

InactiveCN106989487AAchieve reliabilityGuarantee the safety of useMechanical apparatusSpace heating and ventilation safety systemsEngineeringRadar detection

The invention discloses an intelligent controller capable of realizing unmanned automatic turn off of an air conditioner. The intelligent controller comprises an infrared receiver module, a Doppler radar detection module and a central processing module, wherein the infrared receiver module, the Doppler radar detection module, the central processing module, an infrared transmitter module and a system power supply module are fixed in a housing; each of the infrared receiver module, the Doppler radar detection module, the infrared transmitter module and the system power supply module is connected with the central processing module through a respective connecting circuit. According to the intelligent controller capable of realizing unmanned automatic turn off of the air conditioner, the air conditioner can be automatically turned off in the situation that a user forget to turn off the air conditioner after leaving, so that not only energy conservation is achieved, but also the safety use of the air conditioner is ensured, and meanwhile a common air conditioner is endowed with the functions of an intelligent air conditioner.

Owner:淮南市科源佳华科技有限公司

Cabinet air conditioner with exhaust port sliding door

InactiveCN101220974ARealize automatic shutdownGuaranteed aestheticsLighting and heating apparatusAir conditioning systemsDrive wheel

Owner:GREE ELECTRIC APPLIANCES INC

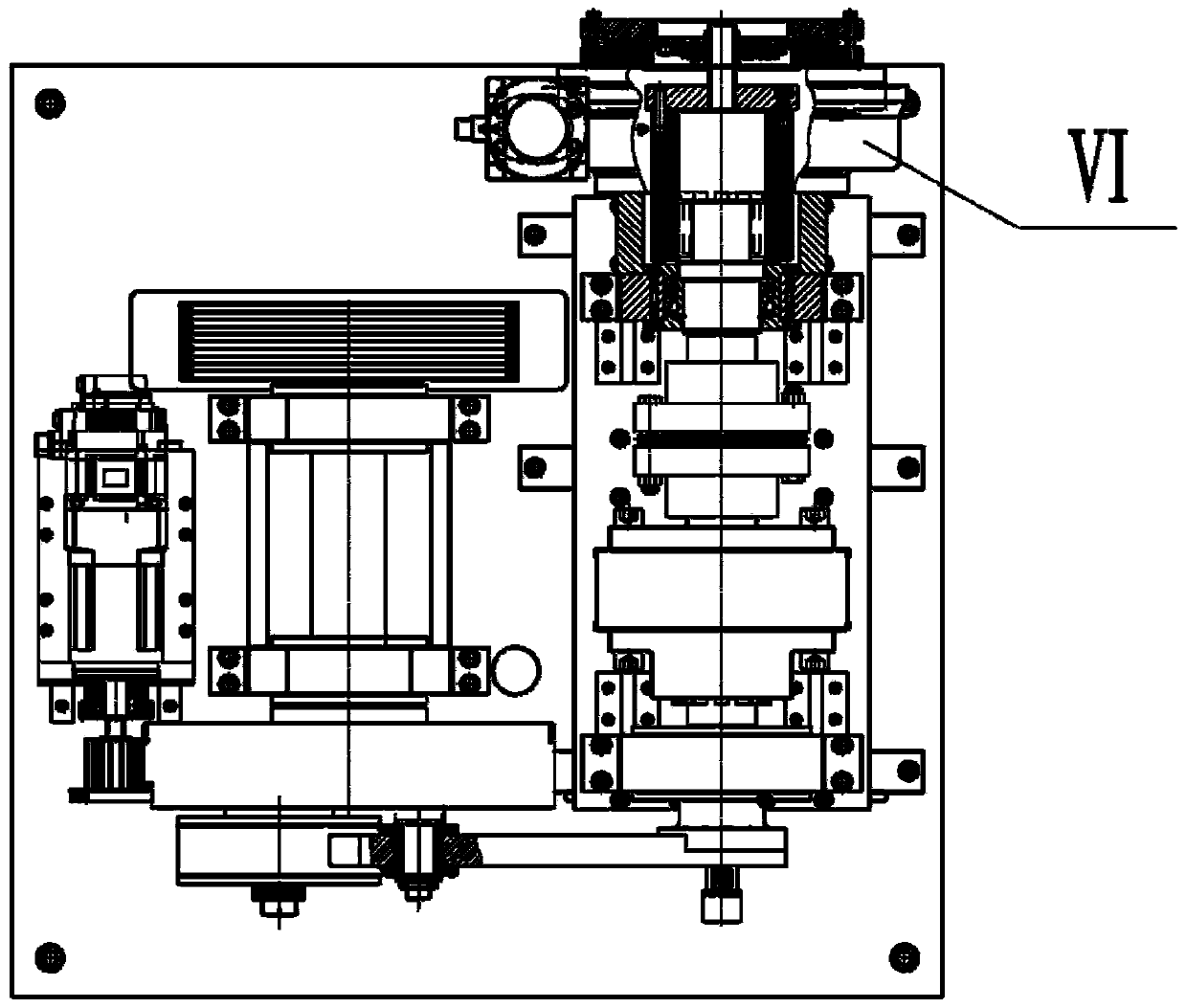

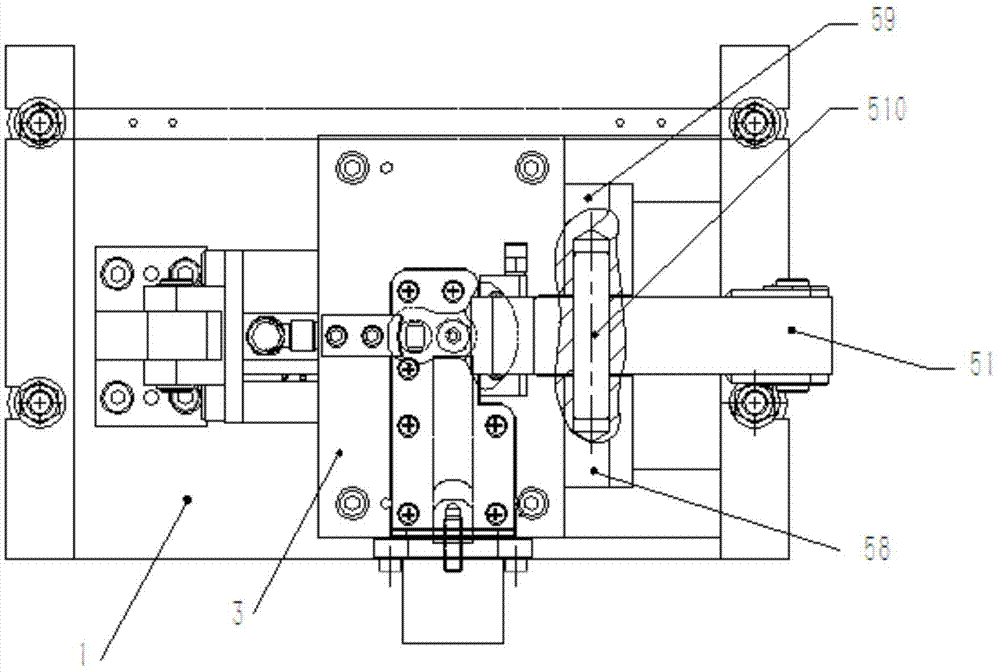

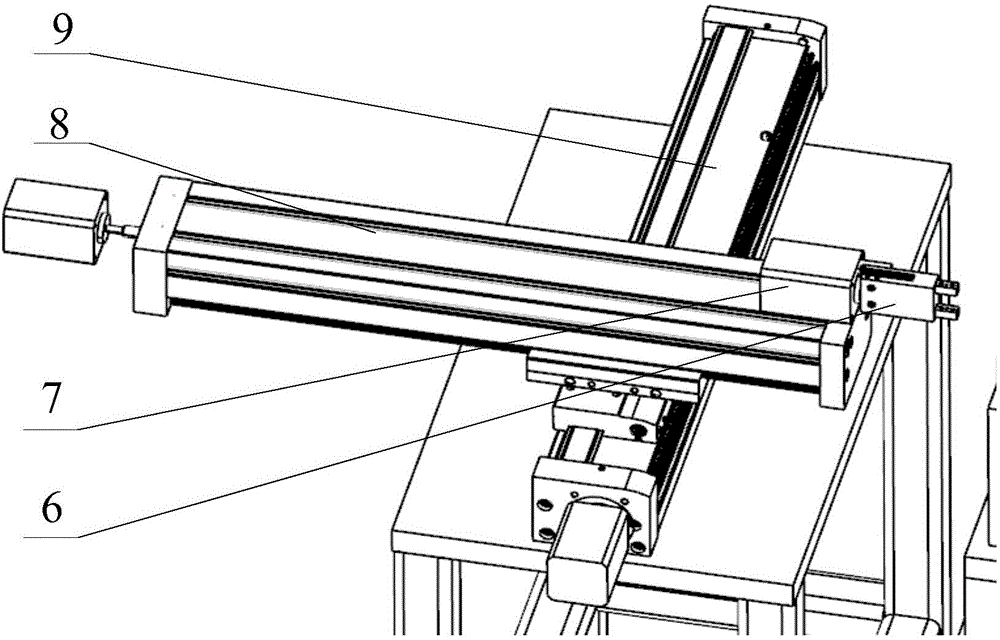

Full automatic tooling clamp for semi-crankshaft finish machining

ActiveCN104772637ARealize fully automatic unmanned processingRealize automatic shutdownMeasurement/indication equipmentsPositioning apparatusManipulatorCrankshaft

The invention discloses a full automatic tooling clamp for semi-crankshaft finish machining. The tooling clamp is characterized by comprising a base, two side plates, a cover plate, two locating blocks, a floating pressing mechanism, a locating pin and a radial pressing mechanism, wherein the bottom parts of the two side plates are fixedly welded on the base, the cover plate is fixedly connected with the top parts of the two side plates through screws, and an n shape is formed by the two side blocks and the cover plate; the top of the cover plate is transversely and fixedly provided with the two locking blocks, the top surfaces of the two locking blocks are located in a same horizontal plane, a locating pin mounting hole and a crankshaft journal mounting hole which vertically penetrate through the cover plate are formed between the two locating blocks of the cover plate and the locating pin is arranged in the locating pin mounting hole; the cover plate is longitudinally provided with the radial pressing mechanism, and the floating pressing mechanism is arranged above the locating block. The full automatic unmanned processing can be realized; furthermore, each link can be detected, including the feeding and discharging in-place detection of a manipulator, work-piece clamping and loosening detection, work-piece clamping in-place request processing or discharging detection and the like.

Owner:JINAN FIRST MACHINE TOOL GROUP

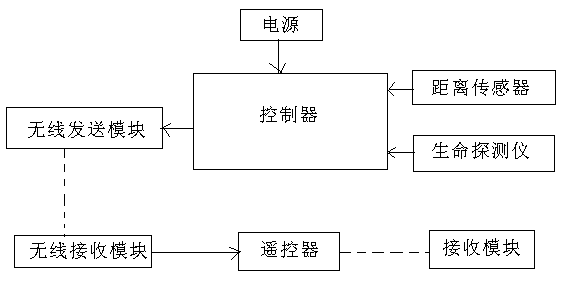

Shutdown device

InactiveCN103002237AReduce harmRealize automatic shutdownTelevision system detailsNon-electrical signal transmission systemsControl signalEngineering

The invention discloses a shutdown device, and belongs to the field of shutdown devices. The shutdown device comprises a receiving module, a power source, a controller, a life detection instrument, a range sensor, a wireless transmitting module, a wireless receiving module and a remote controller. The receiving module used for receiving control signals is arranged on a set-top box of a television, the power source is connected with the controller, the controller is connected with the life detection instrument, the range sensor and the wireless transmitting module, and the wireless receiving module is connected with the remote controller. The shutdown device has the advantages that whether a person sleeps or not is detected, so that the remote controller is controlled and transmits corresponding shutdown signals to the receiving module, the television can be shut down automatically, electric energy is saved, and harm to a human body is reduced.

Owner:XUZHOU DONGFANG TRANSMISSION MACHINERY

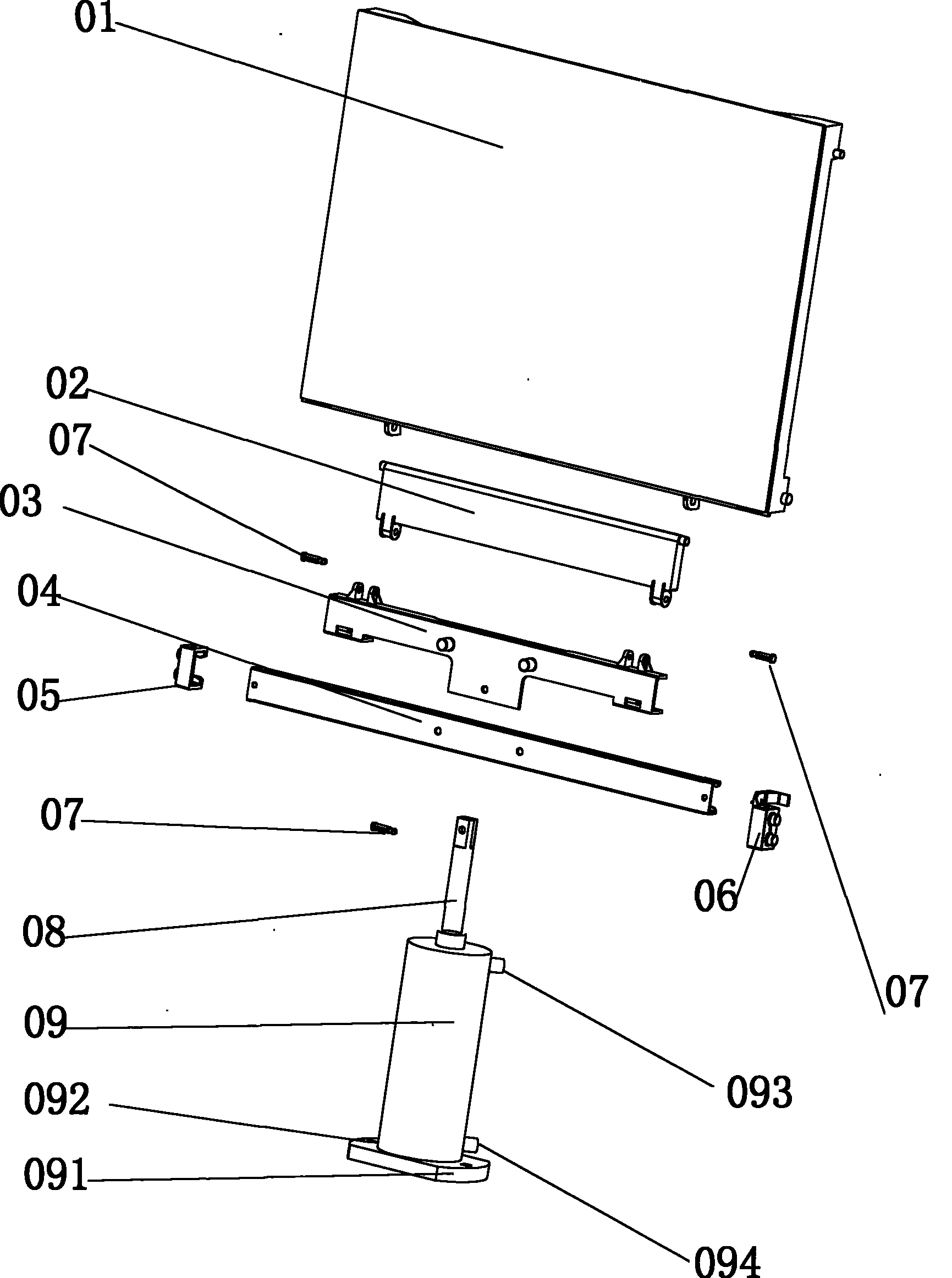

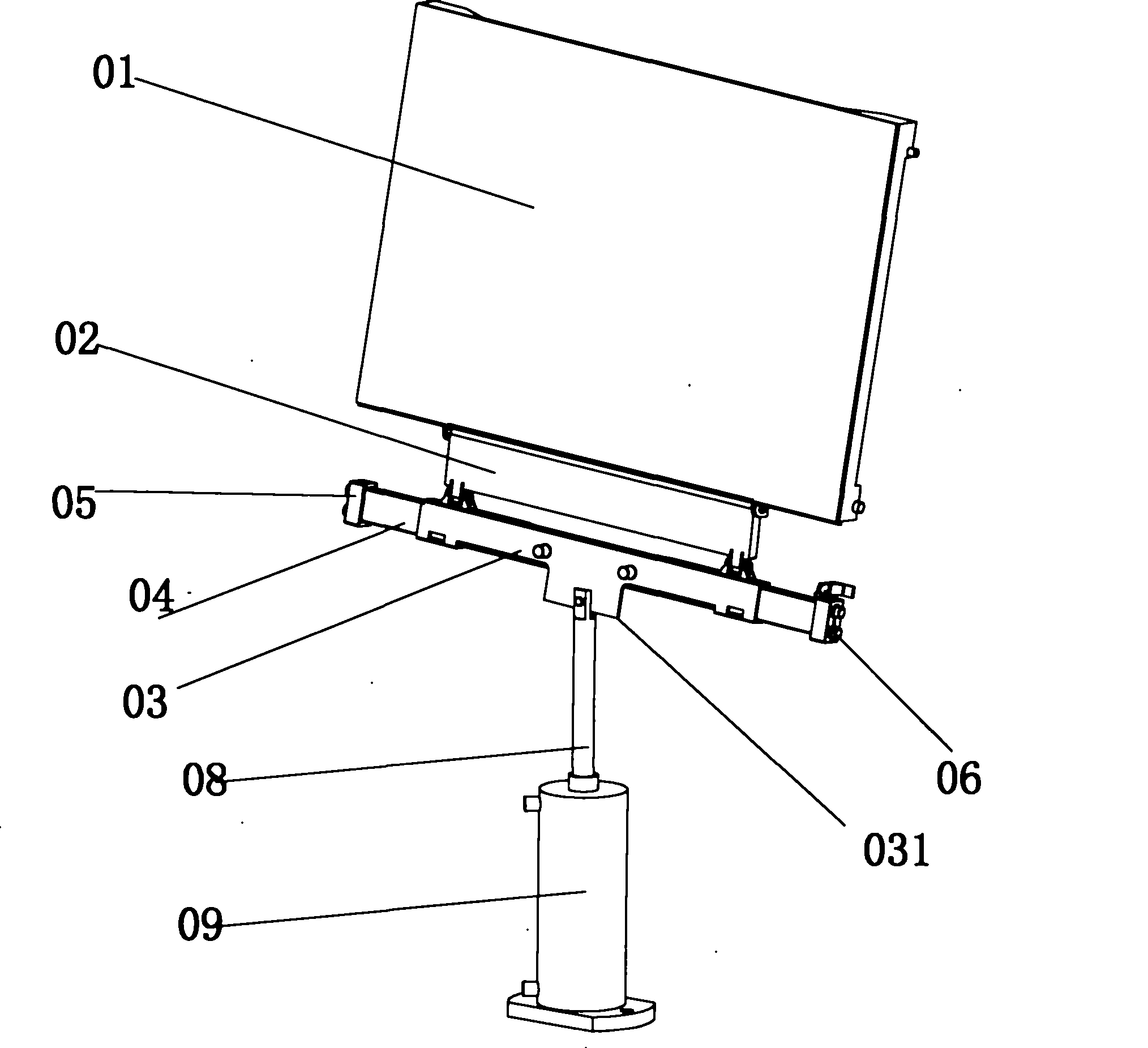

Full magnet-pasting machine

InactiveCN101306737AIncrease the firmness of the fitNo skewLabelling deformable materialsLabelling machinesPower unitMagnet

The invention relates to a magnet plastering device, particularly to a full automatic magnet plastering device, which comprises a workbench, and a front bracket, a main bracket, a rear bracket, a control board and a power unit arranged on the workbench. A magnetic strip wheel and a strip winding wheel are installed on the upper part of the main bracket; a guiding wheel, a rotating shaft, a press roller and a guide wheel are sequentially installed on the lower part of the main bracket from the front side to the rear side; a heating barrel is installed on the rotating shaft, and a heater is installed on the main bracket and connected with an induced draft fan; a stopper is installed on the front bracket, a first front delivery roller and a second front delivery roller are installed on the workbench below the front bracket; a first rear delivery roller and a second rear delivery roller are installed on the rear bracket; and a material receiving tank is arranged on the rear side of the rear bracket and a sensor is installed on the front side thereof. The inventive magnet plastering device has the advantages of continuous magnet plastering, remarkably improved production efficiency, accurate feeding, automatic feeding and receiving, reduced labor intensity and so on.

Owner:东港股份有限公司

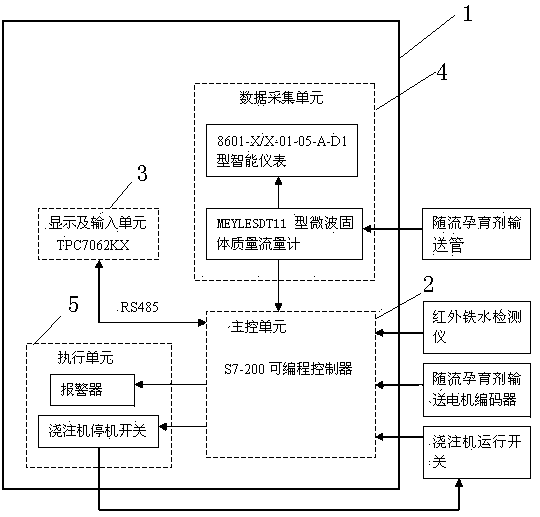

Casting pouring metal-stream inoculation automatic monitoring system

The invention relates to a casting pouring metal-stream inoculation automatic monitoring system which comprises a system control cabinet, a master control unit, a display and input unit, a data collection unit and an execution unit. The display and input unit is connected with the master control unit through a signal line. The data collection unit comprises an intelligent instrument and a mass flowmeter which are in line connection. The mass flowmeter is mounted on a conveying pipe of a metal-stream inoculation agent. The master control unit is connected with the mass flowmeter. The executionunit comprises a pouring machine shutdown switch and an alarm. The pouring machine shutdown switch and the alarm are connected with the master control unit. The master control unit is further connected with a pouring machine operation switch on a pouring machine, an infrared molten iron detector and a metal-stream inoculation agent conveying motor encoder. The pouring machine shutdown switch and the pouring machine operation switch are in line connection. In the pouring process, the metal-stream inoculation agent is added timely, continuously and evenly, and therefore it is guaranteed that themetal-stream inoculation effect is stable, the performance of a casting gold phase and materials is stable, and defective products are reduced.

Owner:JILIN SHIBAO MACHINERY MANUFACTURING CO LTD

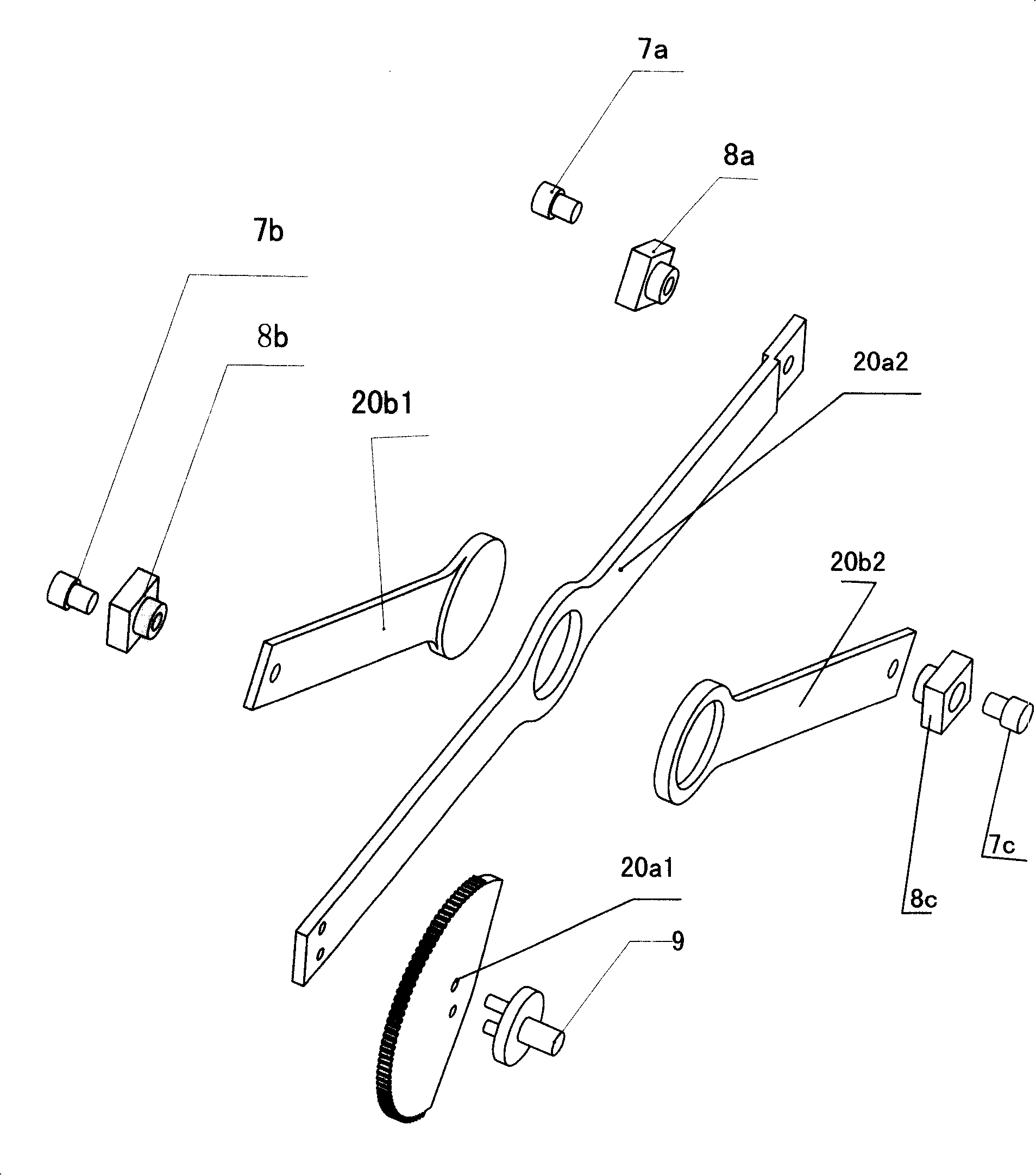

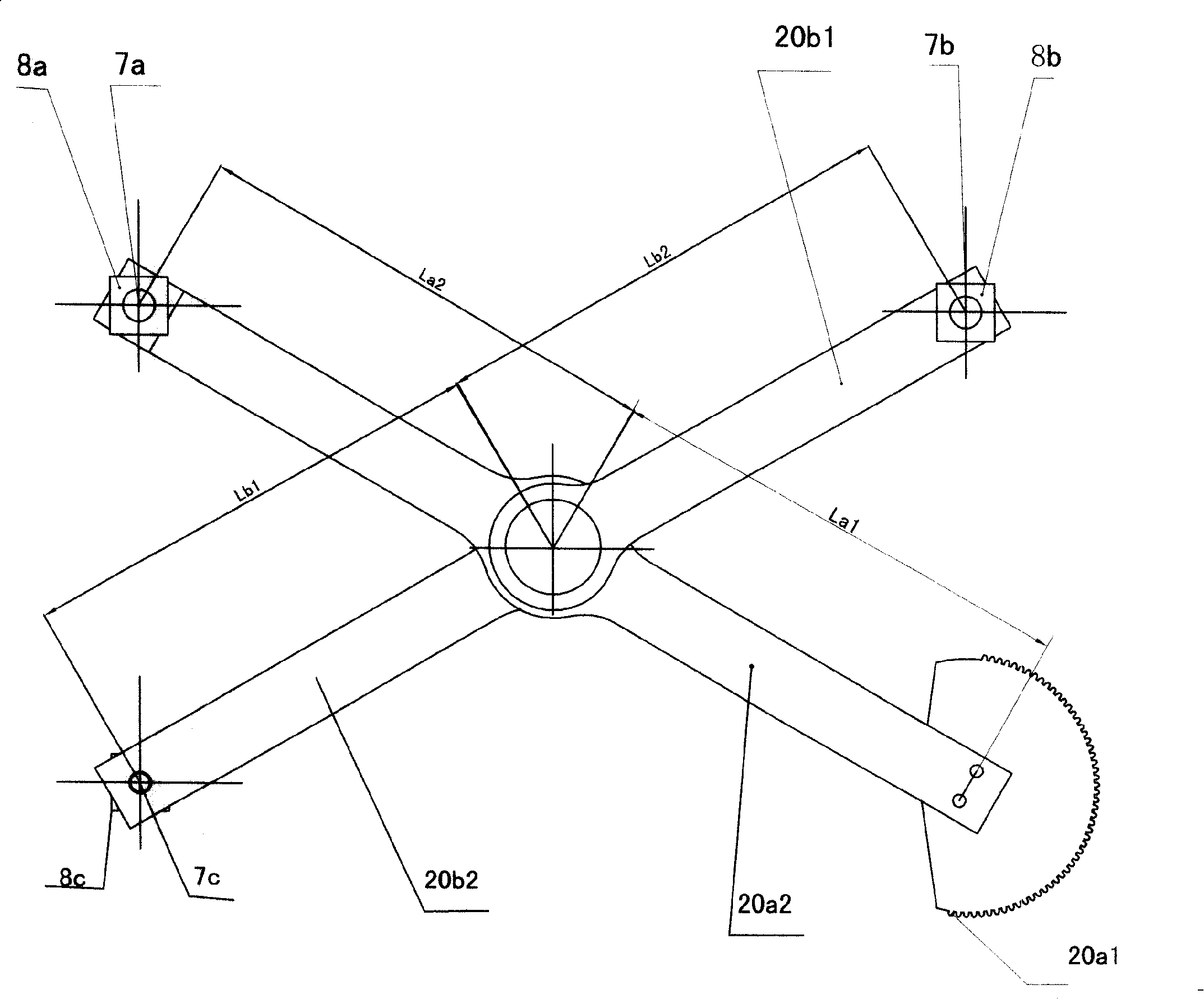

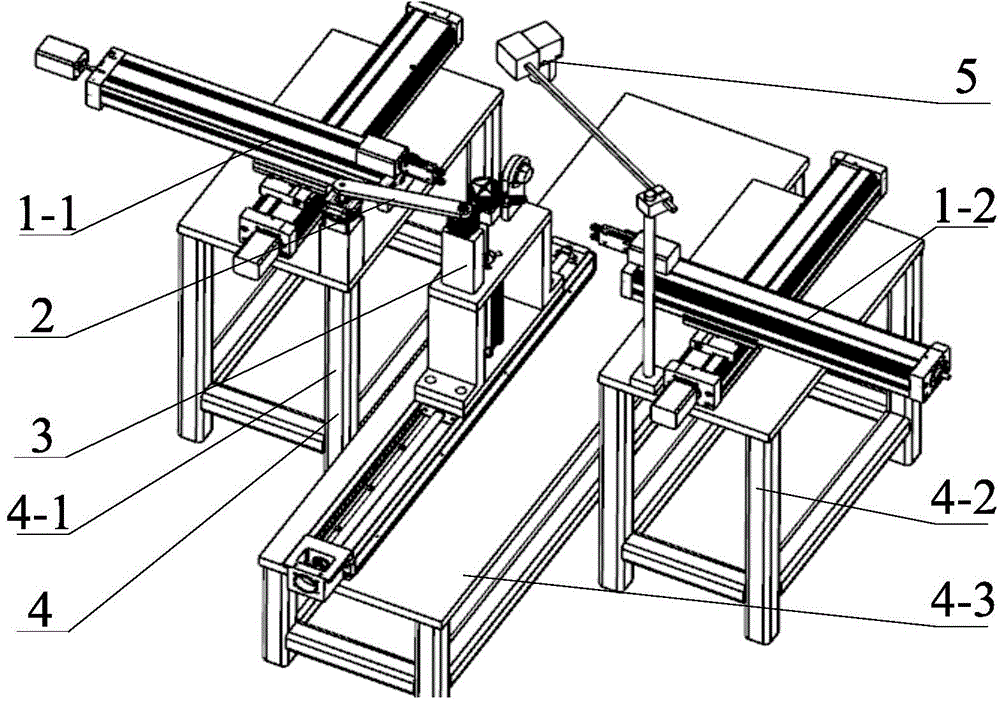

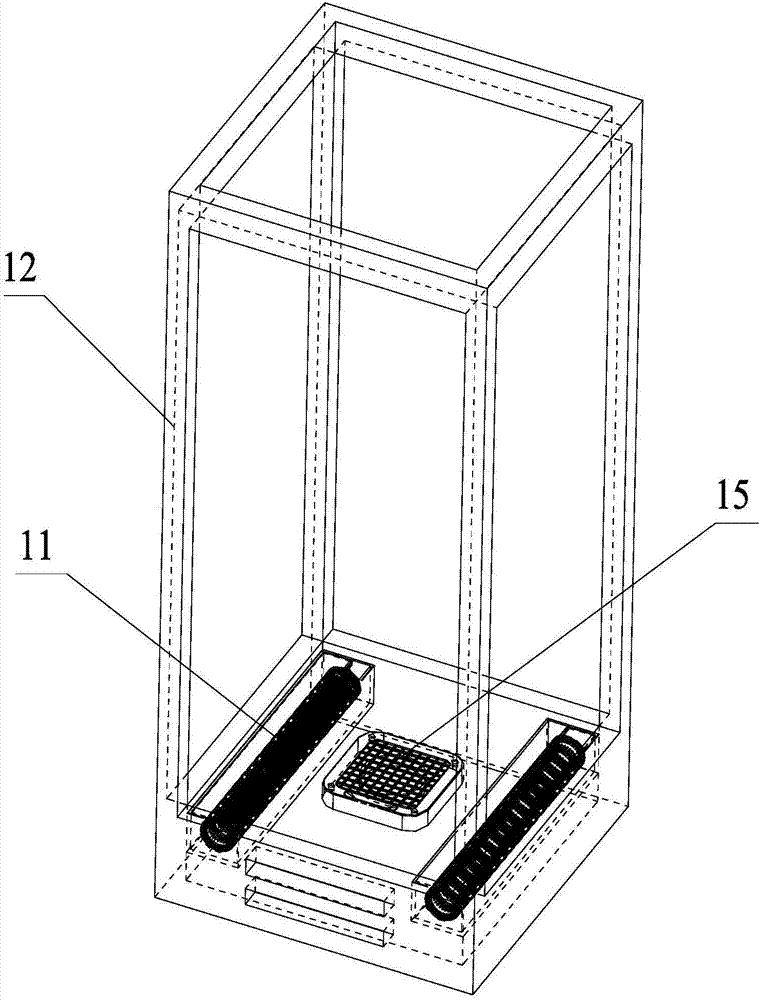

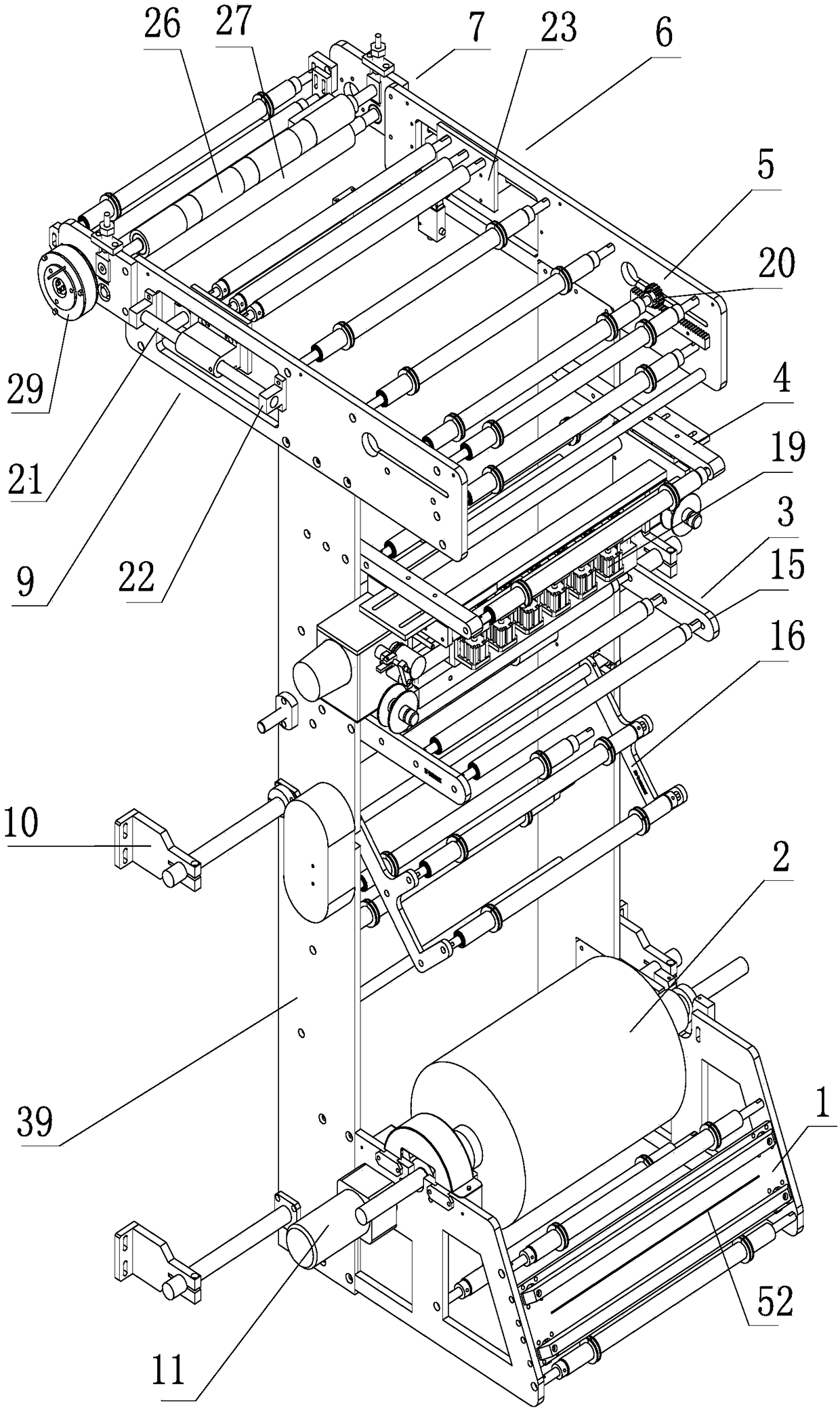

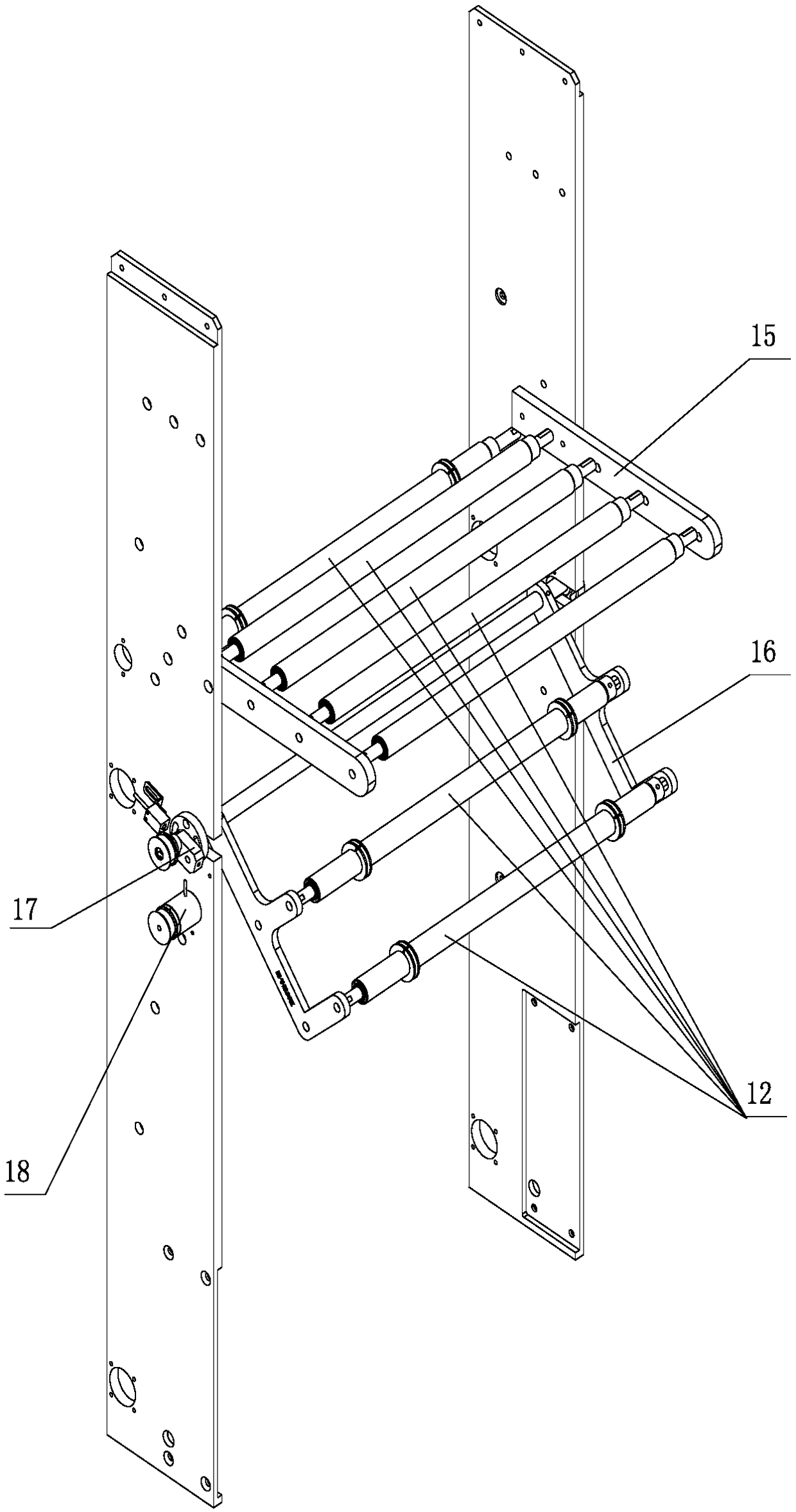

Automatic adhesive tape encapsulating mechanism

ActiveCN104828309ARealize multi-turn packageWork lessWrapper twisting/gatheringVisual inspectionEngineering

The invention discloses an automatic adhesive tape encapsulating mechanism. The automatic adhesive tape encapsulating mechanism comprises a first encapsulating manipulator, a second encapsulating manipulator, a finished product manipulator, an encapsulating device, a frame body and a robot visual inspection system, wherein the first encapsulating manipulator is arranged on a first encapsulating manipulator frame body; the second encapsulating manipulator is arranged on a second encapsulating manipulator frame body; the encapsulating device is arranged on an encapsulating device frame body; the finished product manipulator is arranged on the frame body; the first encapsulating manipulator and the second encapsulating manipulator are of the same structure and are symmetrical about the encapsulating device; the robot visual inspection system is fixedly connected with a bracket and is positioned above the encapsulating device. The invention provides the automatic adhesive tape encapsulating mechanism, which is simple and compact, and is suitable for circumferentially winding a small product; the automatic adhesive tape encapsulating mechanism is higher in automation degree, works quickly and acts accurately; the work efficiency can be greatly improved; the error rate can be greatly reduced.

Owner:JIANGSU RELAX AUTOMATION TECH CO LTD

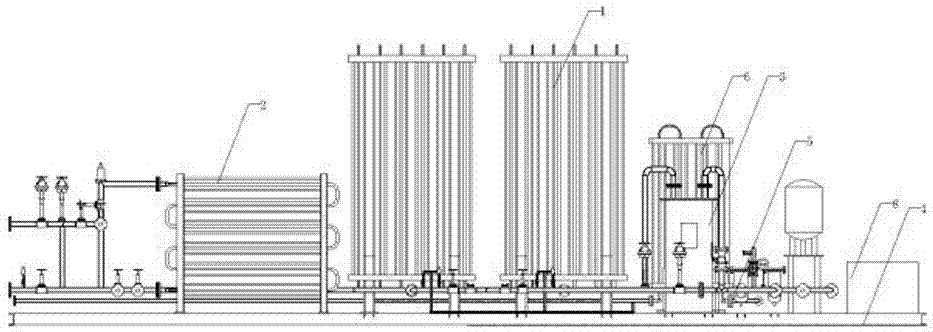

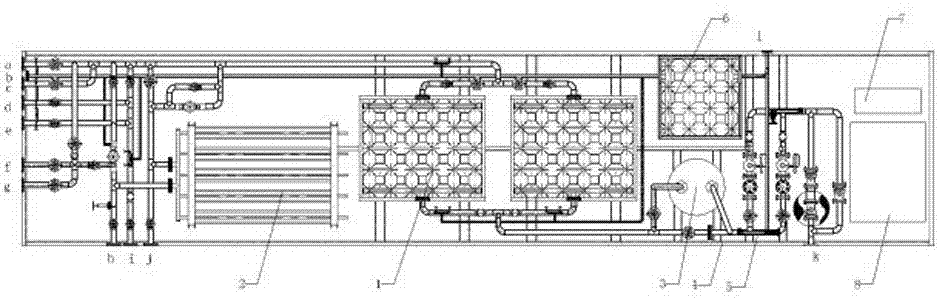

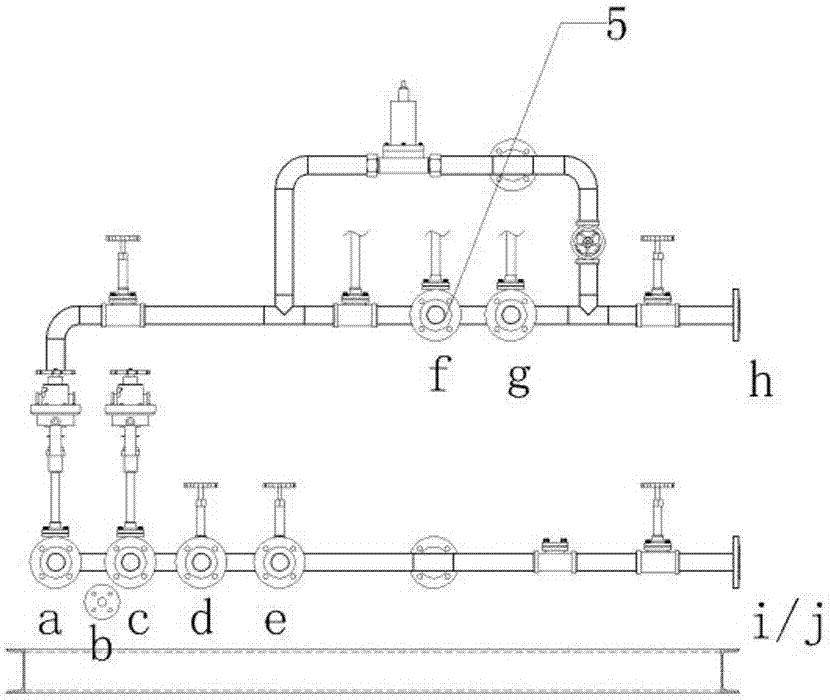

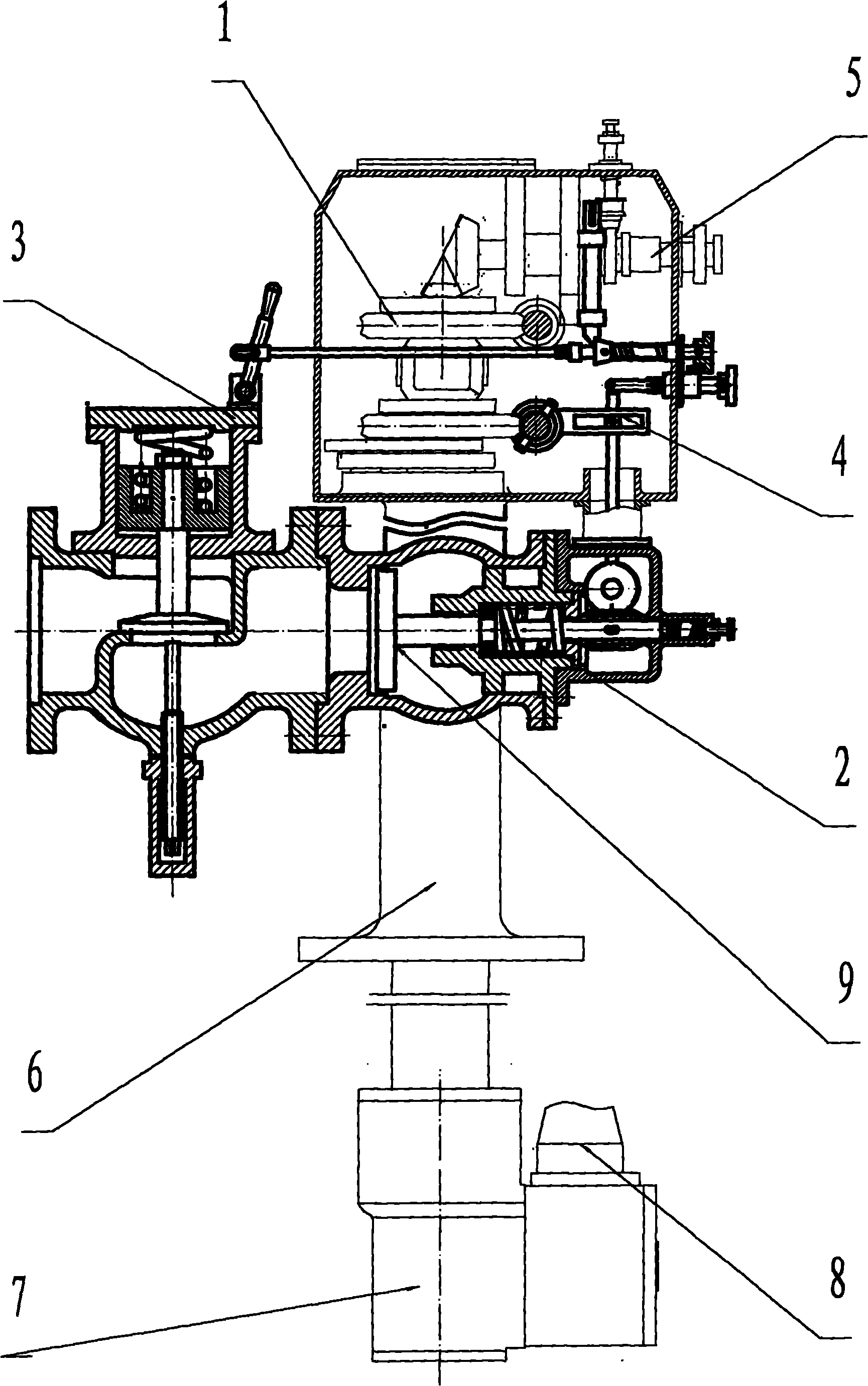

Automatically controlled gasification pressure regulator

InactiveCN107477356ACompact structureLow manufacturing costContainer filling methodsPipeline systemsAutomatic controlThermometer

An automatically controlled gasification pressure regulator comprises a framework base 4, and a supercharger 2, a first carburetor 1, a water-bath heater 3, a second carburetor 6, an air compressor 8 and a control cabinet 7 are sequentially and horizontally arranged on the upper portion of the framework base 4 in the length direction; the inlet end of an inlet of each carburetor is provided with a pneumatic emergency cut-off valve; a bypass and an inlet of the water-bath heater are provided with pneumatic emergency cut-off valves; the outlet end of each carburetor is provided with a temperature transmitter and a thermometer; an outlet of the water-bath heater is provided with a pressure transmitter, a pressure gauge and a temperature transmitter; an unloading supercharger and a storage tank supercharger are integrally arranged; the pneumatic emergency cut-off valves, the temperature transmitters and the pressure transmitter are connected with the control cabinet 7; and the control cabinet 7 is further connected with a gas leakage alarm instrument, a camera and a communication module. The unattended gasification pressure regulator is achieved, and real-time monitoring of the gasification pressure regulator can be achieved remotely.

Owner:山东新兴重工科技发展有限公司

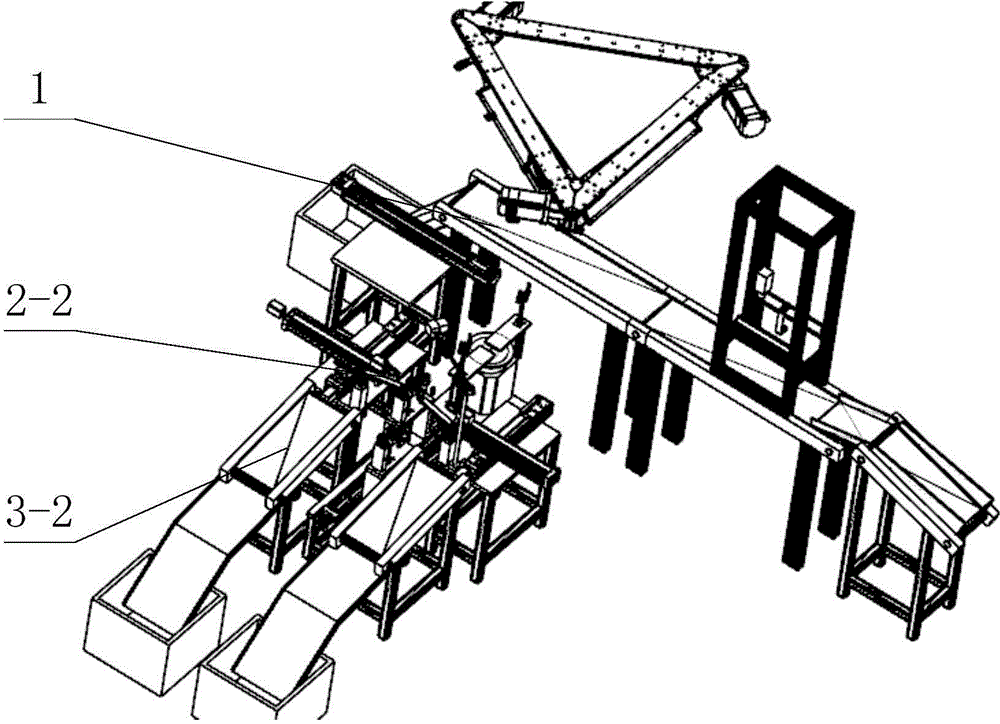

Continuous automatic adhesive tape packaging mechanism

ActiveCN104890948ARealize multi-turn packageWork lessWrapper twisting/gatheringEngineeringManipulator

The invention discloses a continuous automatic adhesive tape packaging mechanism. The continuous automatic adhesive tape packaging mechanism comprises two packaging mechanical arms, two finished product mechanical arms, two packaging devices, frame bodies and a robot vision detecting system. The first packaging mechanical arm and the first finished product mechanical arm are arranged on the first packaging mechanical arm frame body, and the second packaging mechanical arm and the second finished product mechanical arm are arranged on the second packaging mechanical arm frame body; the two packaging devices of the same structure are arranged on the packaging device frame body in parallel and are symmetric about the packaging device frame body; and the robot vision detecting system is fixedly connected to a support and are located above the packaging devices. The continuous automatic adhesive tape packaging mechanism is simple, compact and suitable for peripheral winding of small products, and is high in automation degree, rapid in working, accurate in motion and capable of greatly improving the working efficiency, and greatly reduces the error rate; and meanwhile, the aim that when adhesive tape is manually replaced, the mechanism can continuously work is achieved.

Owner:JIANGSU RELAX AUTOMATION TECH CO LTD

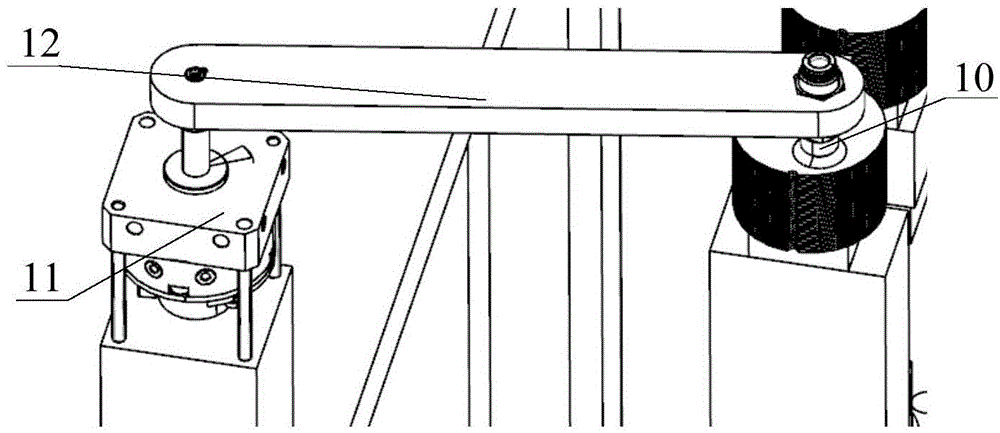

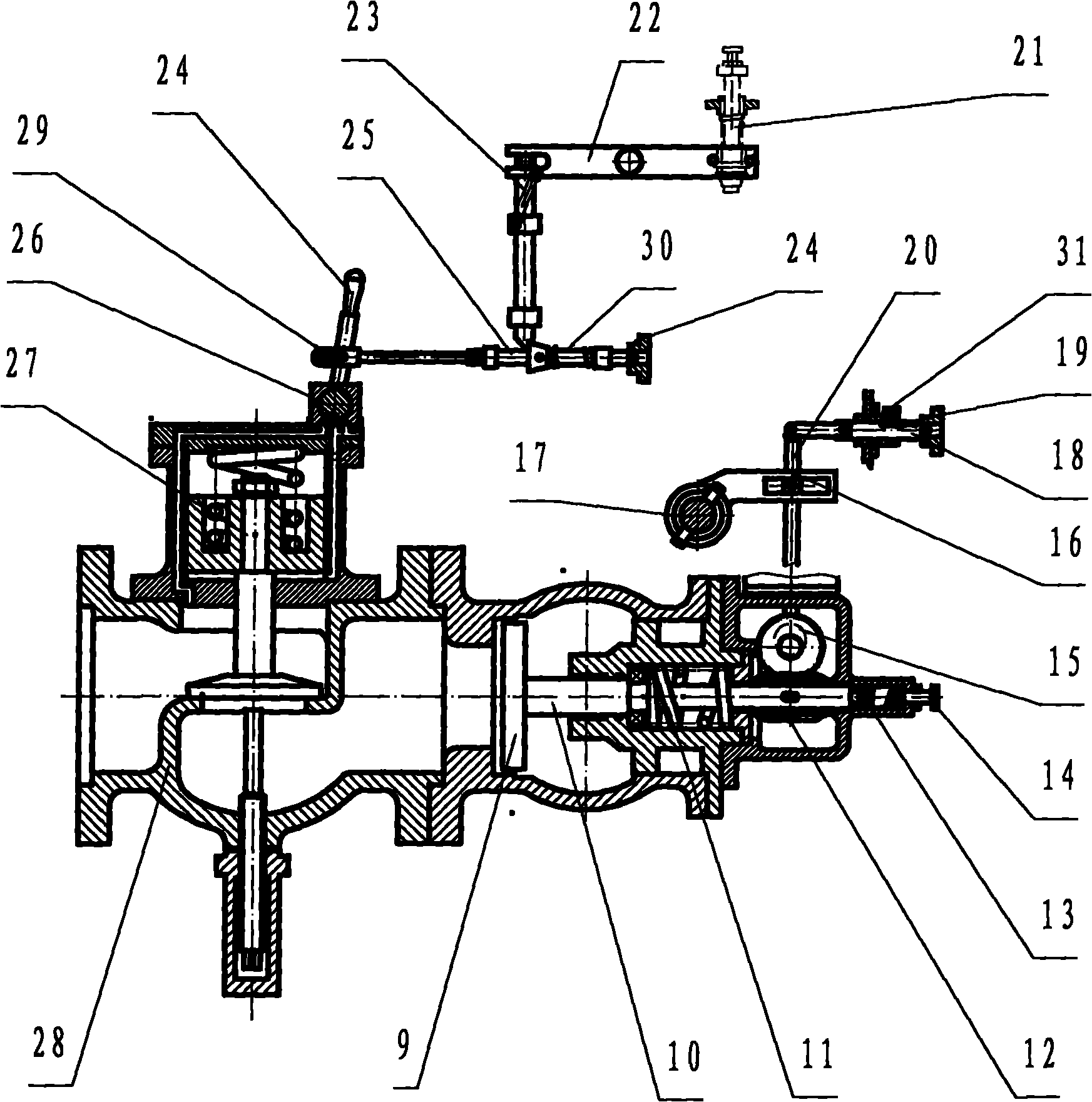

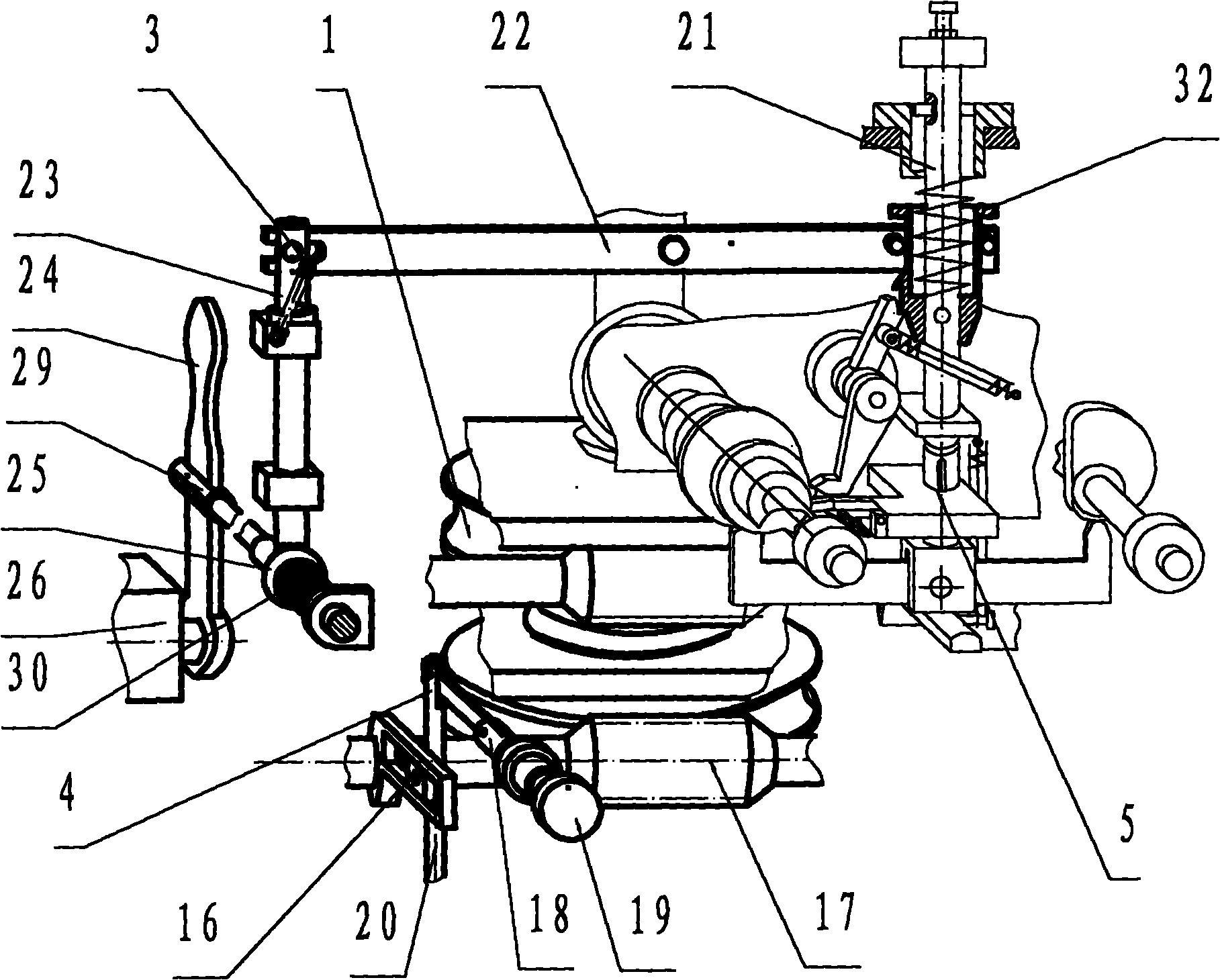

Impeller drive control mechanism of stationary crude oil tank washing machine

The invention discloses an impeller drive control mechanism of a stationary crude oil tank washing machine, comprising a main transmission part arranged in the main body, an impeller drive part, an impeller drive start-stop control part and a nozzle horizontal rotation speed adjustment mechanism connected with the impeller drive part. The impeller drive part comprises an impeller, a hydraulic control stop valve at the front end of the impeller, a transmission shaft connected at the rear end of the impeller, a main spring sleeved on the transmission shaft, an auxiliary spring and a worm. The warm is connected with the nozzle horizontal rotation speed adjustment mechanism via a worm gear engaged with the worm. The nozzle horizontal rotation speed adjustment mechanism comprises an eccentric gear and a transmission rod arranged on the worm gear. The lower end of the transmission rod is connected with the eccentric gear on the worm gear. A speed adjustment rod and a speed adjustment swing rod are connected at the top of the transmission rod. A slide block is arranged on the transmission rod. The slide block is connected with the sliding way of the speed adjustment swing rod. The speed adjustment swing rod is connected with the main transmission worm rod. The impeller drive start-stop control part comprises a control valve connected with the hydraulic control stop valve, a handle connected with the control valve, a manual control rod connected with the handle via a connection rod as well as an upright rod, a lever, a vertical control pull rod and a stop block on the vertical control pull rod which are connected with each other. The mechanism can automatically adjust the axial position of the impeller, and the nozzle horizontal rotation speed is adjustable. The mechanism can realize the single machine automatic shutdown by means of the mechanism.

Owner:HAIYING ENTERPRISE GROUP

Clothes dryer and control method thereof

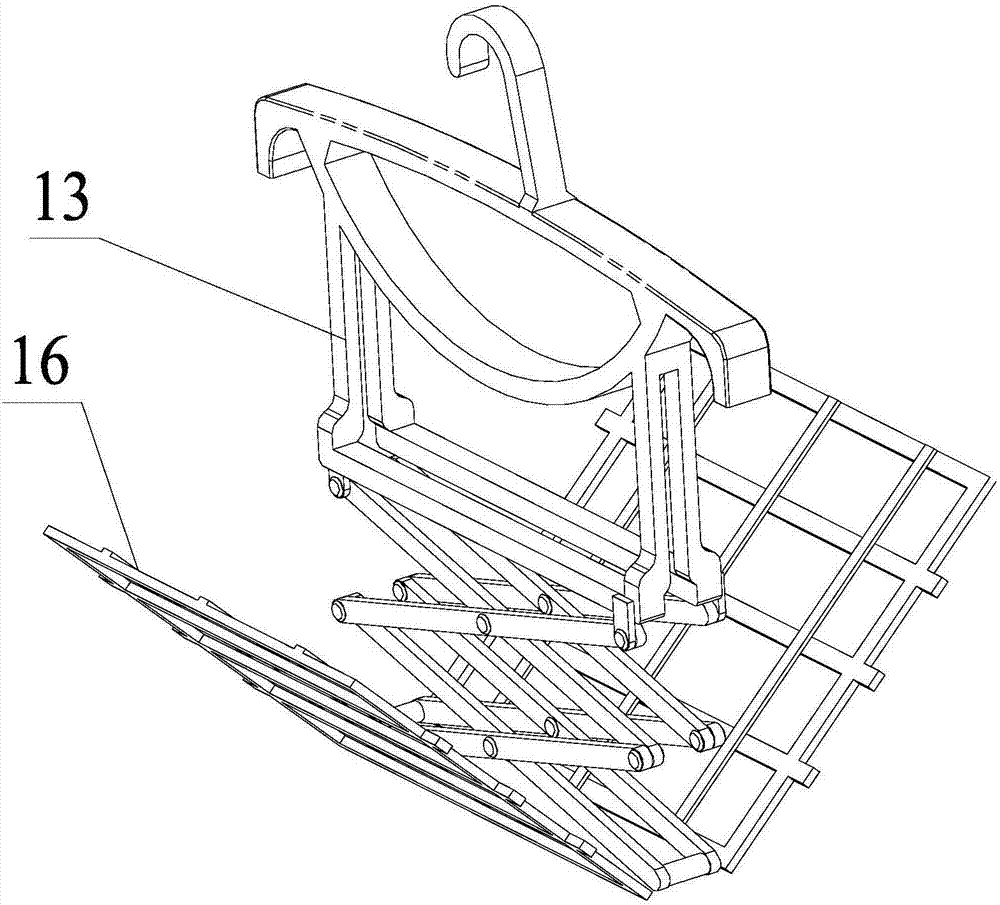

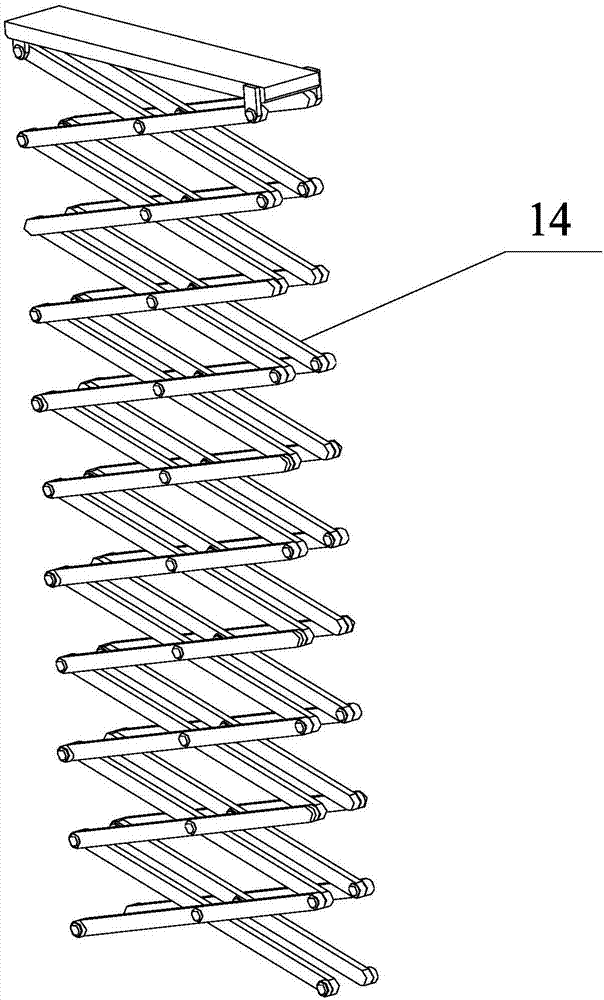

InactiveCN107385831AIncrease temperatureEasy dischargeTextiles and paperLaundry driersEngineeringClothes hanger

The invention discloses a clothes dryer. The clothes dryer comprises a chamber, a clothes hanger in the chamber, a hot air unit, an air inlet, an air outlet, a control device, a temperature detection device and a control device. The chamber is provided with a hermetical clothes drying space and an openable door; the hot air unit is arranged at the bottom of the chamber and used for providing hot air for the clothes drying space; the chamber is provided with the air inlet and the air outlet, and the control device controls openness of the air inlet and the air outlet; the temperature detection device is used for detecting internal and external temperatures of the chamber and is in communication connection with the control device; the control device controls openness of the air inlet and the air outlet according to the internal and external temperatures of the chamber. Therefore, the clothes dryer is capable of improving drying efficiency.

Owner:嘉兴衣而乐电器有限公司

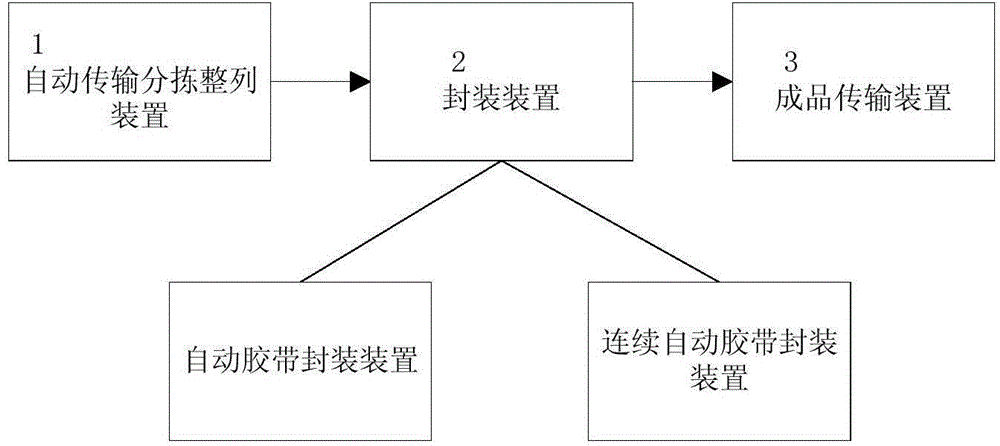

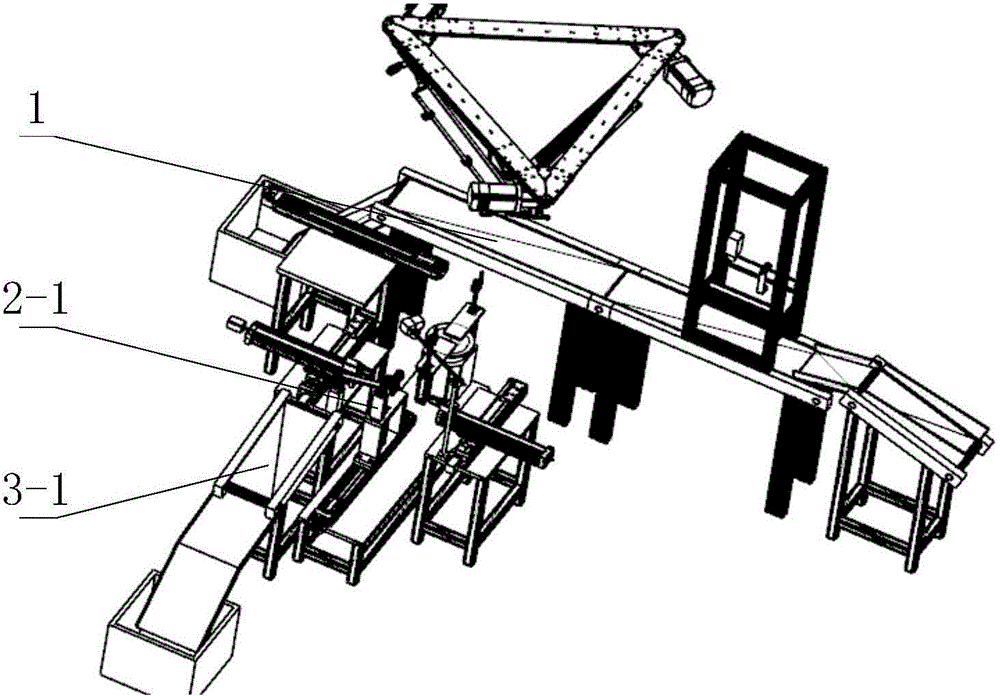

Automatic adhesive tape encapsulating mechanism

ActiveCN104828272AImprove workImprove work efficiencyBinding material applicationPackaging automatic controlMechanical engineeringAdhesive belt

The invention discloses an automatic adhesive tape encapsulating mechanism. The automatic adhesive tape encapsulating mechanism comprises an automatic transmitting, sorting and arraying device, an encapsulating device and a finished product transmitting device; the encapsulating device is positioned between the automatic transmitting, sorting and arraying device and the finished product transmitting device, wherein the automatic transmitting, sorting and arraying device is used for transmitting and sorting products to be encapsulated, arraying the sorted products to be encapsulated and transmitting the arrayed products to be encapsulated to the input end of the encapsulating device; the encapsulating device is used for encapsulating the products to be encapsulated; the finished product transmitting device is used for transmitting encapsulated finished products. The invention provides the automatic adhesive tape encapsulating mechanism, which is high in automation degree and is suitable for circumferentially winding small products. The automatic adhesive tape encapsulating mechanism is high in automation degree, works quickly and acts accurately; the work efficiency can be greatly improved; the error rate can be greatly reduced; the products can be subjected to primary quality screening. The condition that the mechanism can work continuously when an adhesive tape is replaced manually is realized.

Owner:JIANGSU RELAX AUTOMATION TECH CO LTD

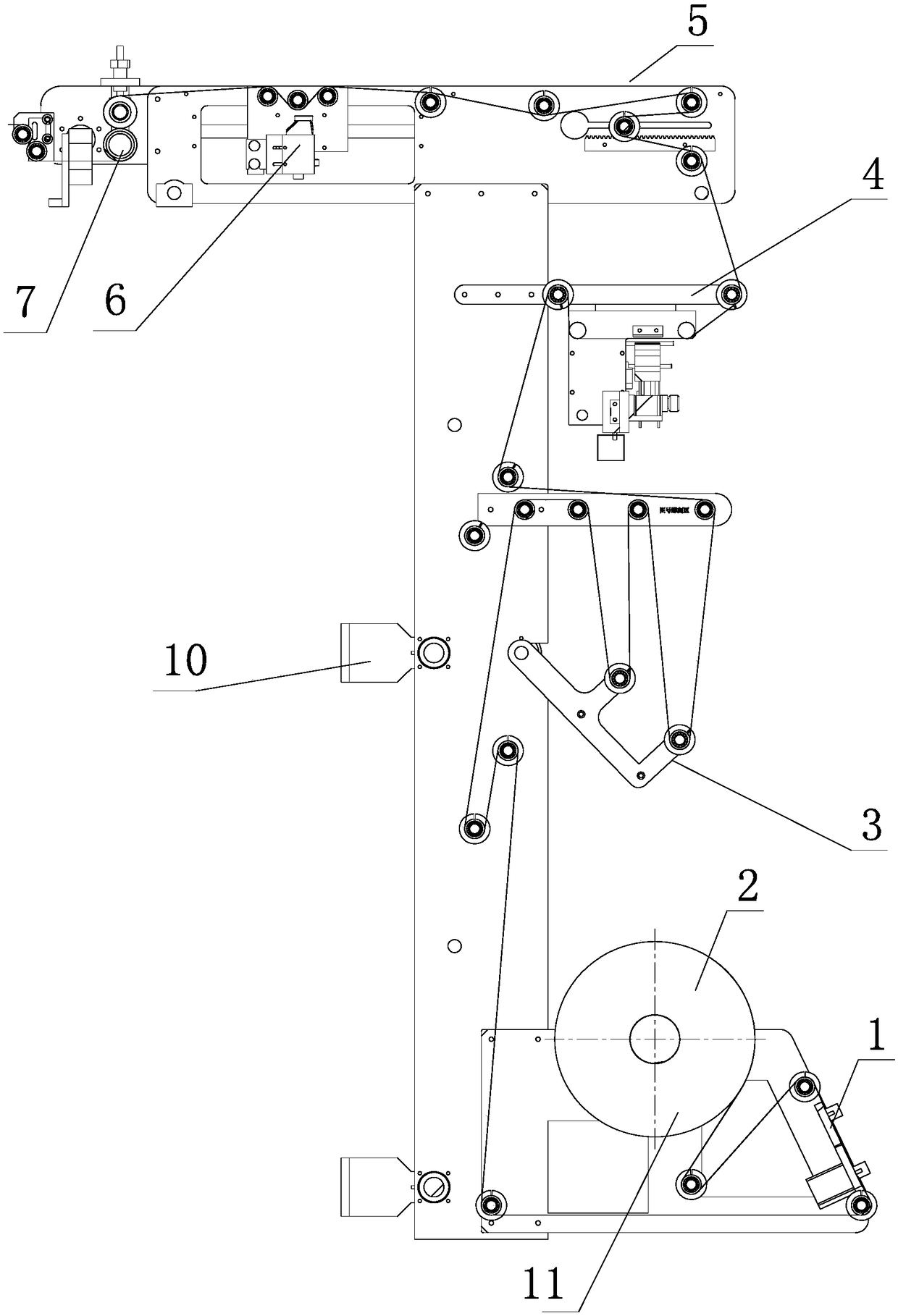

Efficient paper conveying device used for bag package mechanical production equipment

PendingCN109292509ARealize the automatic correction function of deviationWith automatic deviation correction functionWebs handlingRolling paperControl system

The invention discloses an efficient paper conveying device used for bag package mechanical production equipment. The efficient paper conveying device comprises a paper film changing mechanism and a swing shaft roller tensioning and alarming mechanism, wherein the paper film changing mechanism is arranged at the bottom of a paper supporting frame, and the swing shaft roller tensioning and alarmingmechanism is arranged in the middle of the paper supporting frame. Two horizontal plates are fixed to the top of the paper supporting frame. A coding position adjustment mechanism is arranged betweenthe two horizontal plates. Tracking optoelectronic switch position adjustment mechanisms are arranged on the two horizontal plates. A film damping mechanism is arranged at the rear end of the top ofthe paper supporting frame. A paper film deviation rectifying mechanism is also arranged on the paper supporting frame. In the paper conveying process, a roll paper film driving motor continuously operates in small-fluctuation and speed-variation modes, so that a swing arm of a swing shaft roller of the paper conveying device is kept swinging by a small angle within a small range, and the rotatingspeed of the roll paper film driving motor is automatically matched with the paper consuming speed of a packaging machine in the continuous operating process; and when the movement range is too largeand exceeds a set value, an encoder feeds a signal back to a control system to achieve automatic halts, an alarm is given when no film is available or when film supply is abnormal, and thus, continuous and stable tension is provided for a paper supply system.

Owner:天津瑞泰包装机械股份有限公司

Cabinet air conditioner with exhaust port sliding door

ActiveCN101344284BRealize automatic shutdownGuaranteed aestheticsLighting and heating apparatusPower-operated mechanismHydraulic cylinderEngineering

The invention provides a cabinet air conditioner which is provided with an automatic door at an exhaust port, has simple structure, low cost, smooth slide and can be conductive to the market competition and ensure long-term effective use, and the cabinet air conditioner can optimize the problems of noise and stability of the sliding door of the cabinet air conditioner during sliding. The cabinet air conditioner comprises: a cabinet body of the air conditioner, an upper panel body, a lower panel body, a sliding door part, a door drive device and an air outlet frame, wherein, the door drive device comprises a hydraulic transmission device and a connecting plate device; the hydraulic transmission device and the connecting plate device are positioned at the bottom part of the sliding door; the hydraulic transmission device comprises a hydraulic cylinder and a piston which is positioned at the position of an opening at the top surface of the hydraulic cylinder and can move up and down; thetop part of the connecting plate device is connected with the bottom part of the sliding door in a fastening way, and the bottom part of the connecting plate device is connected with the piston by a fastening device.

Owner:GREE ELECTRICHEFEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com