Full automatic tooling clamp for semi-crankshaft finish machining

A jig, fully automatic technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of difficult to guarantee processing accuracy, low production efficiency, inaccurate positioning, etc., to reduce product rejection rate, improve Production efficiency, the effect of eliminating workpiece errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is attached Figure 1-Figure 9 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

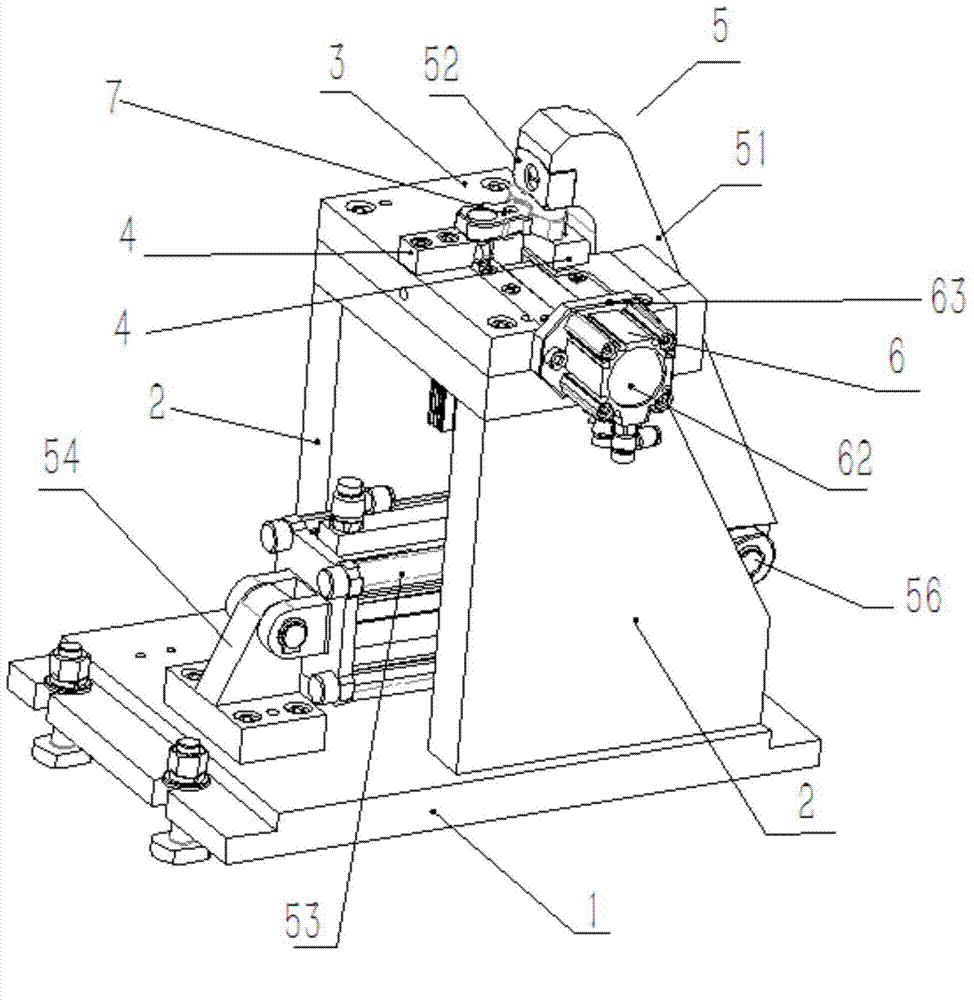

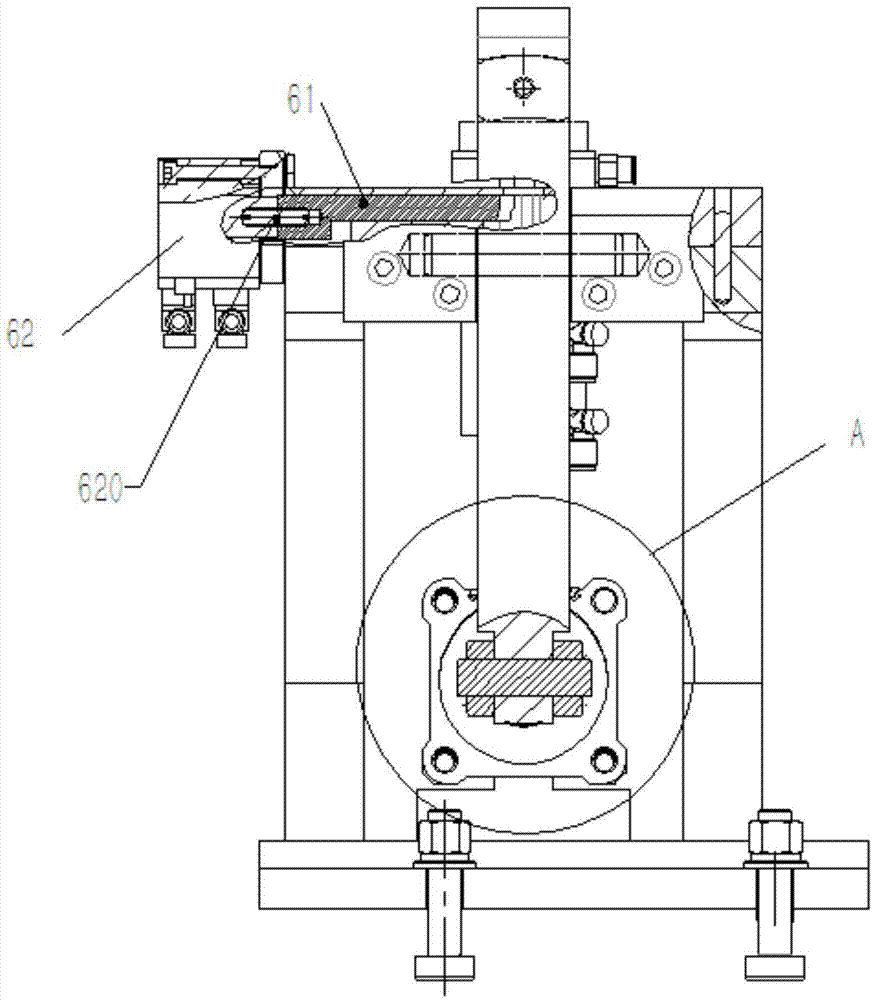

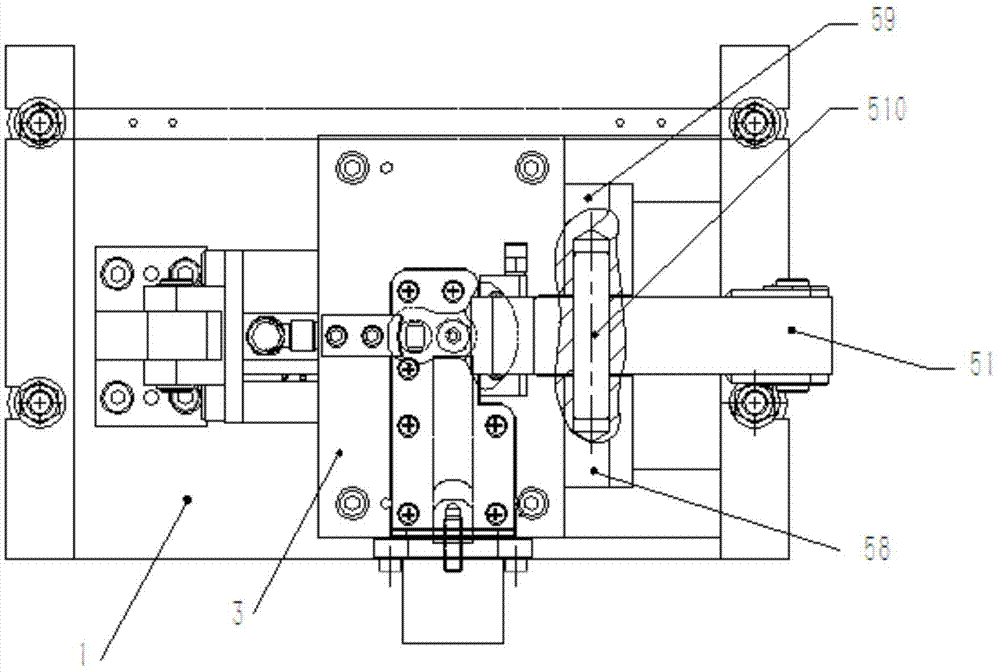

[0027] like figure 1 As shown, the invention includes a base 1, two side plates 2, a cover plate 3, two positioning blocks 4, a floating pressing mechanism 5, a positioning pin 8 and a radial pressing mechanism 6. The bottoms of the two side plates 2 are fixedly welded on the base 1; the cover plate 1 is fixedly connected to the top of the two side plates 2 by screws, and the two side plates and the cover plate form a "door" shape. A floating compression cylinder 53 is installed in the "gate" structure, which makes full use of the space of the structure and has a compact structure. Moreover, the cover plate 1 and the side plate 2 also play a protective role, preventing the iron filings and other sundries generated du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com