Full magnet-pasting machine

A magnetic machine, fully automatic technology, applied in the direction of labeling machine, labeling, labeling, etc., can solve the problems of affecting the quality of lamination, low feeding accuracy, low production efficiency, etc., to achieve high lamination firmness, automatic feeding and The effect of receiving materials and structure is simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

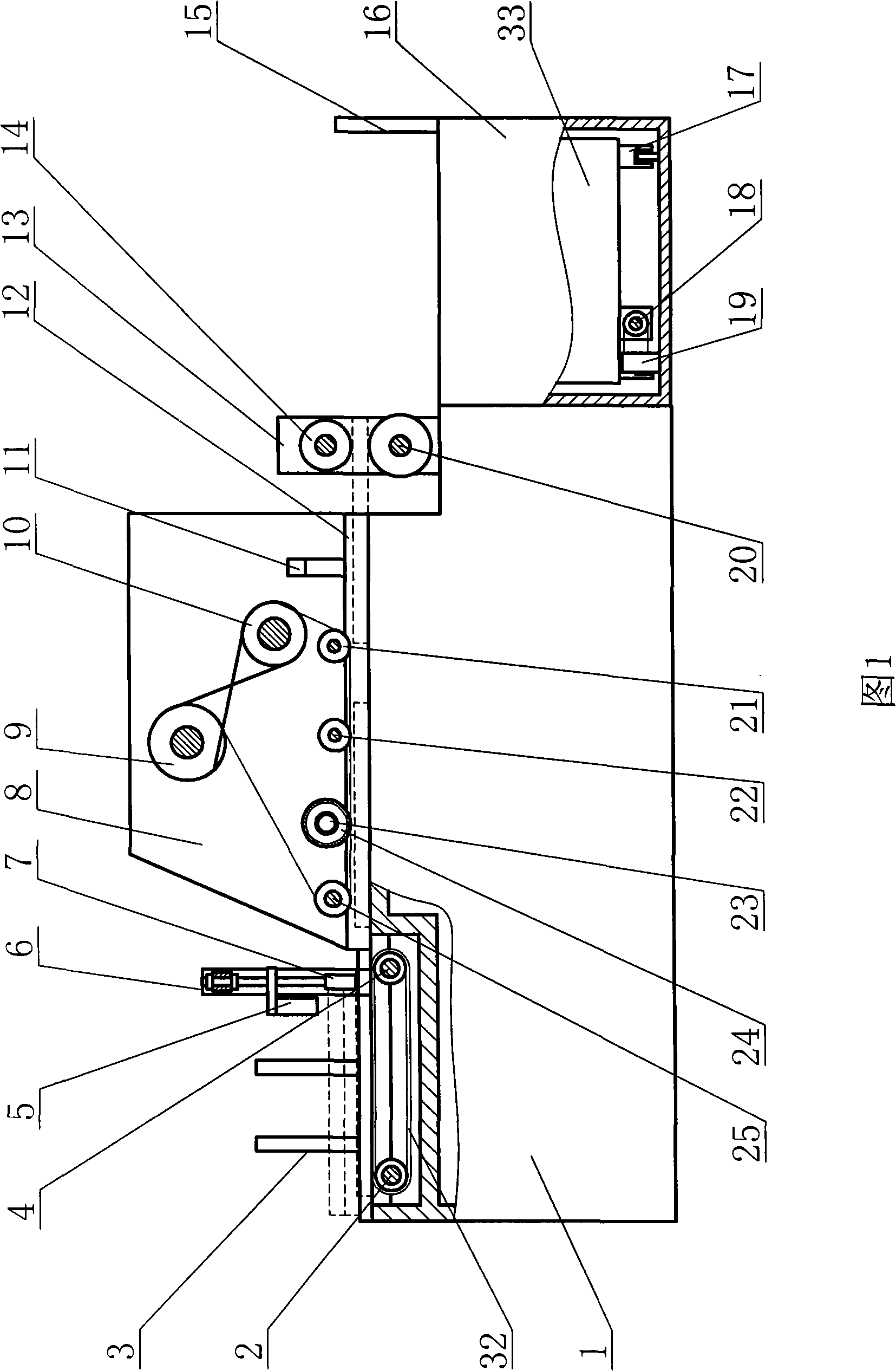

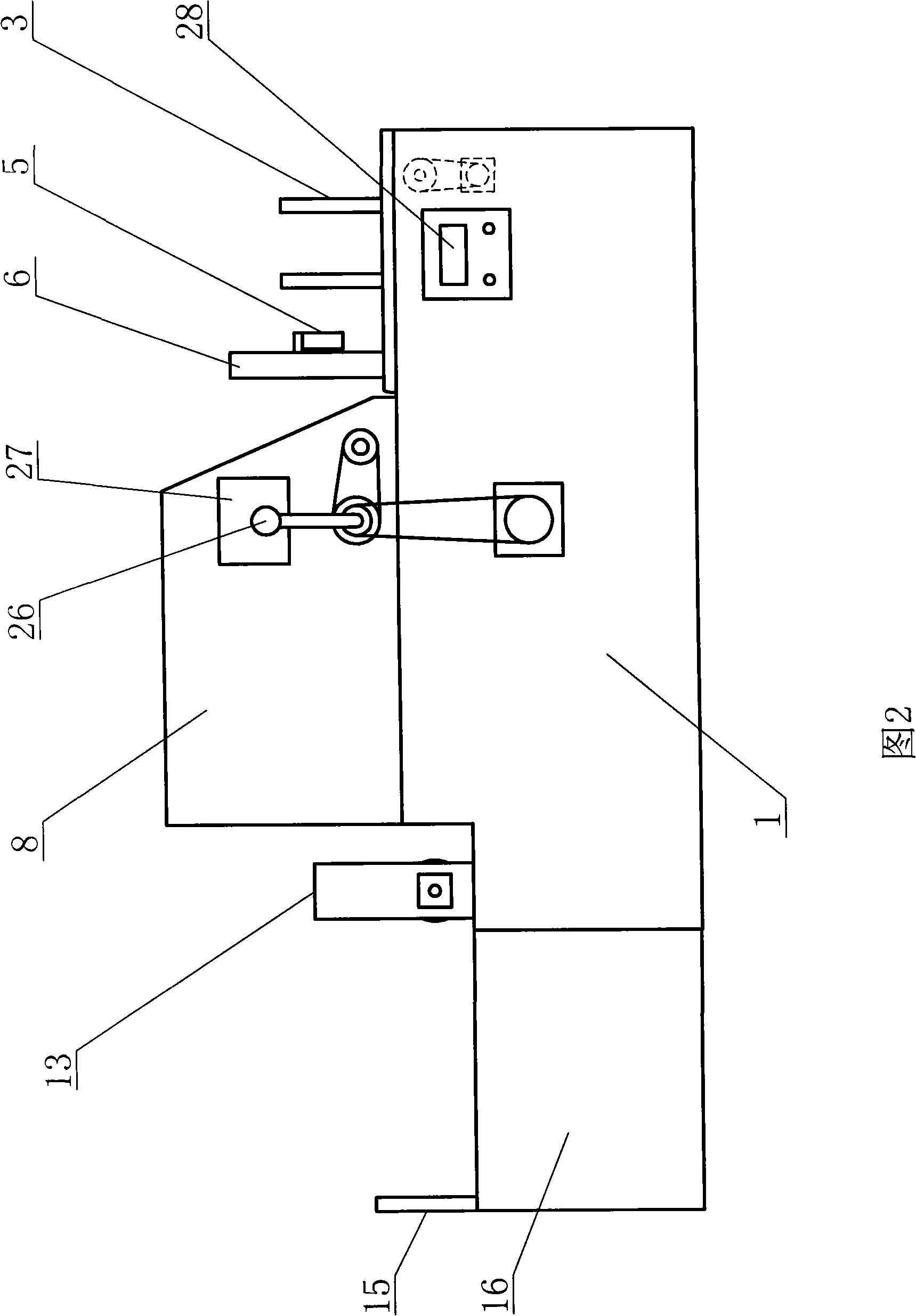

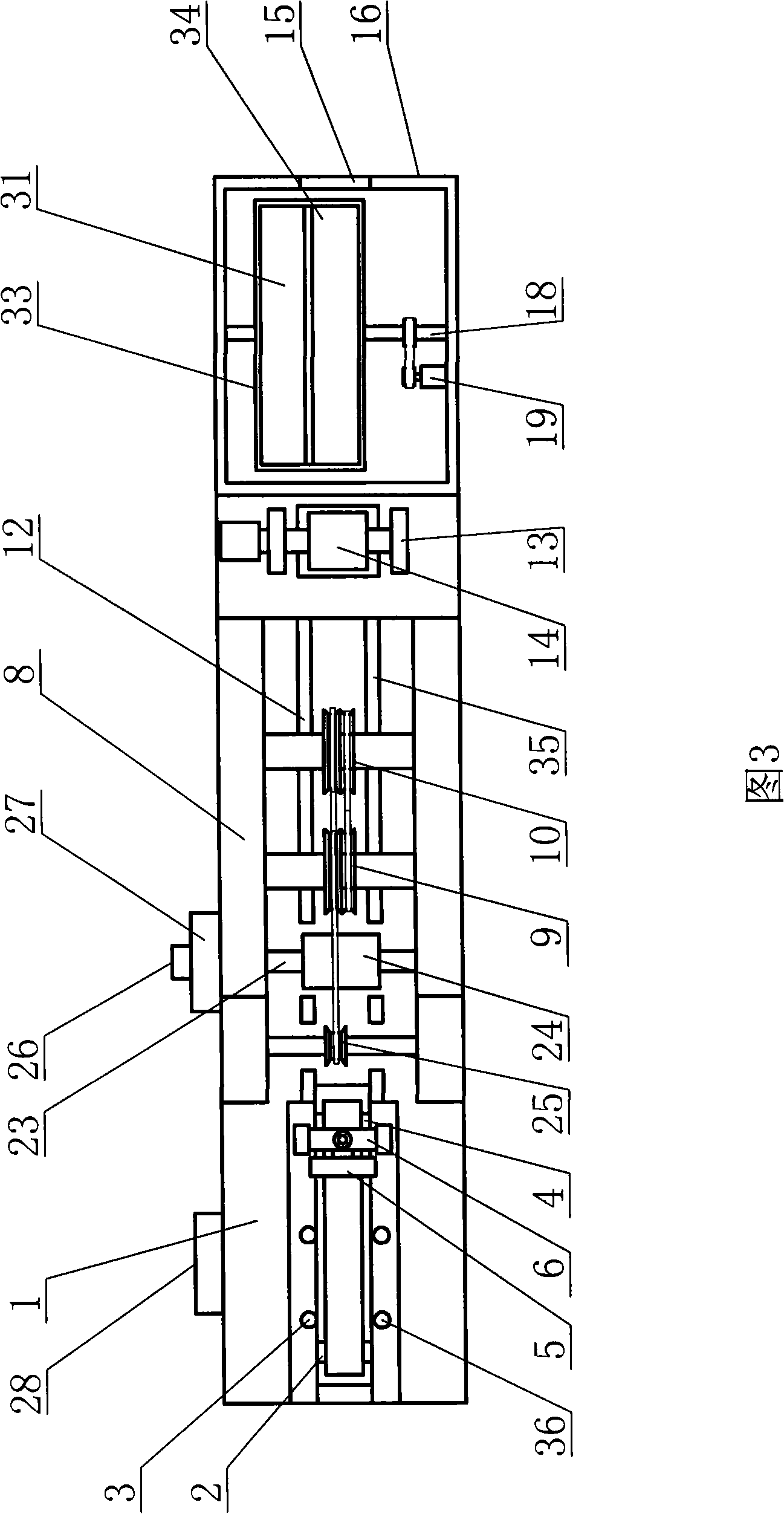

[0007] The main structure of the present invention is workbench 1, and front support 6, main support 8, rear support 13, console 28 and power unit are set on workbench 1, and front support 6, main support 8 and rear support 13 all can directly and work Station 1 is made as a whole. Magnetic stripe wheel 9 and receipt wheel 10 are installed on main support 8 tops, and belt is installed between magnetic stripe wheel 9 and receipt wheel 10, keeps synchronous rotation, and magnetic stripe wheel 9 is provided with the magnetic strip to be pressed, and receipt wheel 10 and The magnetic stripe on the magnetic stripe wheel 9 is connected, and the magnetic stripe wheel 9 rotates to convey the magnetic stripe, while the receipt wheel 10 rotates and takes back the used magnetic stripe after laminating. The main support 8 bottom installs guide wheel 25, rotating shaft 23, pressure roller 22 and guide wheel 21 successively from front to back, and power unit is connected with guide wheel 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com