An auxiliary device for tiling tiles on an indoor wall and a tiling process

An auxiliary device, a technology for tiling tiles, which is applied in the directions of covering/lining, architecture, building structure, etc., can solve the problems of uneven tile bonding, uniform tile plastering, and hollow tiles, etc., to increase the bonding firmness. degree, increase the coverage area, and the effect of high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-5 The application is described in further detail.

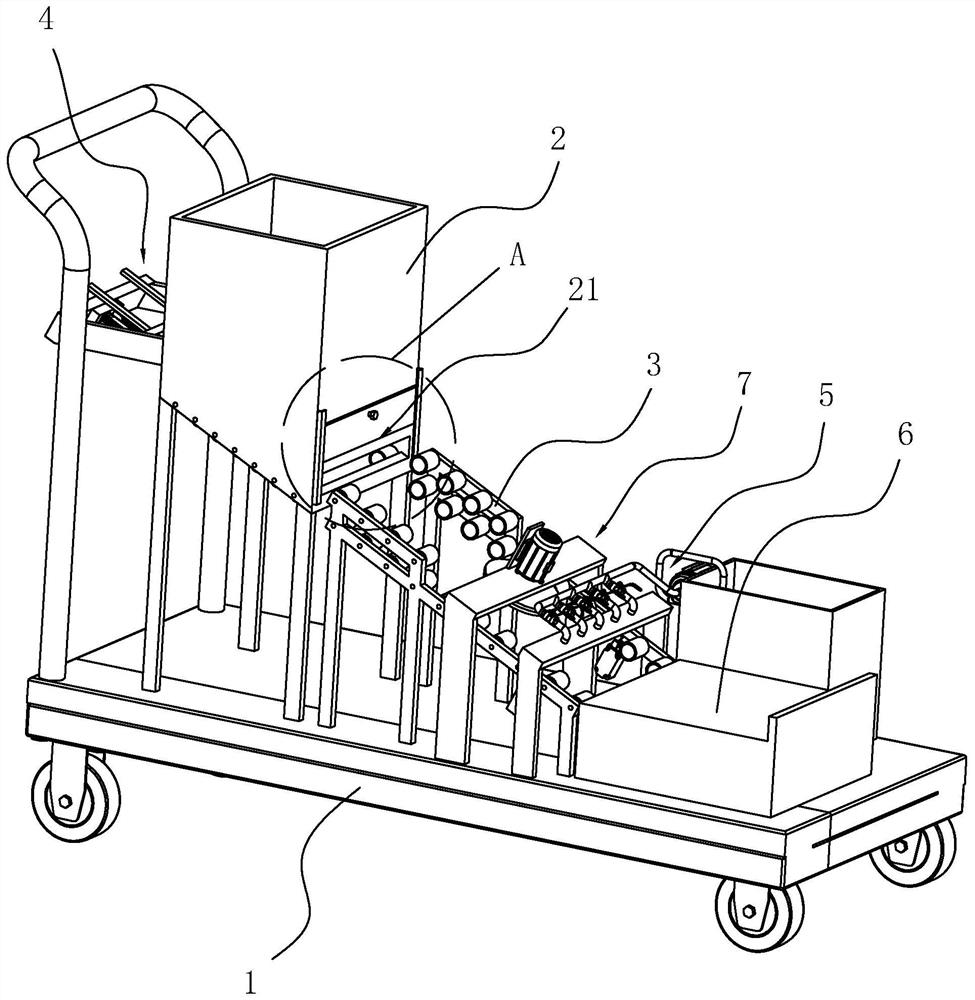

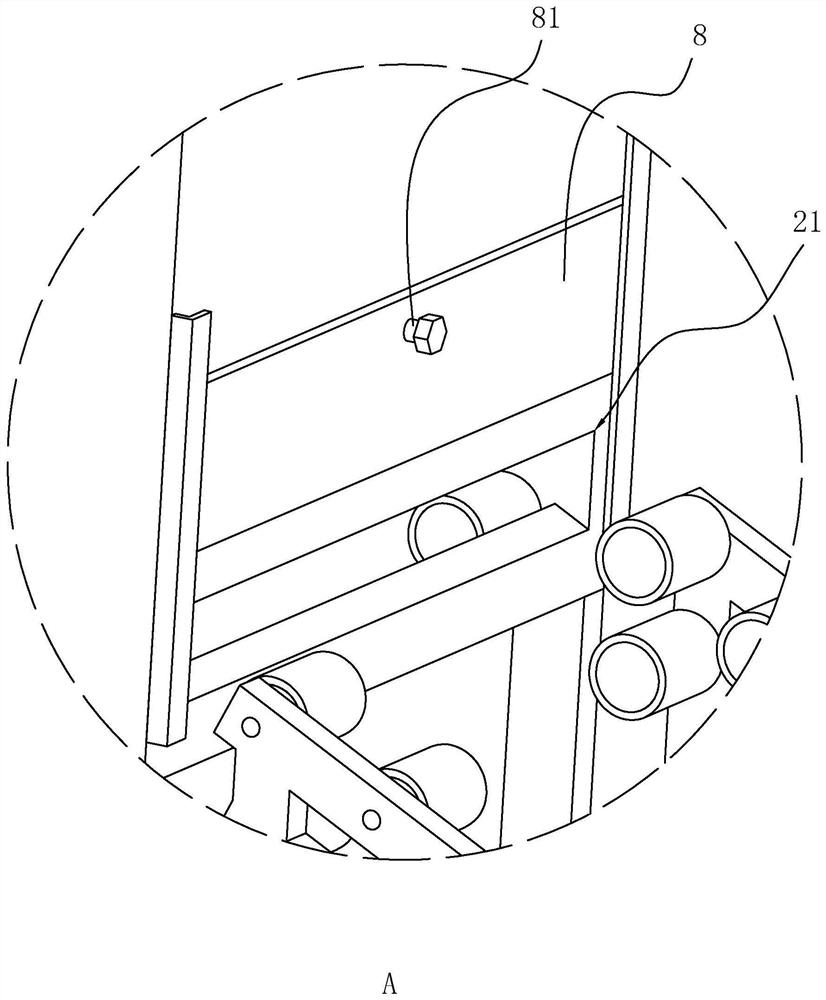

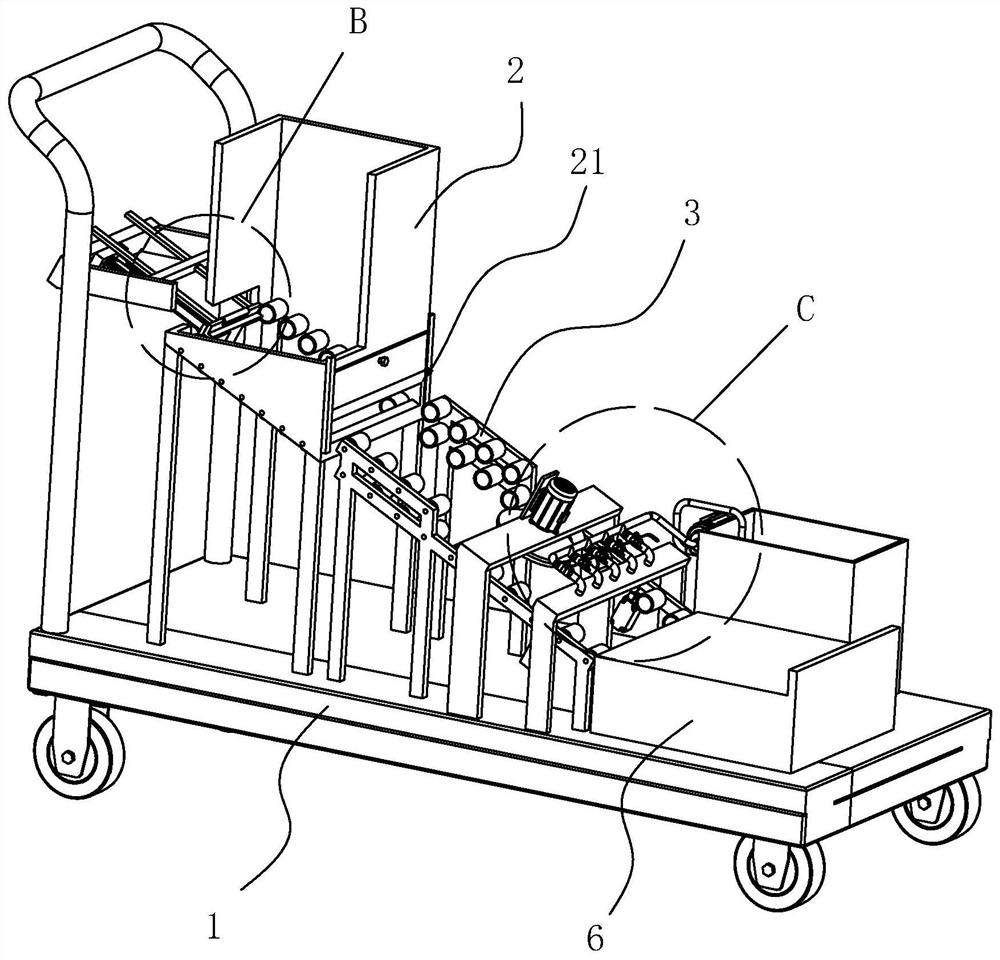

[0044] The embodiment of the present application discloses an auxiliary device for tiling tiles on indoor walls. refer to figure 1 , 2 , the auxiliary device includes a vehicle frame 1, the vehicle frame 1 includes a base, universal wheels are installed on the bottom of the base, and can be moved on the ground by the staff as the brick laying work progresses. A mounting frame is installed on the frame 1, and the top of the mounting frame is a storage box 2, which is used to store tile stacks in advance. The middle part of the mounting frame is a conveyor rail 3 installed at an angle. Platform 6, the supply staff takes materials from here. A baffle is raised up on the edge of the retrieving platform 6 away from the conveying rail 3 to prevent the tiles from sliding out of the retrieving platform 6 . The higher end of the conveying rail 3 is docked on the bottom edge of one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com