Casting pouring metal-stream inoculation automatic monitoring system

An automatic monitoring system and inoculation technology with flow, which is applied to casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problem that the outflow of inoculant with flow cannot be measured and monitored continuously in real time, abnormal inoculant outflow, etc. problems, to achieve superior performance, reduce defective products, and add timely effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to solve the above-mentioned defects, the inventors of the present application invented and created an automatic inoculant monitoring device.

[0018] The following structural drawings describe the application in detail,

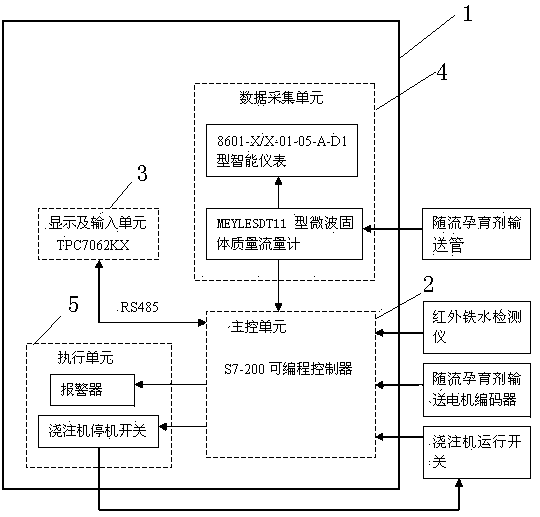

[0019] The automatic monitoring system for casting pouring and inoculation with flow includes a system control cabinet 1, a main control unit 2, a display and input unit 3, a data acquisition unit 4, and an execution unit 5. The main control unit can adopt various programming controllers of companies such as Siemens in the prior art, and the S7-200 programmable logic controller (PLC) used in this application, and the display and input unit adopts a TPC7062KX touch screen, which can input parameters And display data, draw flow curve. The main control unit is installed inside the system control cabinet, the display and input unit is installed on the front panel of the system control cabinet, and the display and input unit is connected to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com