Adjustable plug-in type flexible grouting device

A plug-in, grouting technology, applied in the field of adjustable plug-in flexible grouting, can solve problems such as affecting grouting efficiency and slowing down the progress of work, and achieve the effect of improving work efficiency and speeding up the progress of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

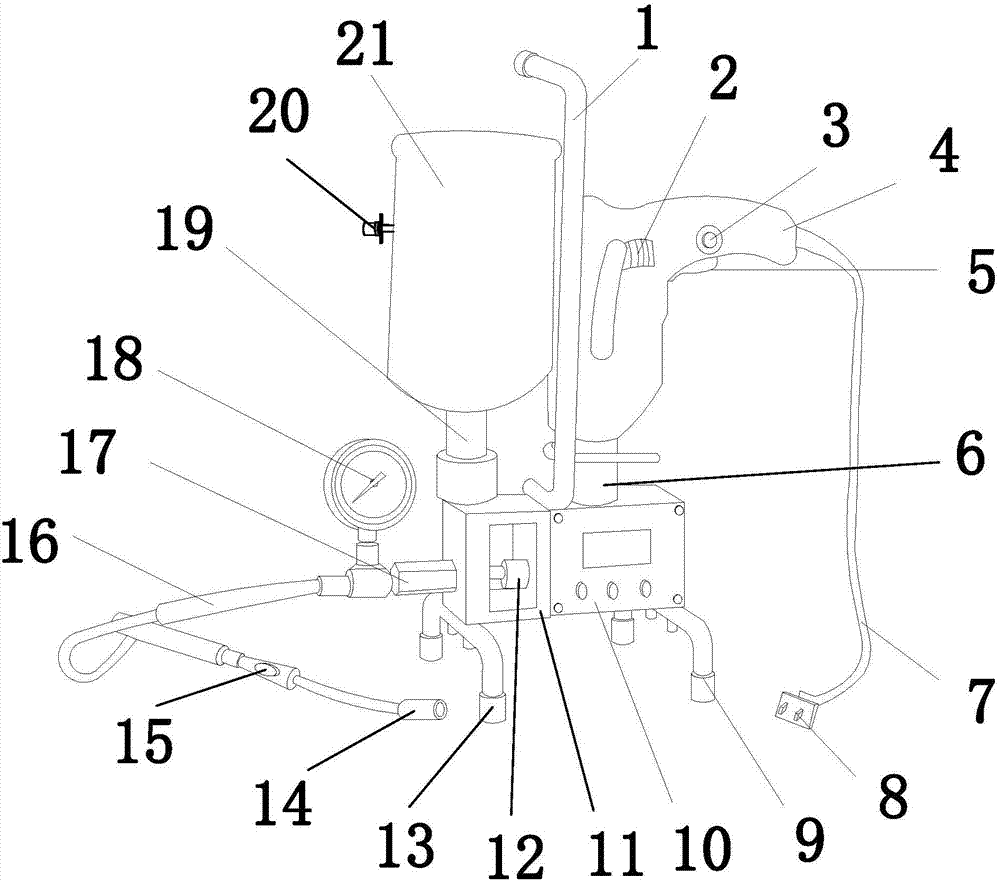

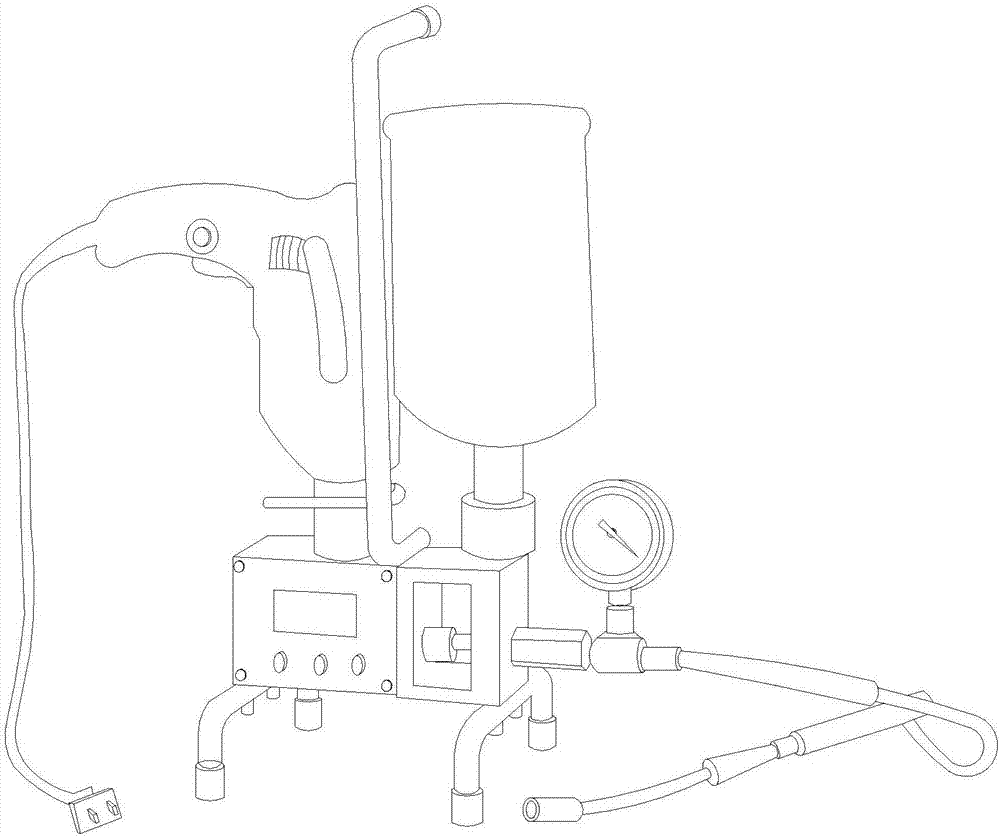

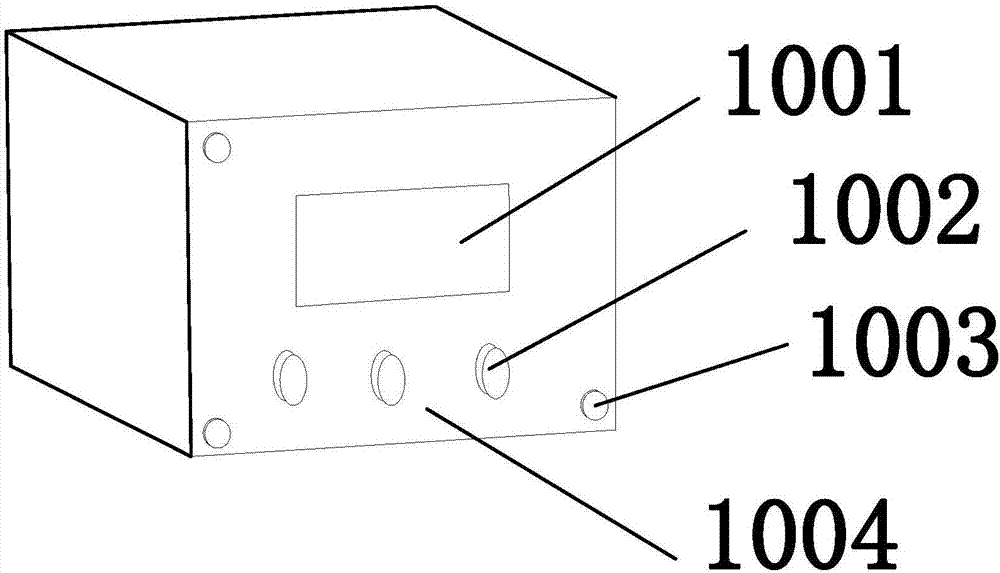

[0031] see Figure 1-Figure 8 , the present invention provides a technical solution of an adjustable plug-in flexible grouter: an adjustable plug-in flexible grouter, the structure of which includes a handle 1, an electric drill cooling hole 2, a fixed lock button 3, and a driving electric drill 4 , trigger 5, fixed column 6, connecting wire 7, power plug 8, right support foot 9, gearbox 10, stainless steel outer protective frame 11, piston 12, left support foot 13, grouting head 14, tank filling switch button 15. High pressure pipe 16, booster cylinder 17, pressure gauge 18, transmission pipe 19, liquid level sensor 20, material cup 21:

[0032] The handle 1 is a U-shaped structure, the lower end of the handle 1 is welded between the gearbox 10 and the upper surface of the stainless steel outer protective frame 11, and the fixing column 6 is installed on the right side of the handle 1 and welded vertically Above the gearbox 10, the driving electric drill 4 is vertically fixe...

Embodiment 2

[0039] see Figure 1-Figure 8 , the booster barrel 17 is provided with an oil cylinder 1701, a booster copper guide sleeve 1702, a flange steel plate 1703, a front rod 1704, and a double-layer sealing head 1705, and the booster barrel 17 is an improved design combining the advantages of the cylinder and the oil cylinder , the hydraulic oil is strictly isolated from the compressed air, the piston rod in the cylinder starts automatically after touching the work piece, the action speed is fast, and it is more stable than the pneumatic transmission, the cylinder body device is simple, and the output is easy to adjust. The flange steel plate 1703 is equipped with two , the oil cylinder 1701 is horizontally fixed on the left side of the flange steel plate 1703 on the right side, the pressurized copper guide sleeve 1702 is embedded in the flange steel plate 1703, the front rod 1704 vertically penetrates the flange steel plate 1703 and is connected with the increased The copper pressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com