Ironing machine for ties

A tie ironing machine and ironing machine technology, which is applied in ironing machines, washing devices, textiles and papermaking, etc. It can solve the problems of large influence of human factors, accidental scalding of hands, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

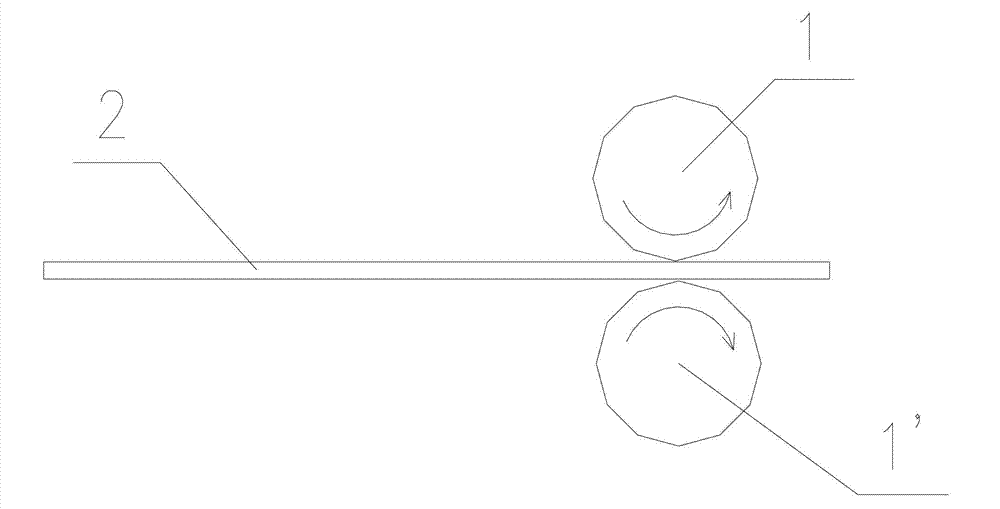

[0020] A tie ironing machine, comprising at least two elastically compressed rollers (1,1'), the surfaces of the rollers (1,1') are provided with a heating layer, and the heating layer includes A thick film circuit layer and an insulating layer overlying the thick film circuit layer. Thanks to the thick film circuit layer heating, rolling and ironing can be combined in one, saving space.

[0021] A driving motor is installed, and the driving motor drives the two rollers (1, 1') to rotate inwardly through gears, belts or chains, and drives the tie to pass between the rollers. A power module is installed, and the power module provides power for the driving motor and the thick film circuit layer. The power module is a dry cell or a storage battery. Since the tie ironing machine provides a removable power source, it can be used anytime and anywhere, which is very convenient for business trips and travels.

[0022] The two rollers are elastically compressed by springs. To ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com