Sewing machine and stitch-length adjusting and backstitch control method for sewing machine

A needle pitch adjustment and sewing machine technology, which is applied to the sewing machine control device, the mechanism for cutting the thread in the sewing machine, and the sewing machine components, etc., to achieve the effect of beautiful stitches, precise stitch size, and small interaction between dimensional tolerances and fit tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

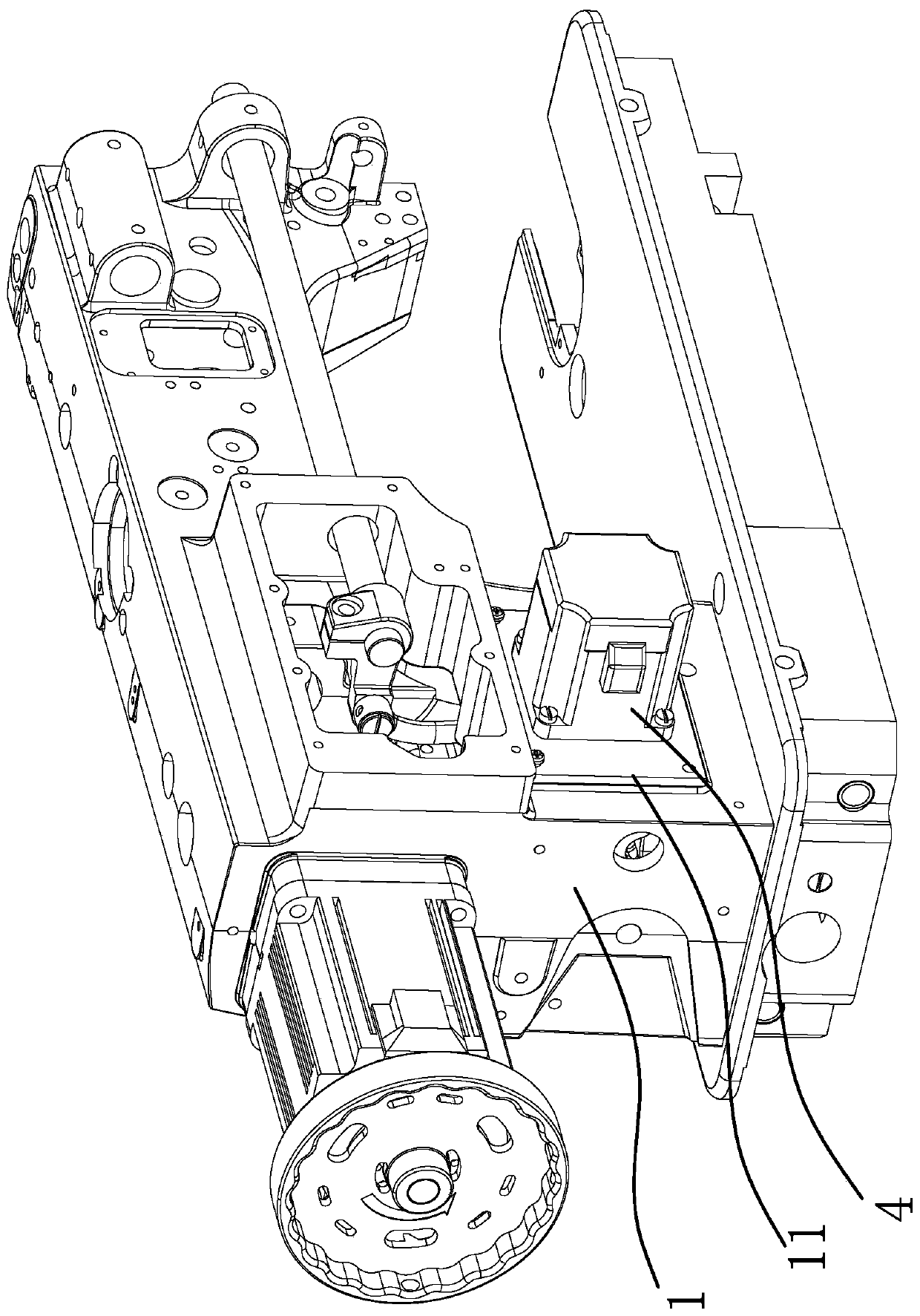

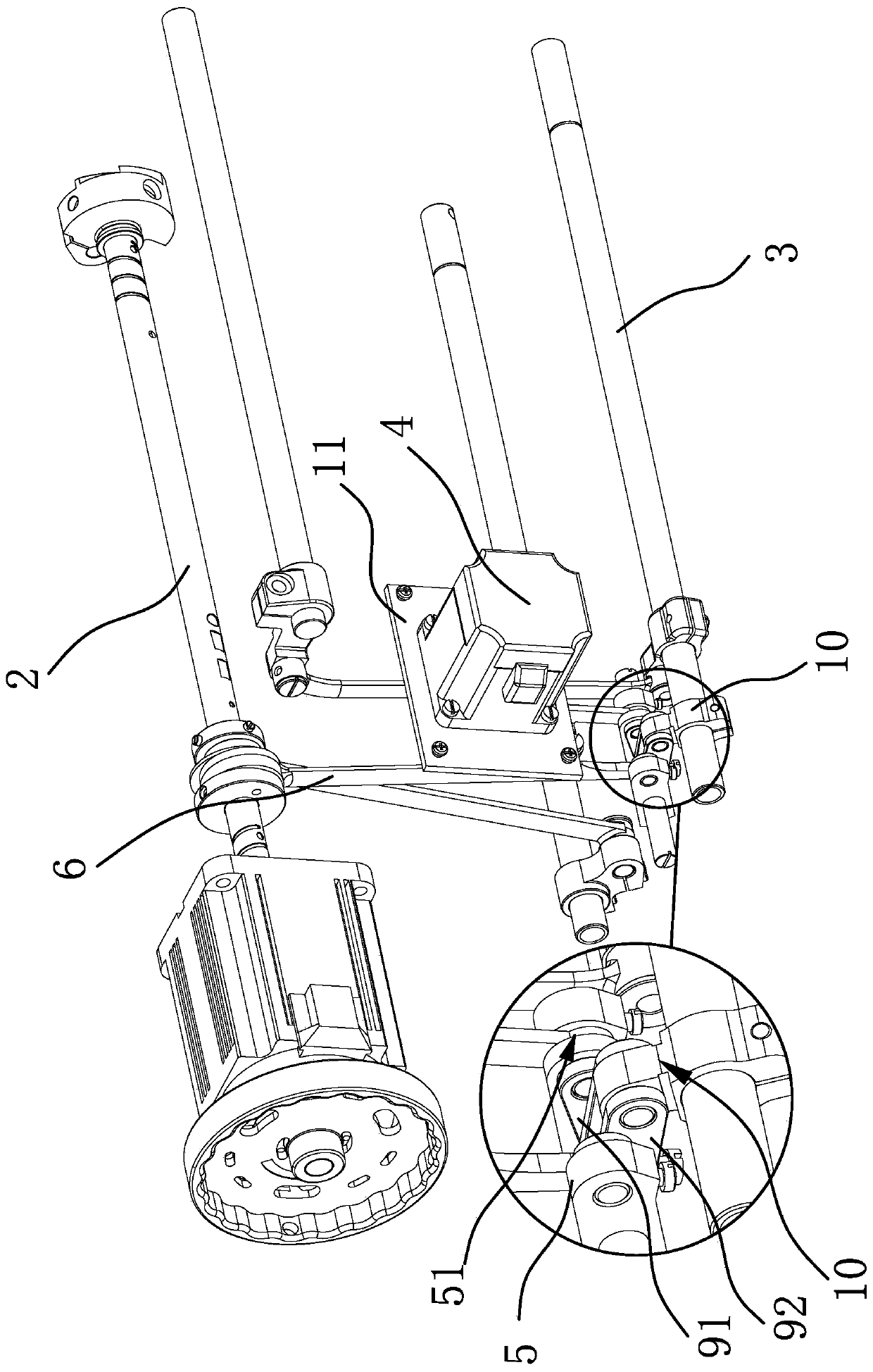

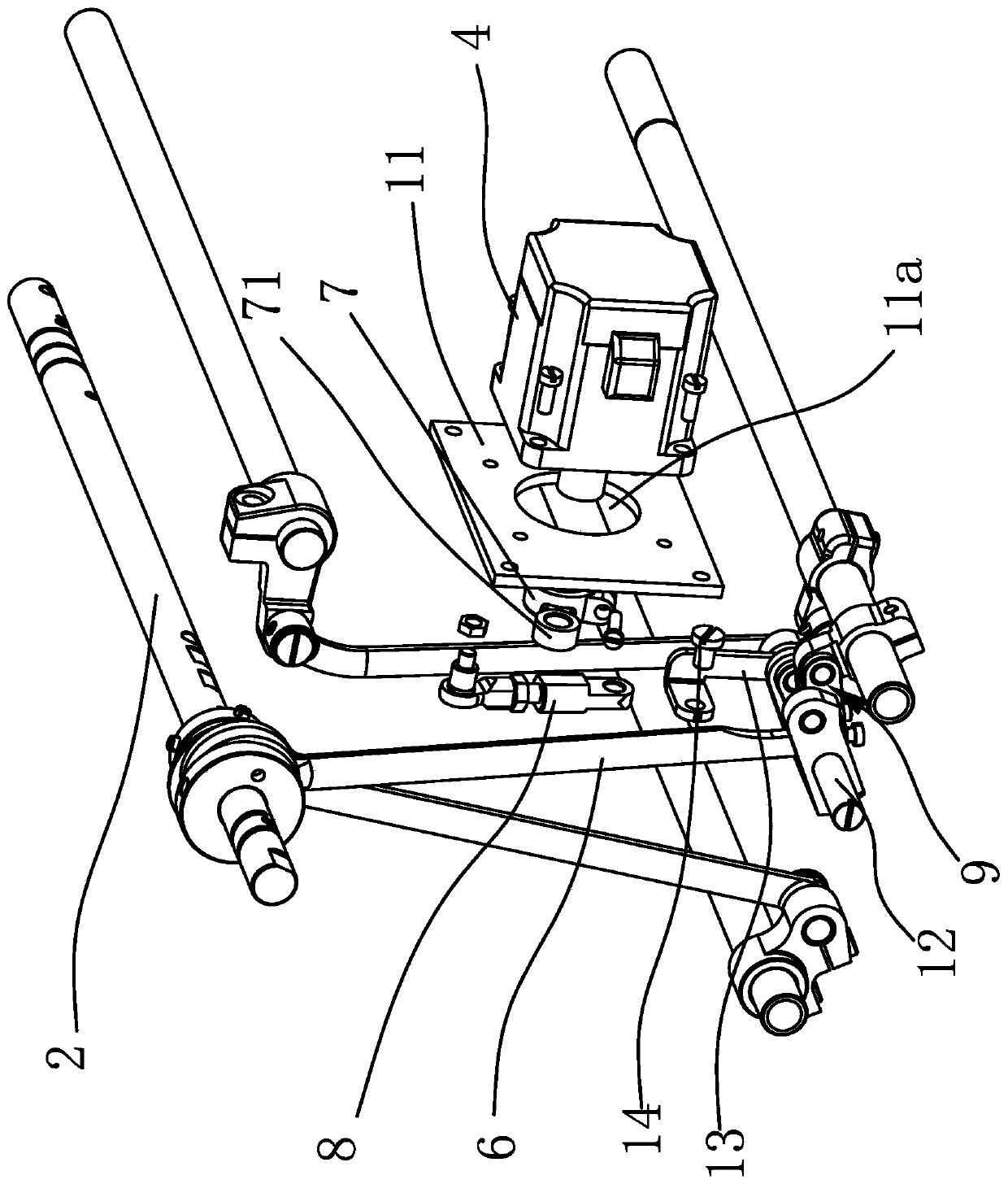

[0044] like figure 1 , figure 2 and image 3 As shown, the sewing machine includes a casing 1, an upper shaft 2, a feed shaft 3, a drive motor 4, and a needle pitch adjustment crank 5 arranged between the upper shaft 2 and the feed shaft 3. The stitch length adjustment crank 5 can swing and the upper shaft 2 is connected with the needle distance adjustment crank 5 through the feeding connecting rod 6; the output shaft of the drive motor 4 is fixed with a motor crank 7, and the output shaft of the drive motor 4 has a reference groove 41; the motor crank 7 and the needle distance adjustment crank 5 They are connected by an adjusting link assembly 8; the feed shaft 3 is fixed with an axel 10, and the axel 10 is connected with the pitch adjusting crank 5 by a crank link assembly 9.

[0045] Further, such as figure 1 and figure 2 As shown, the driving motor 4 in this embodiment is a stepping motor; the casing 1 is fixedly provided with a mounting plate 11, the driving motor 4...

Embodiment 2

[0051] This embodiment discloses a stitch length adjustment and backstitch control method of a sewing machine, which is characterized in that the control method includes the following steps:

[0052] a. Turn on the power, and before sewing the sewing machine, judge whether it is necessary to adjust the stitch length according to the sewing material and sewing process requirements;

[0053] b. If it is necessary to adjust the stitch length, adjust the required stitch length through the electric control parameters, and then set the number of stitches required for backtacking; if it is not necessary to adjust the stitch length, directly set the number of stitches for the required backtacking;

[0054] c. Depress the pedal to start sewing, and the front reinforcement seam will be automatically performed at the beginning of sewing;

[0055] d. After sewing, depress the pedal to give the thread trimming signal;

[0056] e. Electronic control automatically completes the rear reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com