Novel intelligent template sewing machine and automatic induction sewing method

A lockstitch machine and template technology, applied in the field of lockstitch machines, can solve the problems of fabric tearing, safety hazards, motor heat being easily damaged, and blocking template movement, etc., so as to improve the sewing effect, prevent wrinkling, and improve sewing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

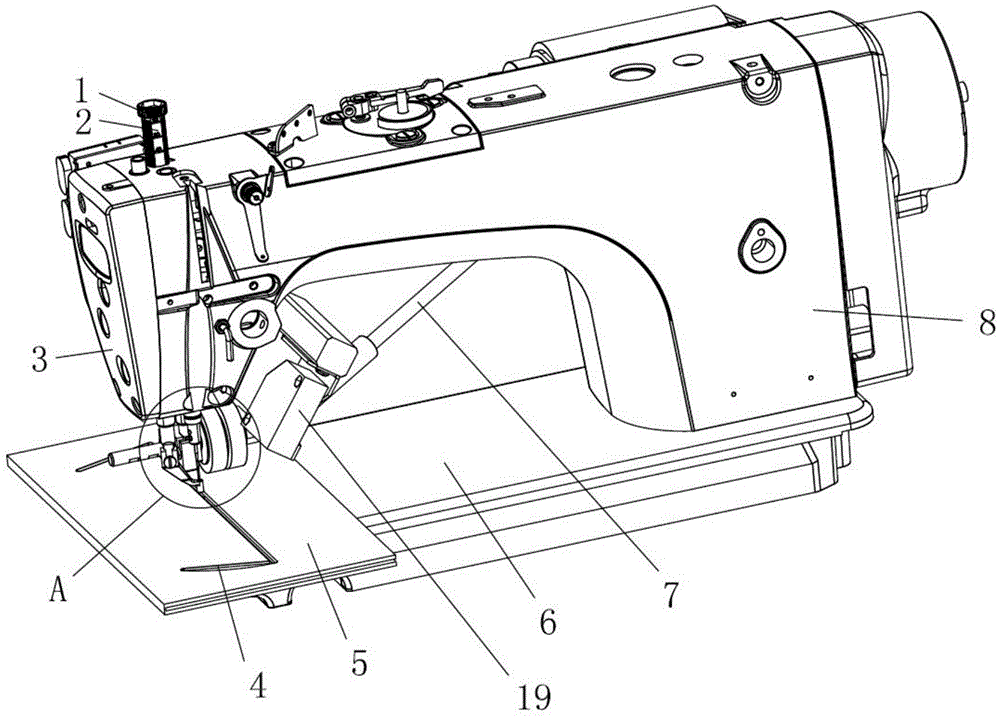

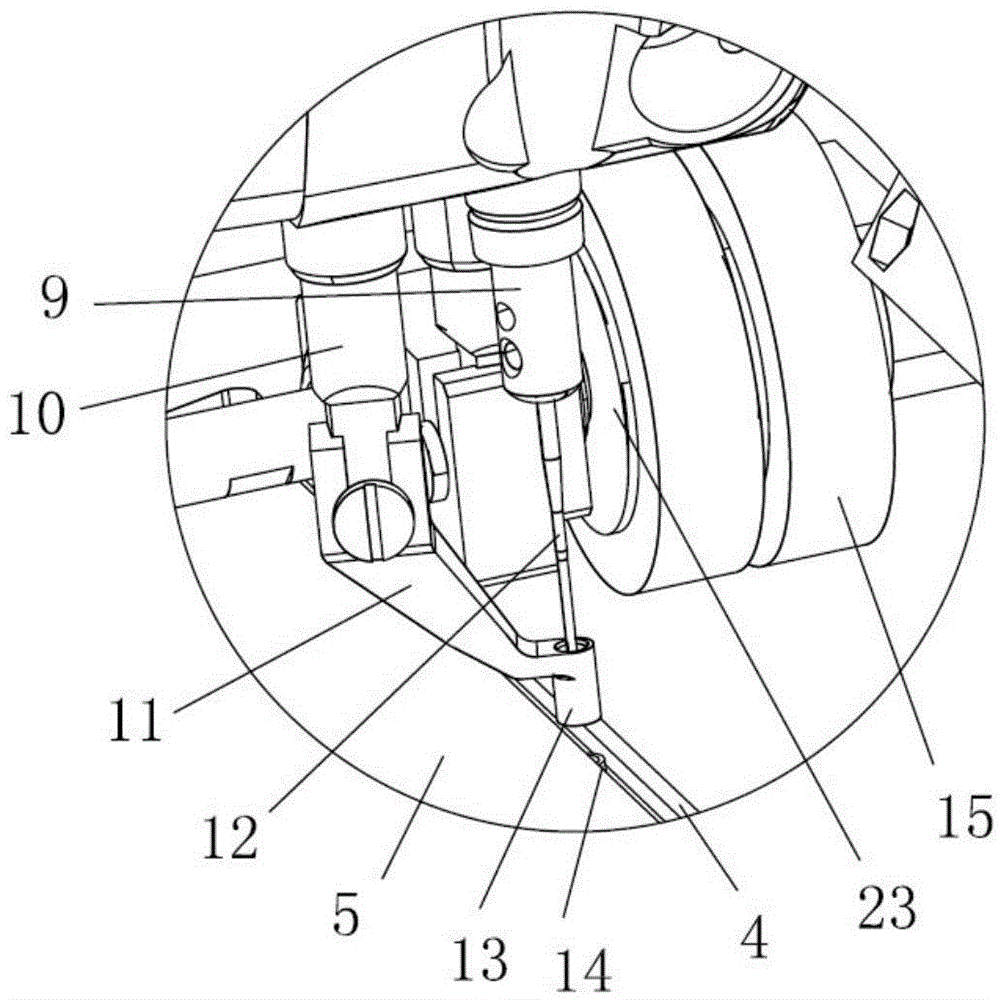

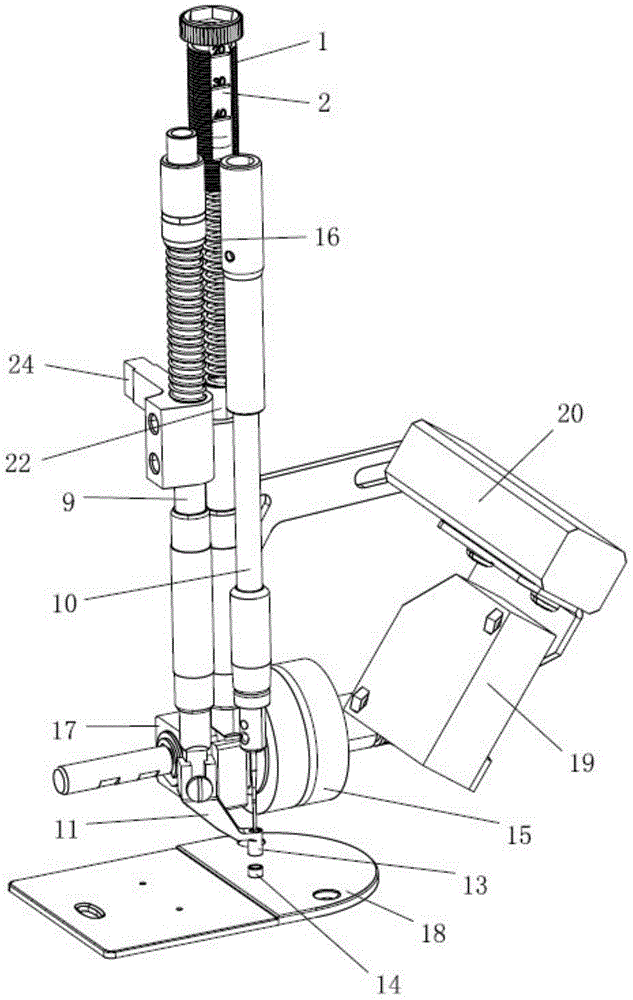

[0031] A novel intelligent template lockstitch sewing machine comprises a casing 8 on which a mop mechanism, a template photoelectric sensor 19 and a controller (the controller is used to control the orderly operation of each component of the template lockstitch sewing machine, which can Built in the casing or installed on the back of the casing); on the needle plate 18 of the template lockstitch sewing machine (in this application, there is no feed dog installation hole on the needle plate, and it can be reserved in the needle plate during actual assembly. The mounting hole of the feed dog, so that the lockstitch machine can be multi-purpose), is provided with the lower guide sleeve 14 for the machine needle 12 to pass and hook the thread (the lower guide sleeve can be set to be detachable, so that the lockstitch machine can be multi-purpose), the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com