Sewing machine dust collection device

A dust collection device, sewing machine technology, applied in the direction of sewing machine components, sewing equipment, textiles and papermaking, etc., to achieve the effect of making up for the lack of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

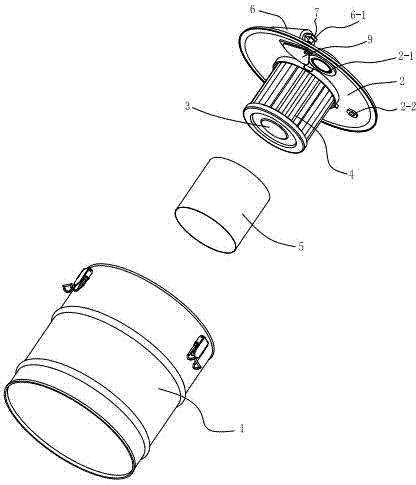

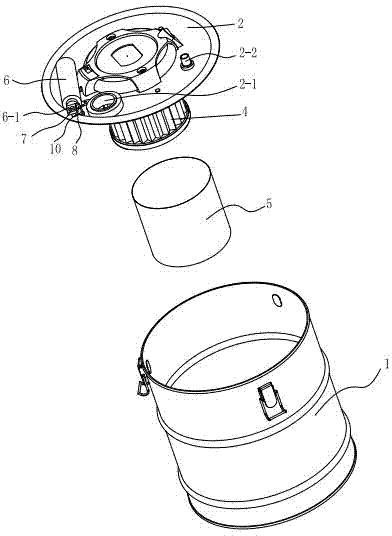

[0029] Such as figure 2 , image 3 As shown, the dust collection device of the sewing machine of the present invention includes a dust collection bucket 1, which is provided with an upper cover plate 2; the upper cover plate 2 is provided with a dust suction port 2-1 and a suction pipe connection port 2-2 , The diameter of the mouth 2-1 after vacuuming is larger than the diameter of the connecting mouth of the suction pipe 2-2;

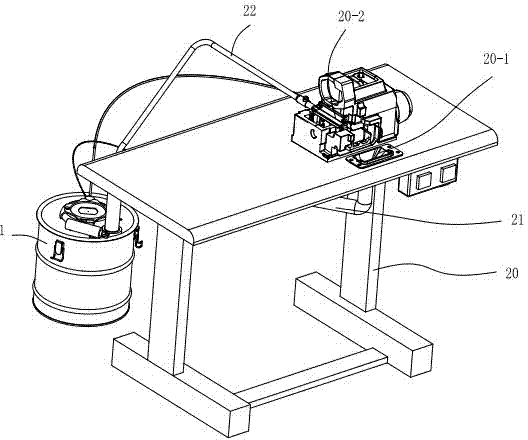

[0030] Such as figure 1 As shown, the upper cover 2 is connected to the end of the dust suction pipe 21 through the dust suction port 2-1, and the head of the dust suction pipe 21 is connected to the dust suction front mouth 20-1; the dust suction front mouth 20-1 is opened in the sewing machine 20 on the workbench;

[0031] The upper cover 2 is connected to the tail end of the thread suction tube 22 through the thread suction tube connection port 2-2. The head of the thread suction tube 22 is located on the side of the thread trimming mechanism 20-2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com