Cleaning structure for sewing machine

A sewing machine and chip cleaning technology, which is applied to sewing machine components, sewing equipment, textiles and papermaking, etc., can solve the problems of high cost, complicated device, inconvenient installation, etc., and achieve the effect of simple structure, strong versatility, and enhanced cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

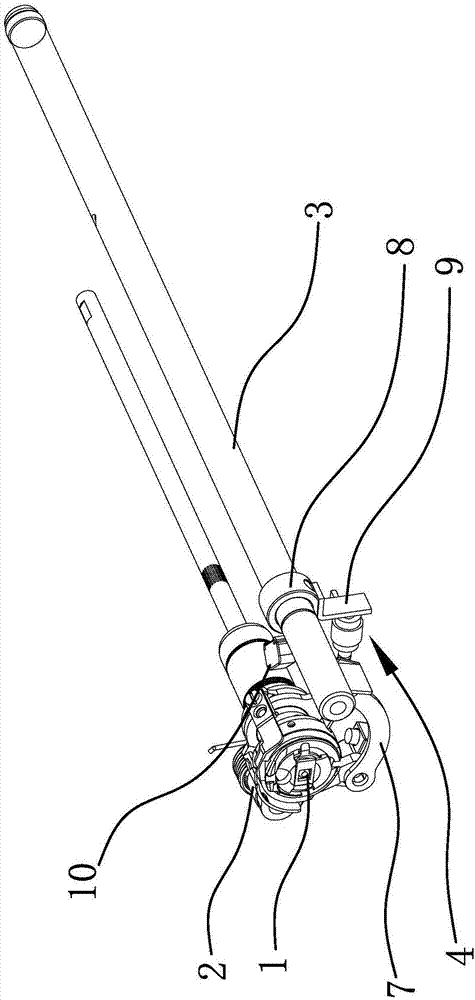

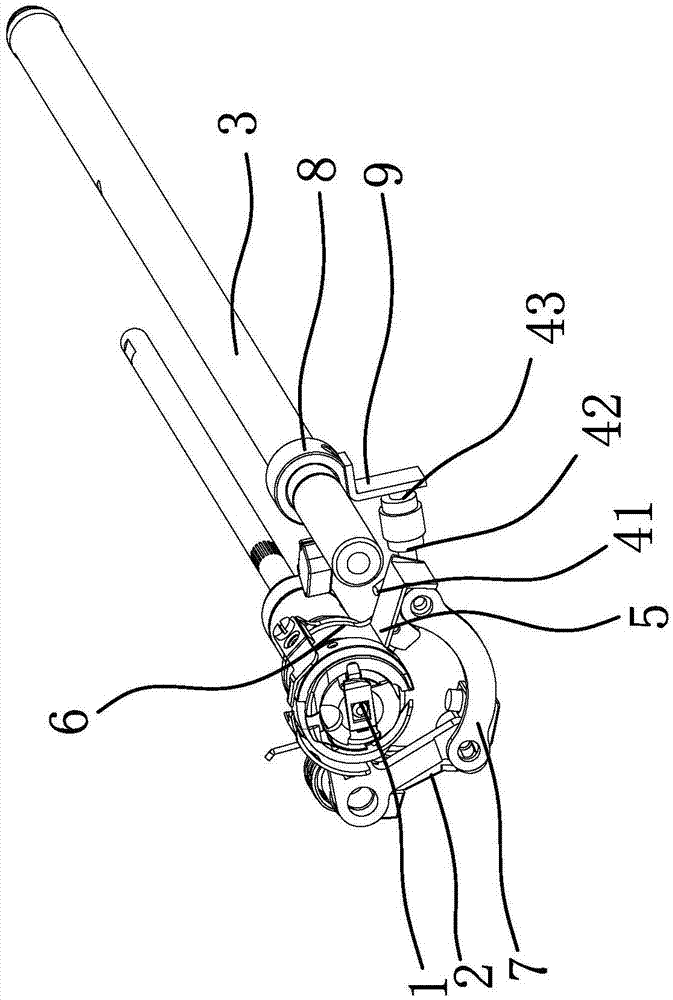

[0027] Such as Figure 1 to Figure 4 As shown, the sewing machine in this embodiment includes a rotary hook 1, a thread trimming crank 2 and a tooth lifting shaft 3, and the cleaning structure includes an air blowing assembly 4 and a chip cleaning board that can be driven by the thread trimming crank 2 or the tooth lifting shaft 3 to swing 5. The chip cleaning plate 5 is located outside the rotary hook 1; the blowing assembly 4 includes a blowing nozzle 41, a one-way valve 42 and a piston 43, the blowing nozzle 41 is located under the chip cleaning plate 5, the blowing nozzle 41 and the one-way valve 42 connected, the tooth lifting shaft 3 is connected with a drive plate 9 that can drive the piston 43 to reciprocate, and the movement of the piston 43 can supply air to the one-way valve 42; further, the sewing machine also includes a knife rest 6, and the chip cleaning plate 5 is fixed On the knife rest 6; the knife rest 6 is connected with the thread trimming crank 2 through t...

Embodiment 2

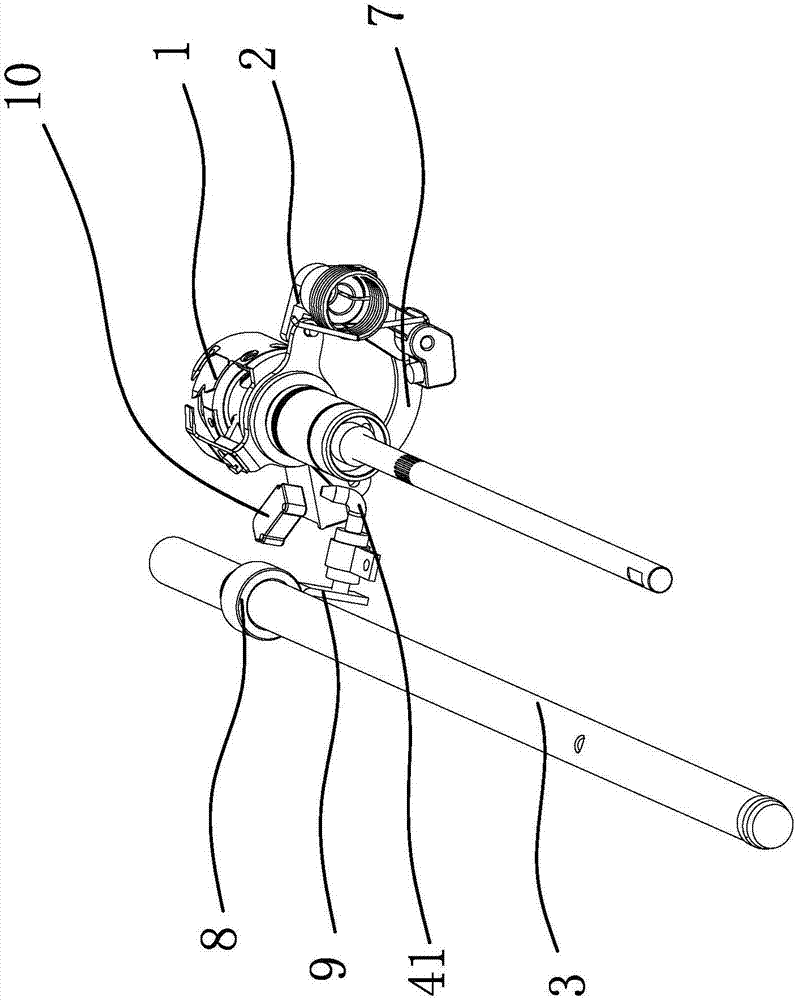

[0030]This embodiment is roughly the same as Embodiment 1, except that the sewing machine in this embodiment includes a thread-cutting cam crankshaft, a connecting rod 7 and a knife rest 6, and one end of the thread-cutting crank 2 is fixed on the thread-cutting cam crankshaft, and the other end The shaft screw is hinged with one end of the connecting rod 7, one end of the tool holder 6 is hinged at the head of the front bushing of the lower shaft, the other end of the tool holder 6 is hinged with the other end of the connecting rod 7 and the chip cleaning plate 5 is fixed on the connecting rod On this end of 7, when thread trimming is performed at the end of sewing, the crank shaft of the thread trimming cam rotates at a certain angle, driving the thread trimming crank 2 fixed on the crank shaft of the thread trimming cam, and the thread trimming crank 2 drives the connecting rod 7 to move, and the connecting rod 7 simultaneously It drives the shearing movement of the tool hol...

Embodiment 3

[0032] This embodiment is substantially the same as Embodiment 1 or Embodiment 2, the difference is that in this embodiment, a swing member is fixed on the tooth lifting shaft 3, and one side of the chip cleaning plate 5 is fixedly connected with the outer end of the swing member. When the sewing machine is working, the tooth lifting shaft 3 swings back and forth quickly at a certain angle, driving the swinging member to swing, so that the chip cleaning board 5 swings quickly, and the thread wool and oil mist adhering to the chip cleaning board 5 are thrown off under the action of inertia. To achieve the effect of cleaning waste, it also acts on the piston 43 of the air blowing assembly 4 through the drive plate 9, and combined with the check valve 42, the air blowing assembly 4 continuously blows out the airflow through the air blowing nozzle 41, and cleans the unblocked debris of the chip cleaning plate 5. Lint to further enhance the cleaning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com