Sewing feeding and discharging assisting device

A technology for auxiliary feeding and receiving devices, applied in sewing equipment, sewing machine components, thin material handling, etc., can solve the problems of high quality impact, low efficiency, boring and cumbersome work content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention are described in detail below:

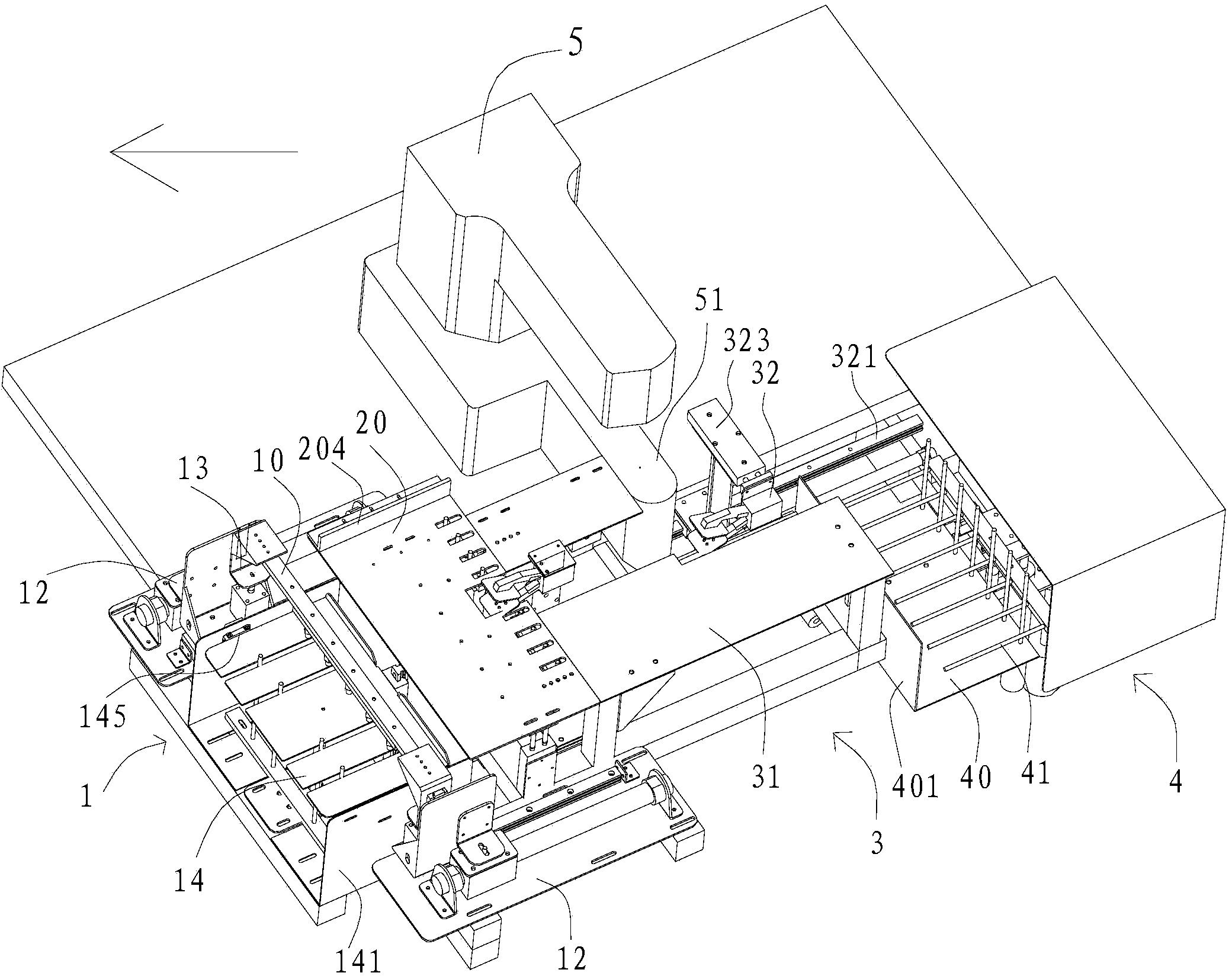

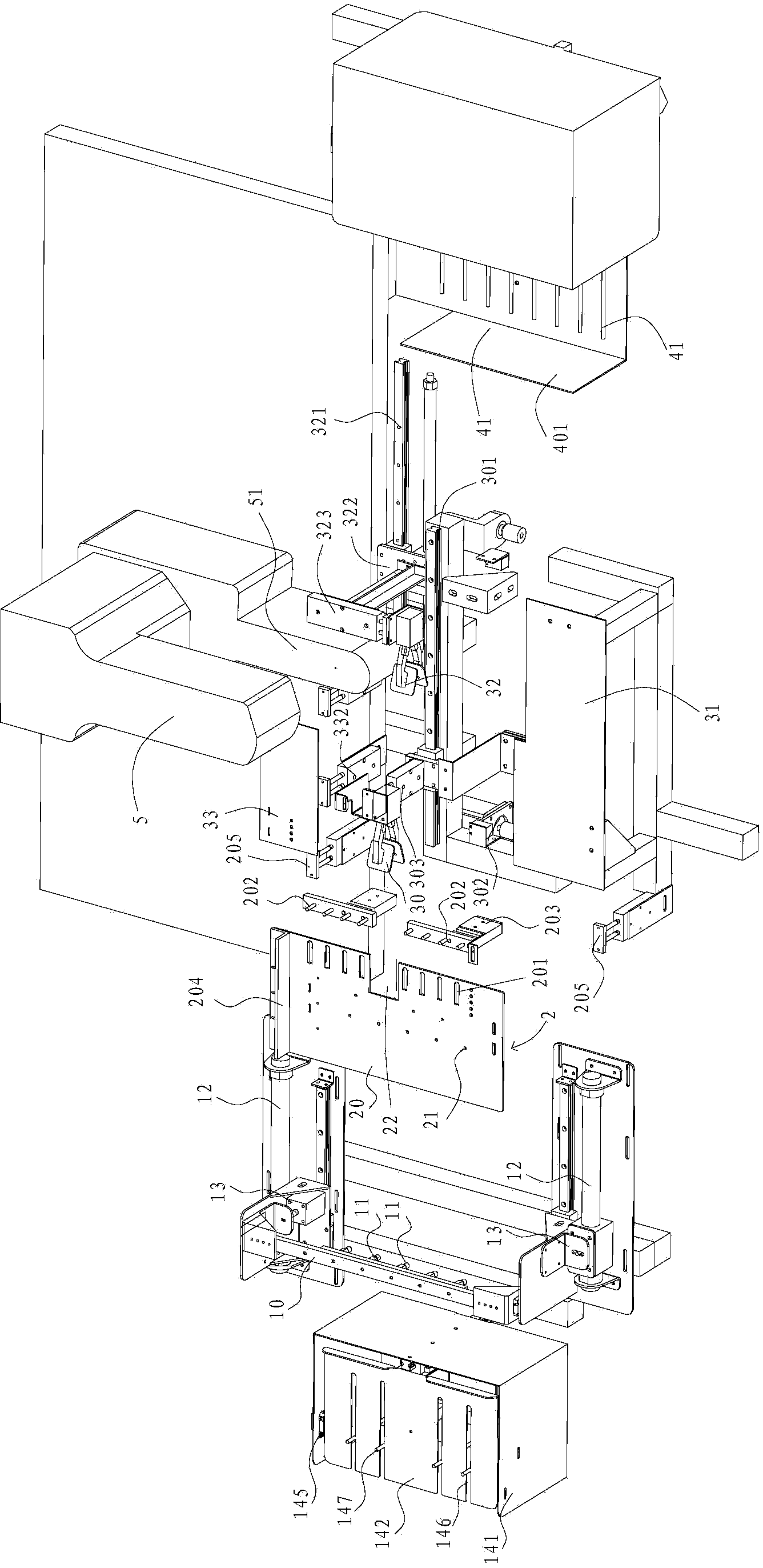

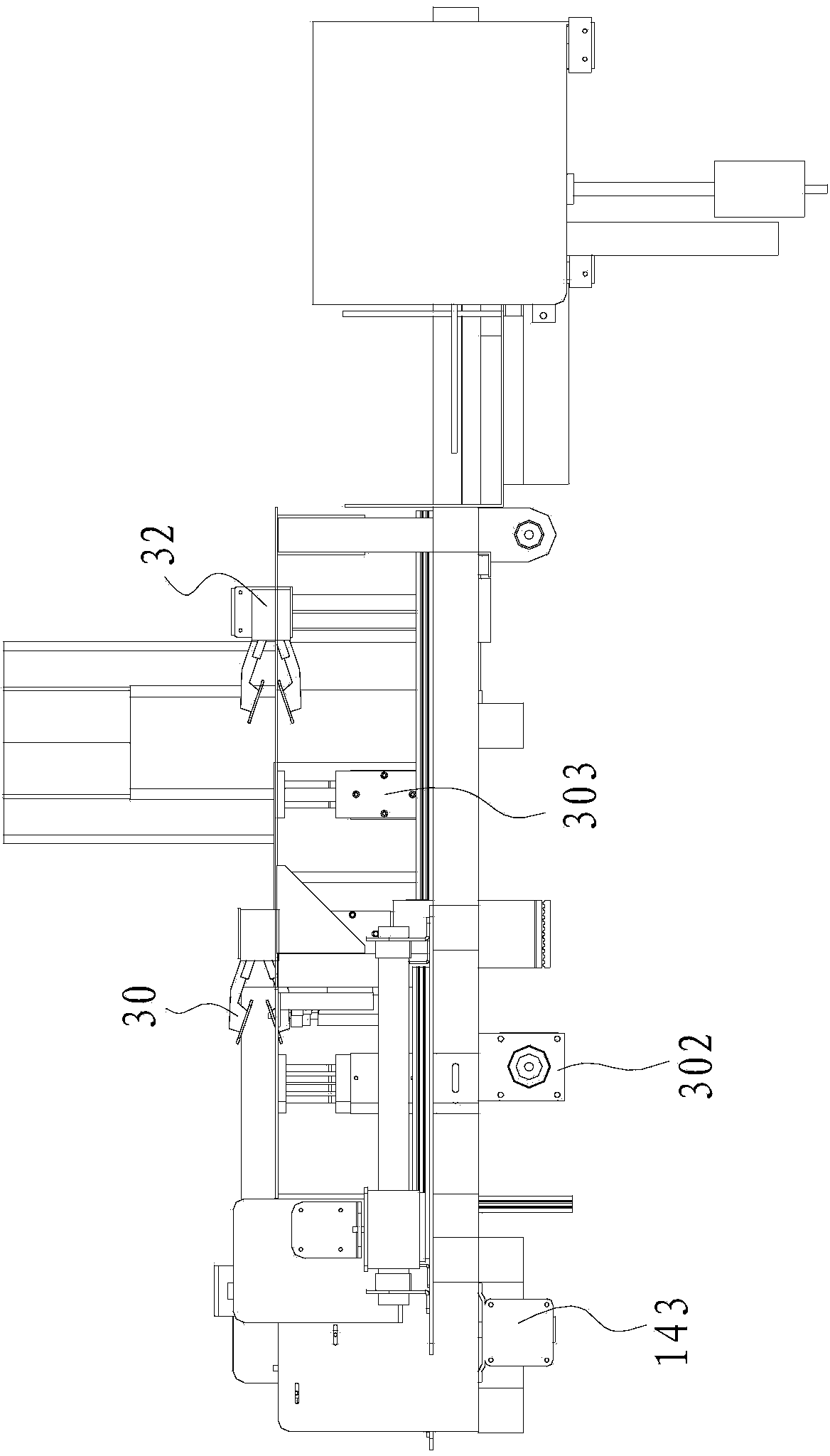

[0049] Such as figure 1 and figure 2 As shown, a sewing auxiliary feeding and receiving device is fixed with the sewing machine workbench, including:

[0050] Retrieving device 1, described retrieving device comprises cutting sheet position 14, retrieving manipulator 10, is arranged on described reclaiming manipulator 10, and with described cutting piece setting position 14 relative retrieving part 11, takes material Reciprocating mechanism 12 and retrieving lifting mechanism 13, described retrieving reciprocating mechanism 12 is distributed along the feeding direction (the present invention takes the advancing direction of the cutting piece as the front, and the position of the sewing machine is left), that is, retrieving reciprocating mechanism 12 is arranged front and rear , the reclaiming lifting mechanism 13 is slidably fixed on the retrieving reciprocating mechanism 12, and the reclaiming man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com