Method for preparing organic silicon modified plant oil

A technology for modifying vegetable oil and silicone, which is applied in the petroleum industry, lubricating compositions, base materials, etc. It can solve the problems of poor thermal stability, low temperature fluidity and hydrolysis stability, and limit the application of lubricants, so as to achieve lubrication Excellent effect, excellent lubricating performance, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

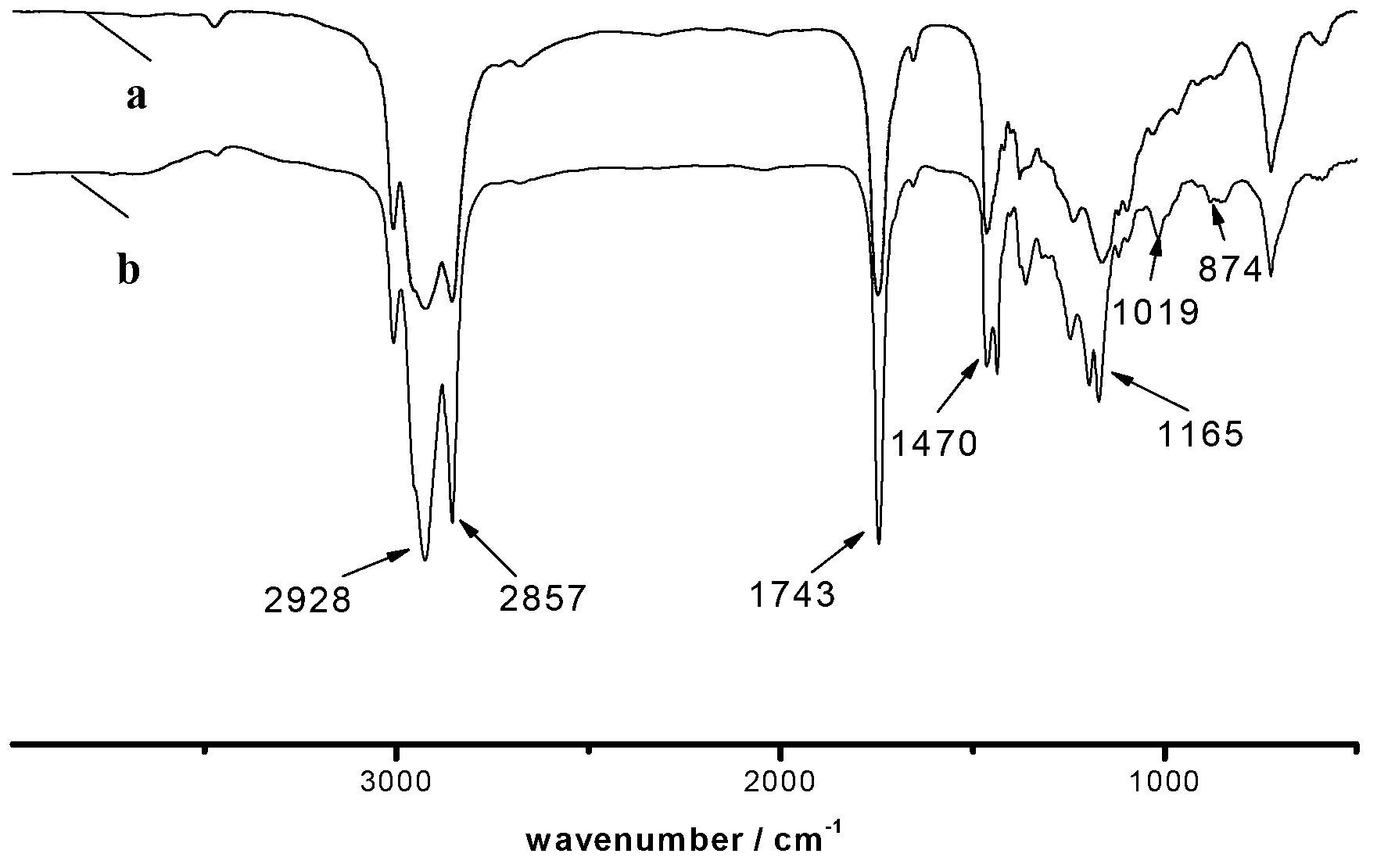

[0030] 1. Put 20g of dried rapeseed oil in a three-necked flask, then slowly drop 5.2g of potassium hydroxide methanol solution with a mass concentration of 6% into the three-necked flask to react at 60°C, and control the dripping for about 20min. After the dropwise addition was completed, the reaction was incubated for 1 h. The product is washed to neutrality, dehydrated and dried to obtain FME;

[0031] 2. At 60°C, add 28ml of hydrogen peroxide dropwise to the mixed system of 10g FME, 15ml acetic acid and 0.5g catalyst strong acid cationic resin, H 2 o 2The molar ratio with acetic acid is 1.2:1, and the dropwise addition is controlled for about 2 hours, and the temperature is kept for 4 hours after the dropwise addition is completed. The product is washed to neutrality, and dried to obtain EFME;

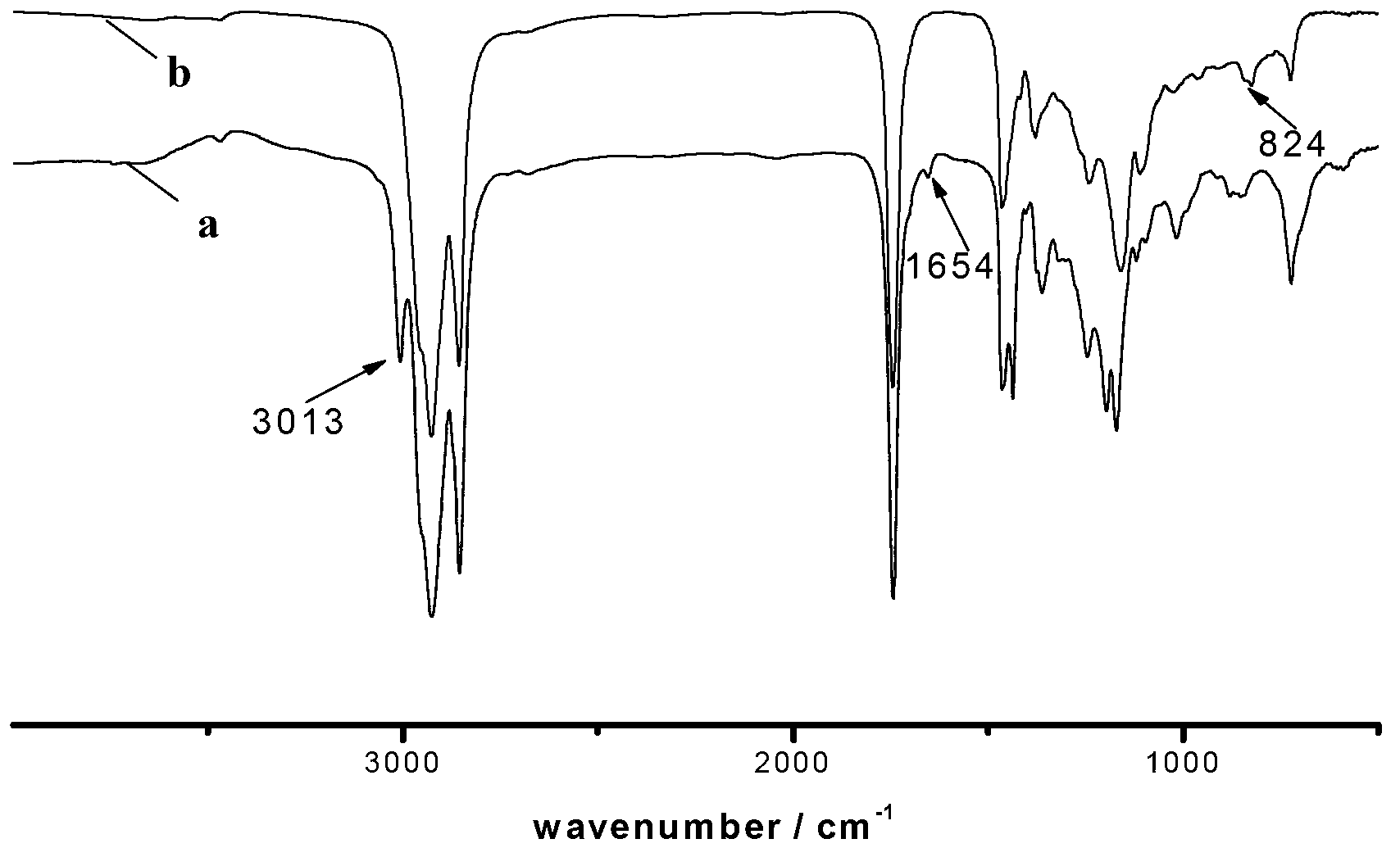

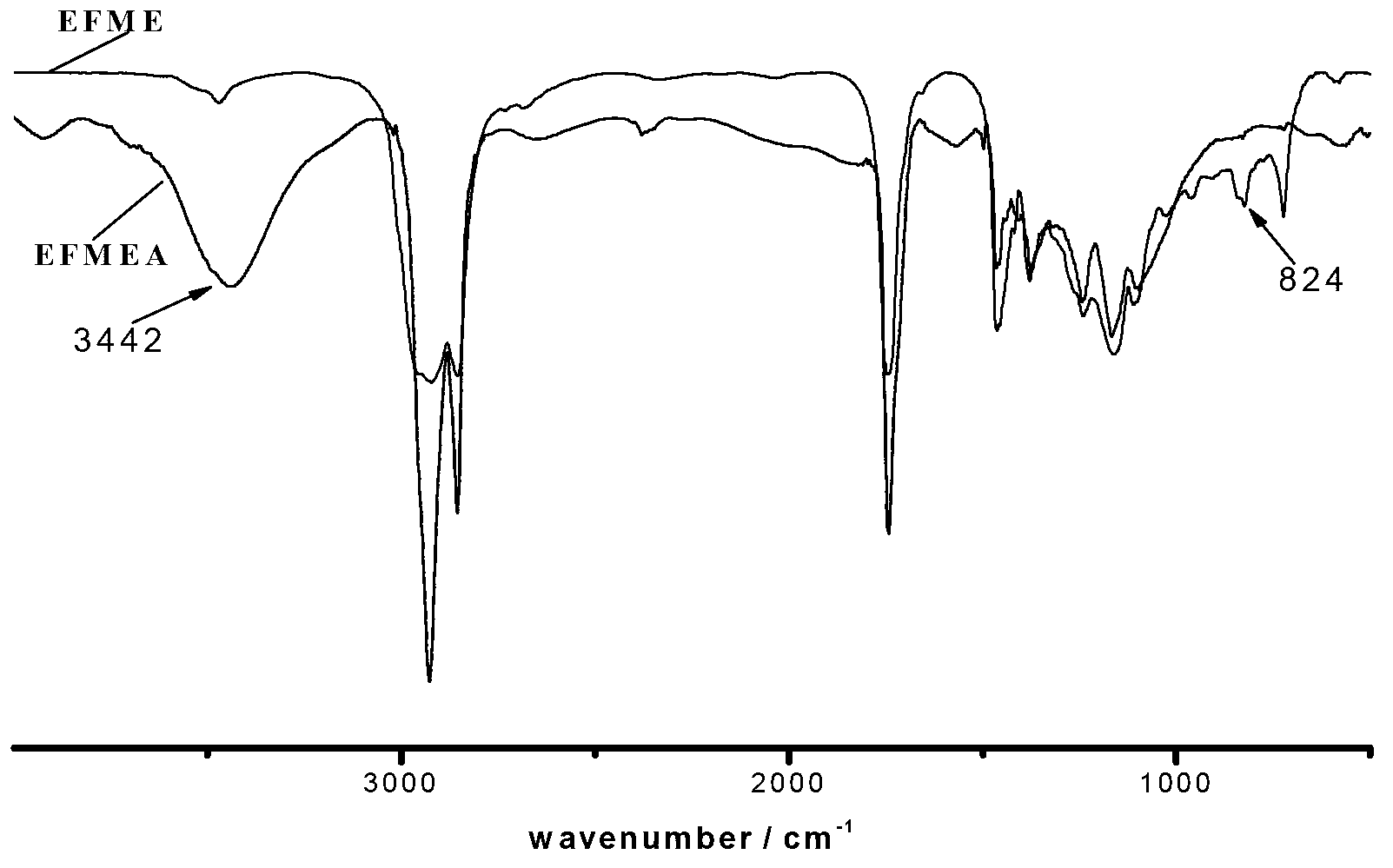

[0032] 3. At 50°C, add 4ml of acetic acid dropwise to 15g of epoxy rapeseed oil, control the dropwise addition for about 1h, and keep warm for 2h after the dropwise addition is ...

Embodiment 2

[0036] 1. Put 20g of dried rapeseed oil in a three-necked flask, then slowly drop 5.2g of potassium hydroxide methanol solution with a mass concentration of 7% into the three-necked flask to react at 60°C, and control the dripping for about 20min. After the dropwise addition was completed, the reaction was incubated for 1 h. The product is washed to neutrality, dehydrated and dried to obtain FME;

[0037] 2. At 60°C, add 28ml of hydrogen peroxide dropwise to the mixed system of 10g FME, 15ml acetic acid and 0.5g catalyst strong acid cationic resin, H 2 o 2 The molar ratio with acetic acid is 1.2:1, and the dropwise addition is controlled for about 2 hours, and the temperature is kept for 4 hours after the dropwise addition is completed. The product is washed to neutrality, and dried to obtain EFME;

[0038] 3. At 50°C, add 4ml of acetic acid dropwise to 15g of epoxy rapeseed oil, control the dropwise addition for about 1h, and keep warm for 2h after the dropwise addition is...

Embodiment 3

[0041] 1. Put 20g of dried rapeseed oil in a three-necked flask, then slowly drop 5.2g of potassium hydroxide methanol solution with a mass concentration of 8% into the three-necked flask to react at 60°C, and control the dripping for about 20min. After the dropwise addition was completed, the reaction was incubated for 1 h. The product is washed to neutrality, dehydrated and dried to obtain FME;

[0042] 2. At 60°C, add 28ml of hydrogen peroxide dropwise to the mixed system of 10g FME, 15ml acetic acid and 0.5g catalyst strong acid cationic resin, H 2 o 2 The molar ratio with acetic acid is 1.2:1, and the dropwise addition is controlled for about 2 hours, and the temperature is kept for 4 hours after the dropwise addition is completed. The product is washed to neutrality, and dried to obtain EFME;

[0043] 3. At 50°C, add 4ml of acetic acid dropwise to 15g of epoxy rapeseed oil, control the dropwise addition for about 1h, and keep warm for 2h after the dropwise addition is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com