Fluid compositions for dual clutch transmissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0105] Fluids for testing were prepared in targeted basestocks. The fully formulated fluids were prepared by adding components together in proportions shown below:

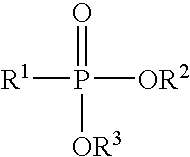

TABLE 1Antiwear / Extreme Pressure0.05-1.0%AgentsAntioxidants 0.1-0.6%Rust Inhibitors0.01-0.2%DMOP0.10-0.6%Antifoam agents0.01-0.1%Friction Modifier 0.3-1.0%Dispersant A 1-6%Seal Swell Agents 0-10%Polymethacrylate VII 3-25%Basestock 60-90%Diluent Oil 2-5%

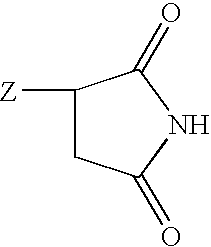

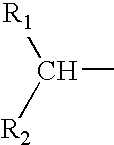

Dispersants used are succinimide dispersants that may or may not contain boron and / or phosphorus. The friction modifier was a succinimide having a C18-C24 alkenyl group. DMOP is dimethyl octadecylphosphonate. Additional friction modifiers may be used to tailor friction requirements.

[0106] Dispersant and friction modifiers provide appropriate torque capacity. Fluid compositions containing dispersant and succinimide friction modifiers have been developed to provide good friction durability. FIG. 1 is a comparison of the friction characteristics of Fluid A (Table 2) contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| durability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com