Combined flow treatment method of tin rough concentrate

A processing method and a technology of coarse concentrate, applied in chemical instruments and methods, wet separation, flotation, etc., can solve the problem of large area occupied by iron-containing materials, high labor intensity of operators, and failure to effectively recycle and other problems, to achieve the effect of difficult operation control, high production cost, and large storage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

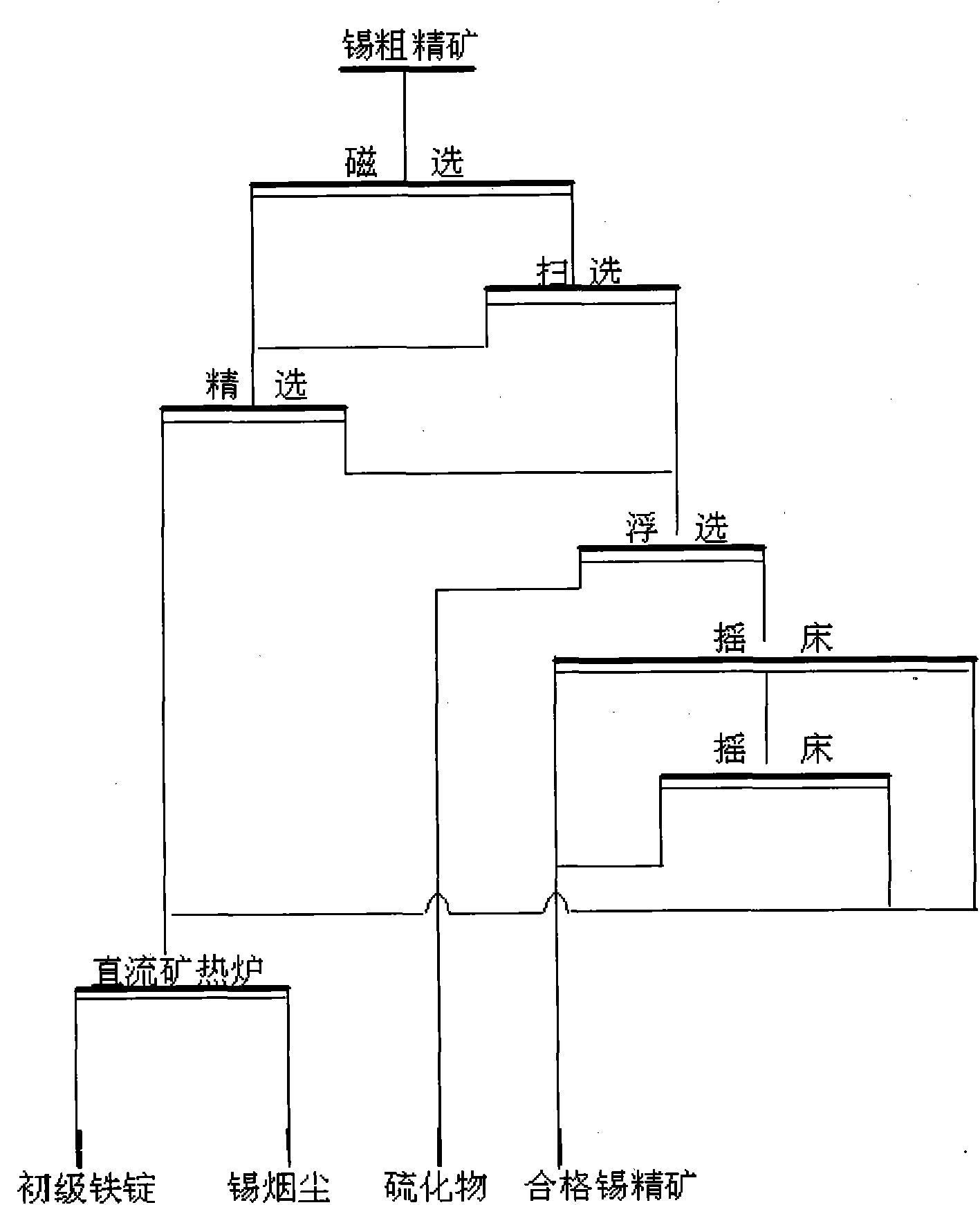

Image

Examples

Embodiment 1

[0015] Chemical composition of tin rough concentrate, Sn9.81%, Fe49.03%, S3.56%, As0.74%, SiO 2 1.40%, Al 2 o 3 11.52%, CaO2.66%, MgO0.828%. The yield of rough concentrate-200 mesh is 46.61%, and the tin metal rate is 65.33%. According to the chemical phase analysis of iron, red (brown) iron ore accounts for 88.45%, and magnetite, pyrrhotite, and pyrite account for 11.55%. The dissociation rate of monomer cassiterite is 83.61%. Minerals are dominated by metal minerals, accounting for 96.95% of the total minerals, and hematite is the main metal mineral, accounting for 49.23% of the total minerals; limonite and cassiterite are next, accounting for 30% of the total minerals respectively. 23.17% and 12.35%. Gangue minerals account for only 3.05% of the total minerals.

[0016] Process conditions and results: tin coarse concentrate is adjusted to a concentration of 25% by weight, separated by a Slon-500 vertical ring strong magnetic separator, and the magnetic field strength ...

Embodiment 2

[0018] Chemical composition of tin rough concentrate, Sn11.57%, Fe48.10%, S4.18%, As0.63%, SiO 2 1.42%, Al 2 o 3 2.50%, CaO1.26%, MgO0.50%. The yield of coarse concentrate-200 mesh is 51.99%, and the tin metal rate is 69.65%. Iron chemical phase analysis shows that red (brown) iron ore accounts for 85.50%, and magnetite, pyrrhotite, and pyrite account for 14.50%. The dissociation rate of monomer cassiterite is 85.68%. Minerals are dominated by metal minerals, accounting for 97.92% of the total minerals, and hematite is the main metal mineral, accounting for 47.36% of the total minerals; limonite and cassiterite are next, accounting for 40% of the total minerals respectively. 25.23% and 14.31%. Gangue minerals account for only 2.85% of the total minerals.

[0019] Process conditions and results: tin coarse concentrate is adjusted to a concentration of 25% by weight, separated by a Slon-500 vertical ring strong magnetic separator, and the magnetic field strength is adjuste...

Embodiment 3

[0021] Chemical composition of tin rough concentrate, Sn12.60%, Fe47.52%, S3.84%, As0.65%, SiO 2 1.023%, Al 2 o 3 4.88%, CaO2.56%, MgO0.756%. The yield of rough concentrate-200 mesh is 47.82%, and the tin metal rate is 68.13%. Iron chemical phase analysis shows that red (brown) iron ore accounts for 90.05%, and magnetite, pyrrhotite, and pyrite account for 9.95%. The dissociation rate of monomer cassiterite is 85.33%. Minerals are dominated by metal minerals, accounting for 97.26% of the total minerals, while hematite is the main metal minerals, accounting for 46.53% of the total minerals; limonite and cassiterite are next, accounting for 40% of the total minerals respectively. 24.12% and 13.31%. Gangue minerals account for only 2.75% of the total minerals.

[0022] Process conditions and results: tin coarse concentrate is adjusted to a concentration of 25% by weight, separated by a Slon-500 vertical ring strong magnetic separator, and the magnetic field strength is adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com