Secondary treatment system for steel slag and method thereof

A secondary treatment, steel slag technology, applied in the field of comprehensive utilization of resources and environmental protection, can solve the problems of large production line, complex procedures, many personnel, etc., to achieve the effect of small footprint, avoiding environmental pollution, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

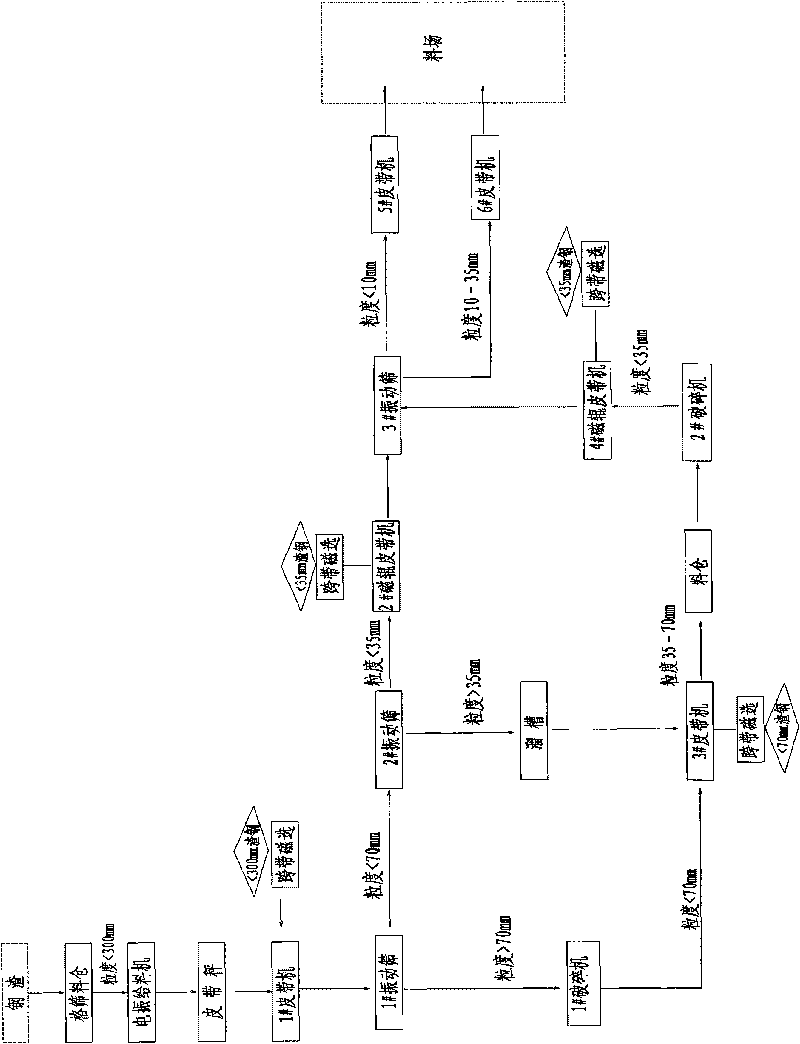

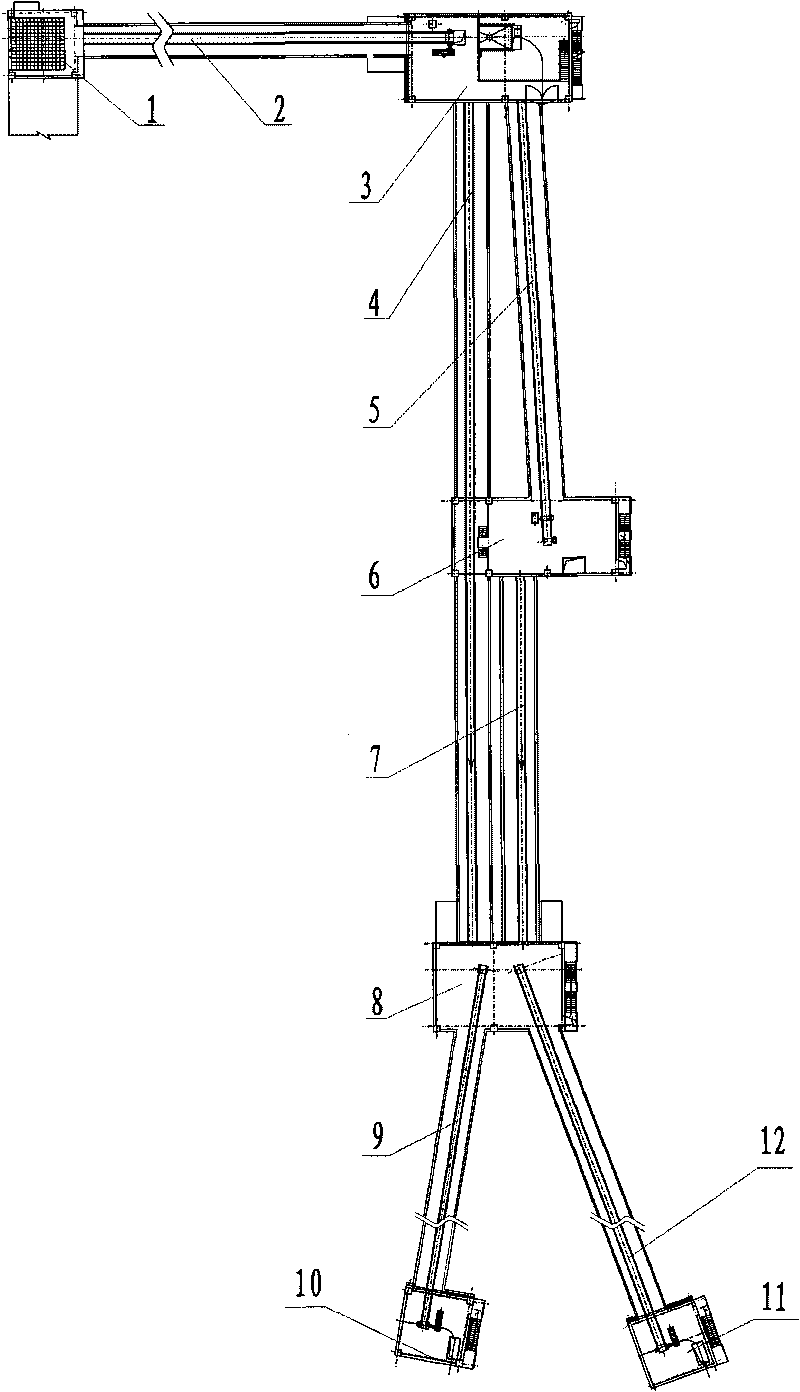

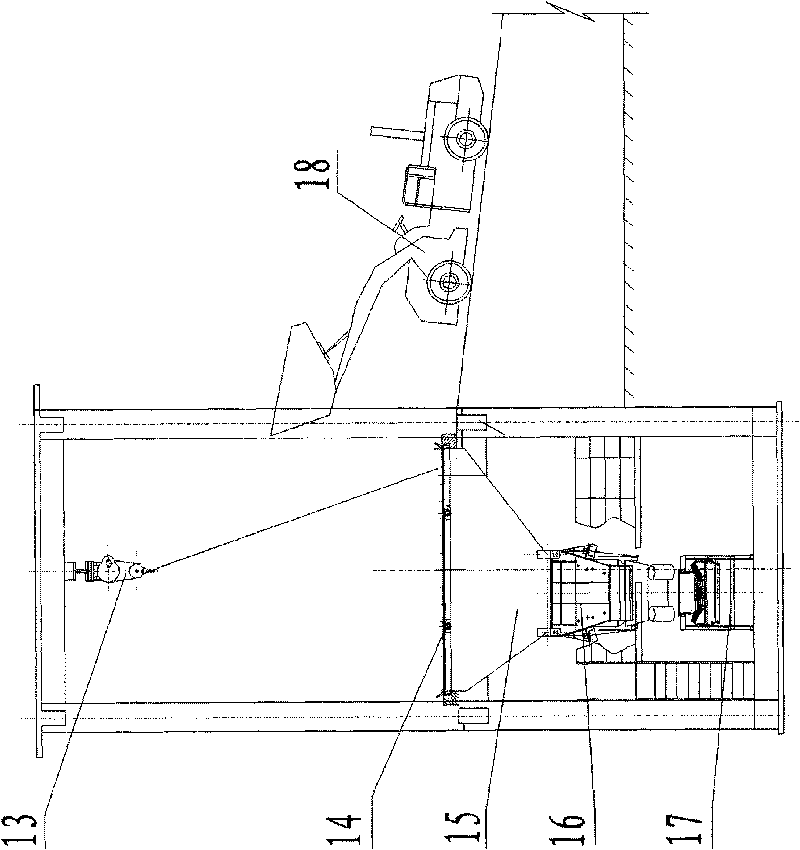

[0023] Such as figure 2 As shown, the steel slag secondary treatment process system includes a raw material room, a primary crushing and screening room, a secondary cone crushing room, a tertiary screening room, a transfer station and six belt conveyor systems. The main equipment consists of grid screen, vibrating screen, jaw crusher, cone crusher, iron remover, belt conveyor and so on. The control of main equipment is divided into manual, automatic and emergency stop buttons. The specific implementation steps are described as follows:

[0024]Before the production line starts to work, you must first check and ensure that all operating equipment is functioning normally before sending out the production line operation signal, and the signal light is on and green. The device starts to boot. The entire production line is automatically interlocked and controlled. Cameras are installed in all corridors and major equipment. In the main control room, the operator can observe the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com