Method for producing high-nickel-grade nickel-iron powder by laterite-nickel ore autocatalytic reduction

A technology for laterite nickel ore and nickel-iron powder, which is applied in the field of comprehensive utilization of mineral resources, can solve the problems of increased production cost, waste of resources, unexplained tailings treatment in roughing and selection operations, etc., so as to reduce emissions and reduce consumption. , The effect of process environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

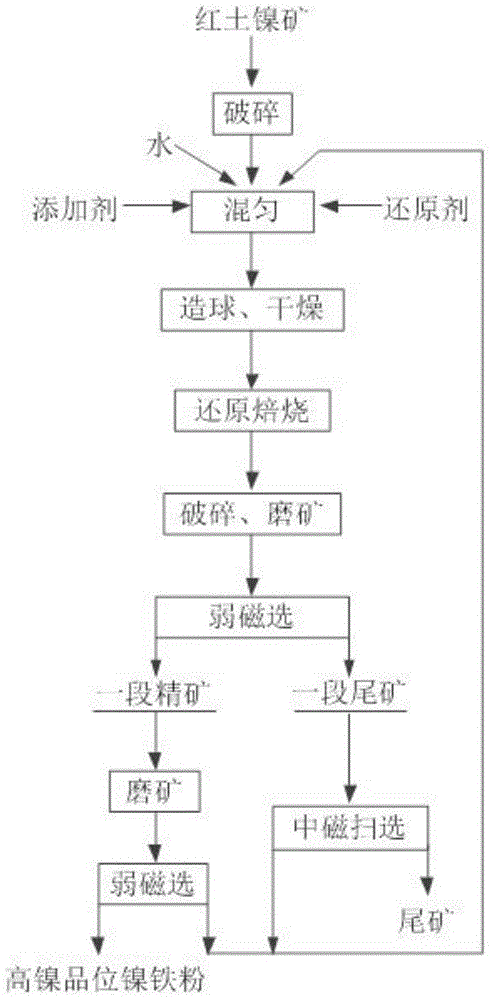

Image

Examples

Embodiment 1

[0016] A lateritic nickel ore contains 34.69% iron and 1.49% nickel. The raw ore is crushed to -2mm to account for 100%, add 5% reducing agent coal, add 10% sodium sulfate, add about 11% water and mix well, press the ball on the double-roller briquetting machine, and the obtained carbon-containing pellets are anti-fall The average strength is 7 times / piece, and the compressive strength is 48N / piece; the dry ball drop strength after drying is 9 times / piece, and the compressive strength is 360N / piece. Then it was reduced and calcined at 1200°C for 50 min in a muffle furnace. After the roasted ore is cooled, it is first crushed to -2mm, and then it is ground and sorted in stages. The first stage grinding concentration is 68%, and the fineness is -0.074mm, accounting for 65%. The second stage grinding concentration is 62%, and the fineness is - 0.074mm accounts for 95%, and the strength of the two magnetic separation fields is 89.6kA / m. Finally, the nickel grade is 9.82%, the ni...

Embodiment 2

[0019] A lateritic nickel ore contains 26.68% iron and 1.46% nickel. The raw ore is crushed to -1mm to account for 100%, add 5% reducing agent coal, use 5% lime and 10% sodium sulfate as a mixed desulfurizer, add 10% water, mix and briquette on a double-roller briquetting machine. The average drop strength of the obtained carbon-containing pellet green balls is 7 times / piece, and the compressive strength is 50N / piece; after the pellets are dried, the drop strength is 9 times / piece, and the compressive strength is 156N / piece. Put the carbon-containing pellets in a muffle furnace for reduction roasting at 1150°C for 50 minutes; after the roasted ore is cooled, it is first broken to -2mm, and then it is ground and sorted in stages. The concentration of the first stage of grinding is 65%, and the fineness is -0.074 mm accounts for 65%, the second stage grinding concentration is 60%, the fineness is -0.074mm and accounts for 95%, and the magnetic separation field strength of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com