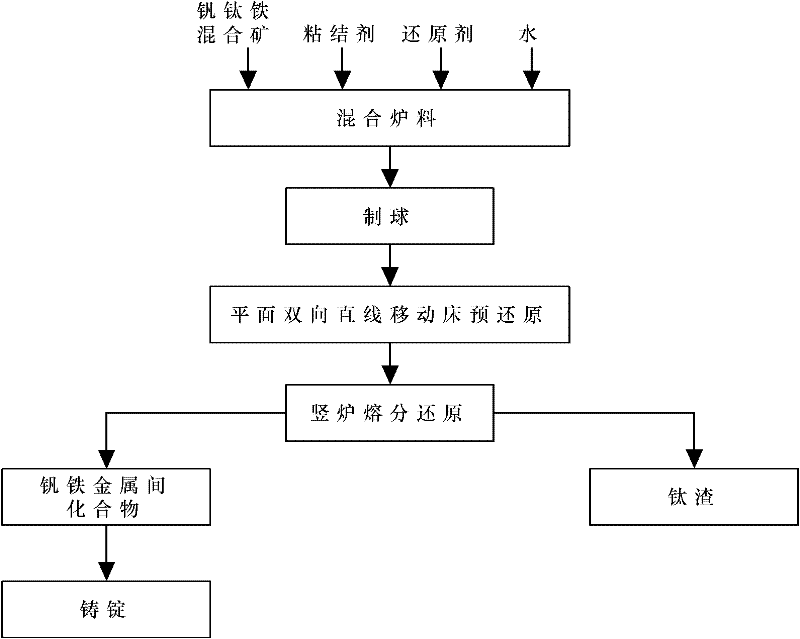

Method for preparing vanadium-iron intermetallic compound and titanium slag using linear moving bed pre-reduction-shaft furnace melting process

A technology of intermetallic compounds and linear movement, applied in shaft furnaces, furnaces, furnace types, etc., can solve problems such as difficult large-scale industrial applications, affecting normal operation of equipment, and low production efficiency, achieving high production efficiency, social benefits and Significant economic benefits and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

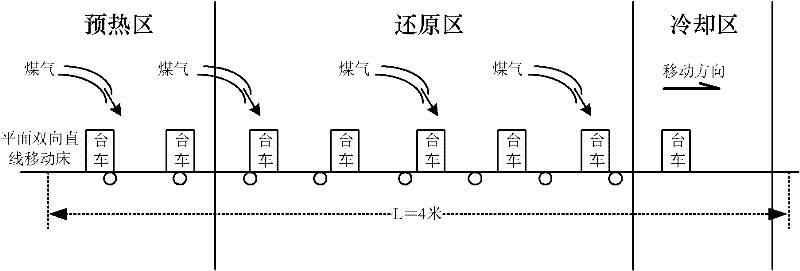

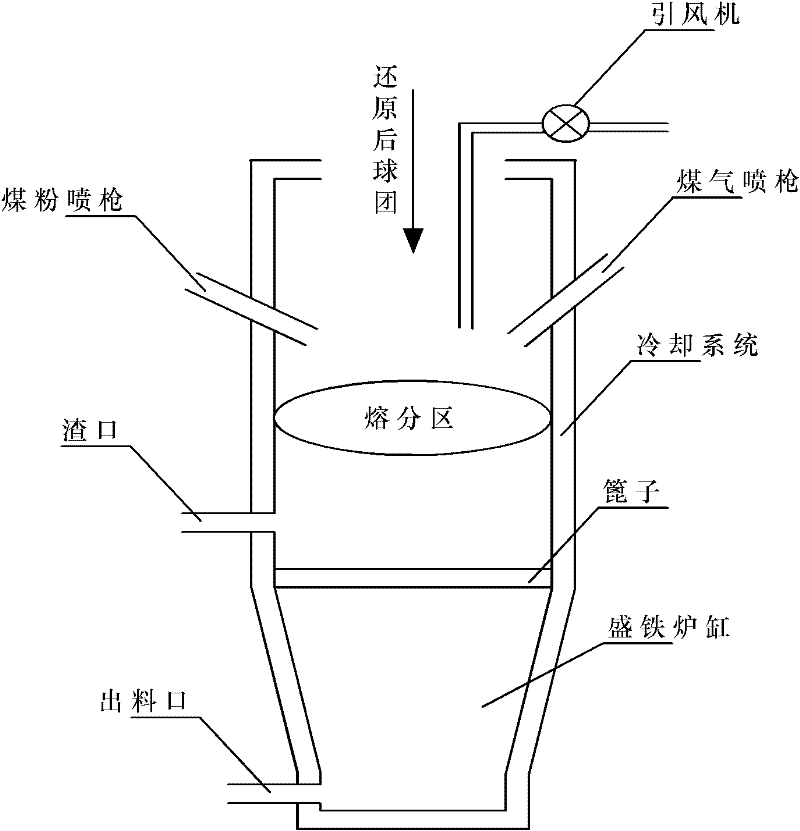

Method used

Image

Examples

Embodiment 1

[0067] Step 1: Mixing

[0068] Mix vanadium-titanium iron mixed ore, polyanionic cellulose PAC (binder), anthracite (reducing agent) and tap water in a mechanical agitation ball mill (ZJM-20 periodic mechanical agitation ball mill) for 60 minutes to obtain a mixed charge;

[0069] Dosage: Add 5 kg of binder, 100 kg of reducing agent and 100 kg of water to 1000 kg of vanadium-titanium-iron mixed ore.

[0070] In the present invention, the composition of vanadium-titanium-iron mixed ore is (mass percentage): total iron (TFe) 50.28%, titanium dioxide (TiO 2 )20.64%, vanadium pentoxide (V 2 o 5 )0.42%, SiO 2 2.2%, MgO2.58%, CaO0.61%. see image 3 The XRD analysis figure shown.

[0071] Step Two: Make the Ball

[0072] The mixed charge is pressed into pellets (diameter 4 cm, thickness 3 cm) on a pellet forming machine (equipment model QT300), with a pressure of 50 MPa; pellet drop strength: 0.7 meters secondary without rupture; average pellet resistance Compressive strength...

Embodiment 2

[0098] Step 1: Mixing

[0099] Mix vanadium-titanium-iron mixed ore, carboxymethyl cellulose (bonding agent), charcoal (reducing agent) and tap water in a mechanically agitated ball mill for 30 minutes to obtain a mixed charge; the charcoal has a fixed carbon content of 96%, a particle size of 1mm.

[0100] Dosage: Add 3 kg of binder, 150 kg of reducing agent and 100 kg of water to 1000 kg of vanadium-titanium-iron mixed ore.

[0101] In the present invention, the composition of vanadium-titanium-iron mixed ore is (mass percentage): total iron (TFe) 50.28%, titanium dioxide (TiO 2 )20.64%, vanadium pentoxide (V 2 o 5 )0.42%, SiO 2 2.2%, MgO2.58%, CaO0.61%. see image 3 The XRD analysis figure shown.

[0102] Step Two: Make the Ball

[0103] The mixed charge is pressed into pellets with a diameter of 4 cm and a thickness of 3 cm on a pelletizing machine, with a pressure of 30 MPa; the pellet drop strength: 0.7 meters without breaking for the second time; the average com...

Embodiment 3

[0112] Step 1: Mixing

[0113] Mix vanadium-titanium-iron mixed ore, sodium humate (binder), petroleum coke (reducing agent) and clear mountain spring water in a mechanical stirring ball mill for 40 minutes to obtain a mixed charge;

[0114] Dosage: Add 4 kg of binder, 120 kg of reducing agent and 50 kg of water to 1000 kg of vanadium-titanium-iron mixed ore.

[0115] In the present invention, the composition of vanadium-titanium-iron mixed ore is (mass percentage): total iron (TFe) 50.28%, titanium dioxide (TiO 2 )20.64%, vanadium pentoxide (V 2 o 5 )0.42%, SiO 2 2.2%, MgO2.58%, CaO0.61%. see image 3 The XRD analysis figure shown.

[0116] Step Two: Make the Ball

[0117] The mixed charge is pressed into pellets with a diameter of 4 cm and a thickness of 3 cm on a pelletizing machine, with a pressure of 60 MPa; pellet drop strength: 0.7 meters without breaking for two times; average compressive strength of pellets: 1304.77 N / piece (measure 60 pellets in total);

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com