Three-step metal reducing method

A three-step method, metal technology, applied in iron oxide "three-step method" reduction of metal iron, metal oxide smelting reduction metal field, can solve the problem of low utilization rate of gas, poor bonding and discharging, pre-reduction Low speed and other problems, to achieve the effect of less impurities and non-metallic inclusions, good working conditions, and simple production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

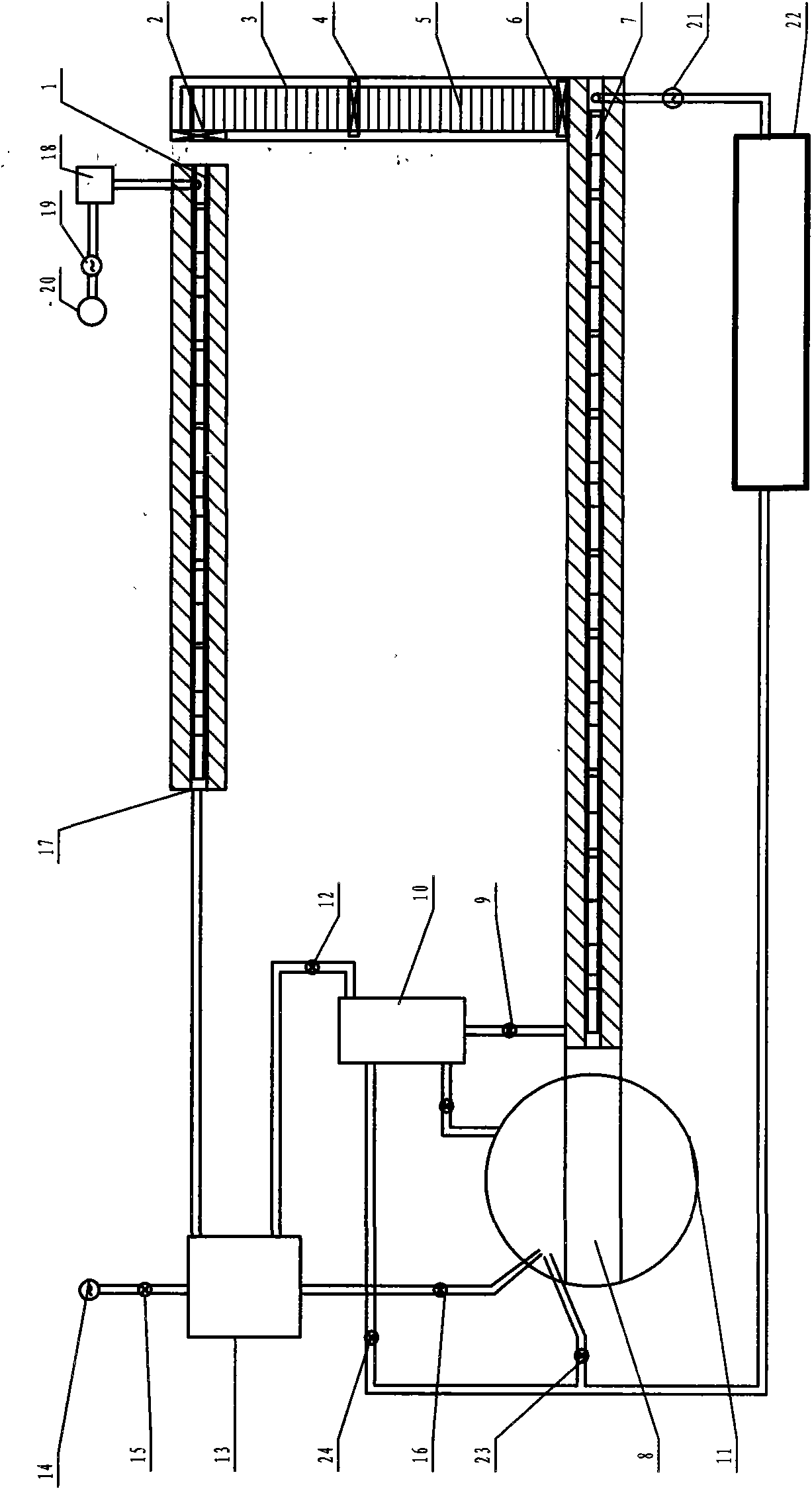

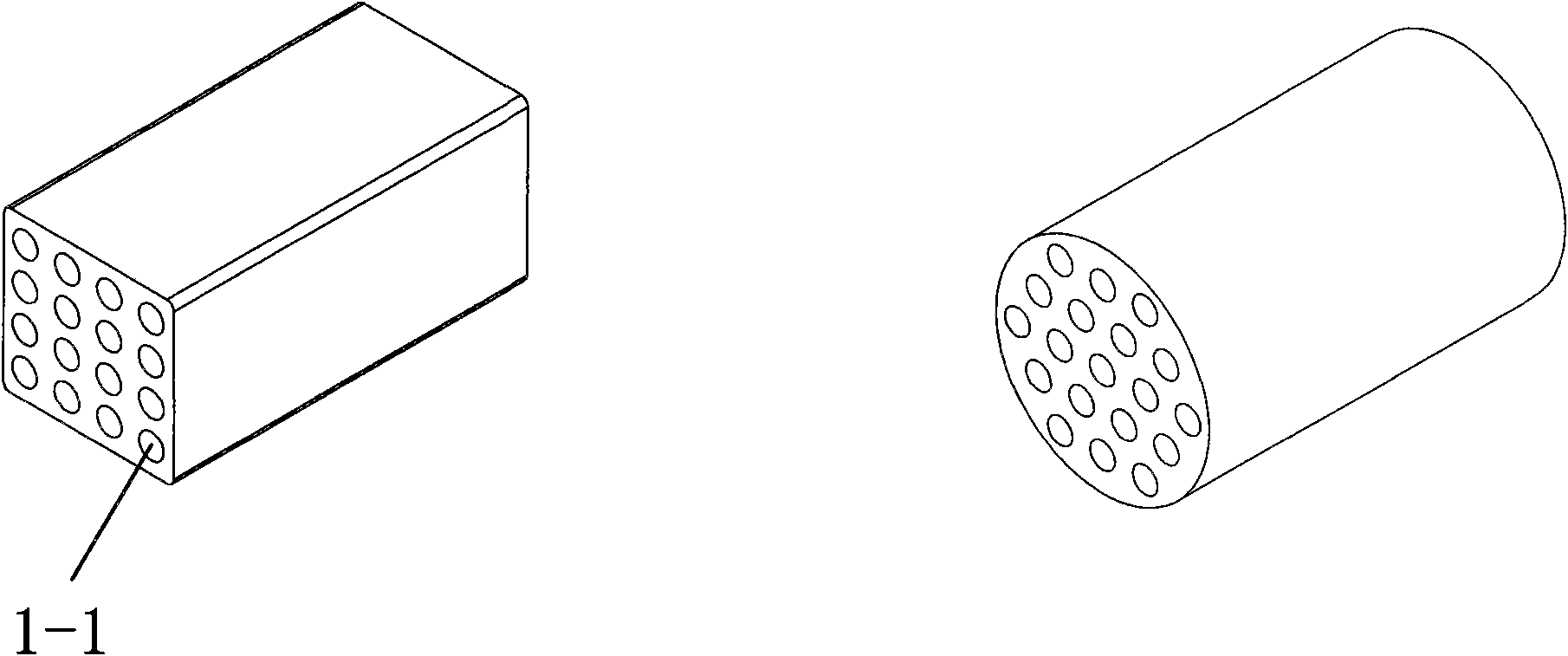

[0034]The reduction furnace can be a shaft furnace, a roller furnace, a pusher furnace, a bell furnace, a coke oven, etc. The reduction furnace is a roller furnace as an example. The molded object is placed on the bottom plate made of metal or non-metallic materials, the bottom plate is placed on the roller table, and the roller table moves the bottom plate forward through mechanical transmission. The roller shaft is made of non-metal or heat-resistant metal. The bottom plate and the roller shaft must have High-temperature strength, depending on the composition of the molded product, the base plate may not be used, and the molded product may be placed directly on the roller table. The roller table furnace adopts various seals to isolate air and oxygen. The shape of the molded product is as figure 2 Rectangular or cylindrical honeycomb shapes shown. Roller type reduction furnace device such as figure 1 As shown, the molded product is dried on the drying kiln 1 with low-tempe...

example 2

[0036] Such as Figure 6 As shown, it is similar to Example 1, except that a bath heating furnace 25 and a smelting furnace 26 are adjusted. After the high-temperature heat exchange device 10 is heat-exchanged, the precipitated gas through the valve 9 enters the molten iron molten pool from the bottom of the molten pool heating furnace 25 or the nozzle on the side of the furnace or the breathable refractory device, and enters the molten iron pool after being heated to a high temperature through the molten iron molten pool. In the associated reducing furnace 7, it is used as a heat carrier, reducing agent or protective gas to reduce the molded product, and the purpose of increasing the heating of the molten pool is to reduce the burden on the high-temperature heat exchange device 10, so that it can be processed at a lower temperature. The precipitated gas is preheated, and then the precipitated gas is heated by the molten pool heating furnace 25, so that the precipitated gas is...

example 3

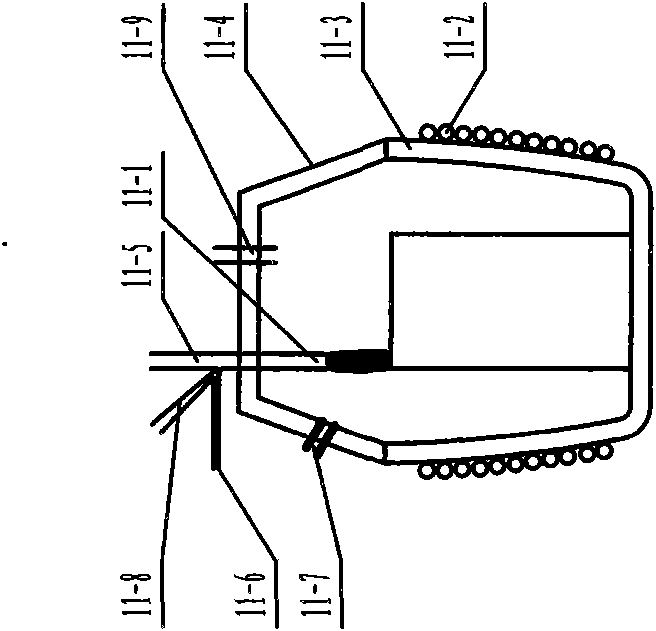

[0038] There are many external heating reduction furnaces using the three-step method, which can be shaft furnaces, roller furnaces, pusher furnaces, continuous heating furnaces, bell furnaces and coke ovens. In this example, an external heating reduction furnace similar to a bell furnace is used as a reduction furnace system. See Figure 7 , Figure 8 , using the molded product as figure 2As shown in the honeycomb molding, if its length is insufficient, it can be stacked with holes, or it can be block, spherical, rectangular or cylindrical molding, placed on the base 29-11 of the reduction furnace, and there is a refractory insulation material on the base 29-10, there are many connecting passages 29-12 at right angles on the refractory material as a whole, through the fan 29-15, the precipitated gas enters the right-angled connecting passage 29-12 through the honeycomb passage of the molding and then flows out along the metal heat-resistant material. (or non-metal refract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com