Full-screen curved-plane evaporation mobile phone glass film and production process thereof

A glass film and curved surface technology, which is applied in the field of full-screen curved mobile phone glass film deposition and its production process, can solve problems such as eye-sickness, inconvenience to carry, and fast power consumption of mobile phone screens, and achieve good visual effects and no obtrusive effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

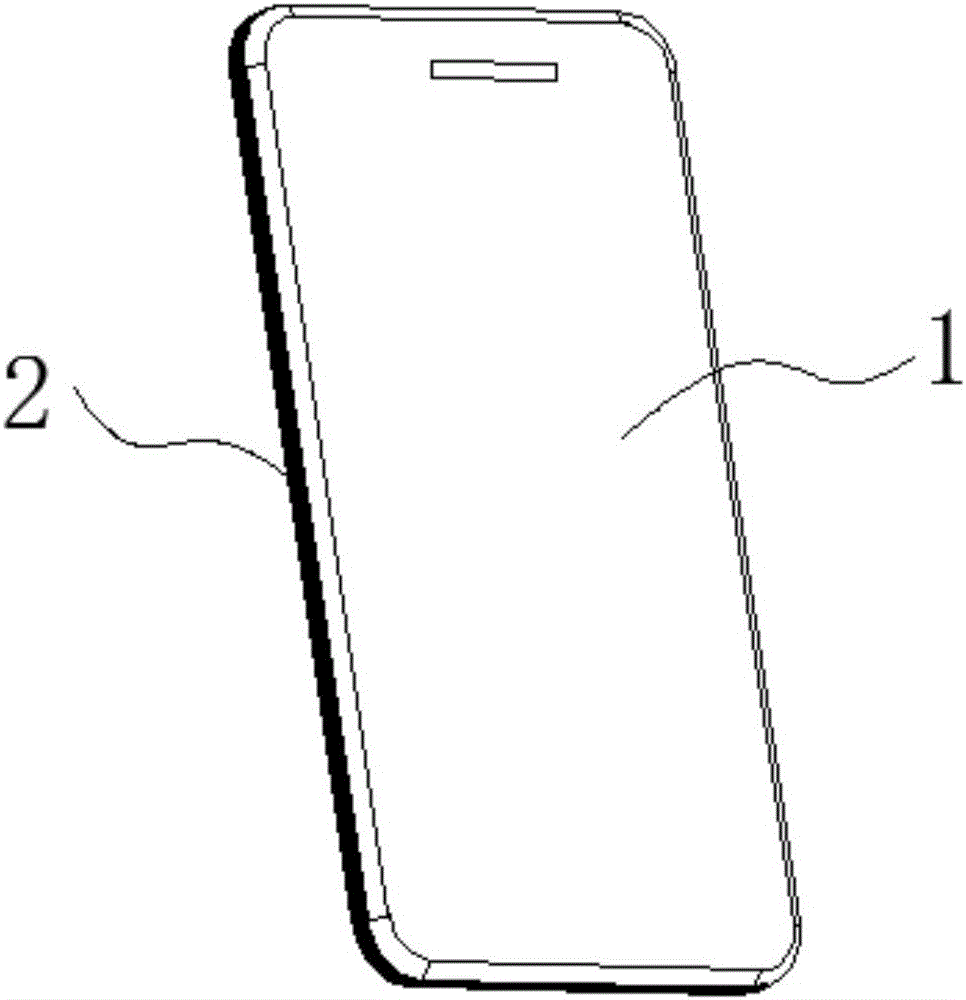

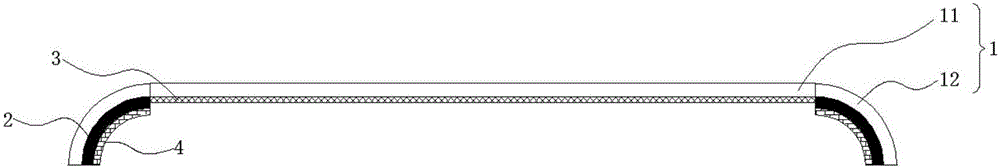

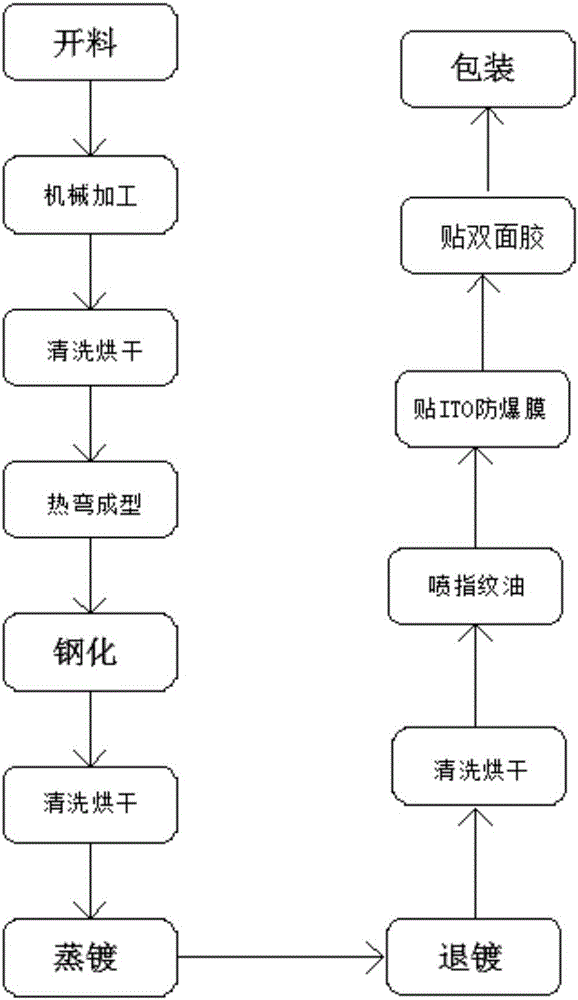

[0016] Such as figure 1 and figure 2 As shown, a full-screen curved mobile phone glass film is used for a full-screen borderless curved mobile phone, including a tempered glass layer 1 and an alloy layer 2. The tempered glass layer 1 is divided into a central transparent part 11 and a curved part 12 on the four sides. There is an ITO explosion-proof layer 3 under the transparent part 11, and the ITO explosion-proof layer 3 effectively protects the screen of the mobile phone, is explosion-proof and drop-proof, and the curved part 12 matches the curved surface of the full-screen mobile phone frame. The thickness of the alloy layer 2 is 0.3-0.5 μm. The color of the alloy layer 2 is similar to that of the mobile phone shell. The alloy layer 2 covers the black edge of the curved surface of the mobile phone screen frame, which is beautiful and generous, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com