Flame-retardant antistatic high-strength thermoplastic composite material and its preparation method

A composite material and thermoplastic technology, applied in the field of polymer modification, can solve problems such as large smoke generation, secondary pollution, and affecting material quality, and achieve high tensile and bending strength, high impact resistance, and antistatic properties significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

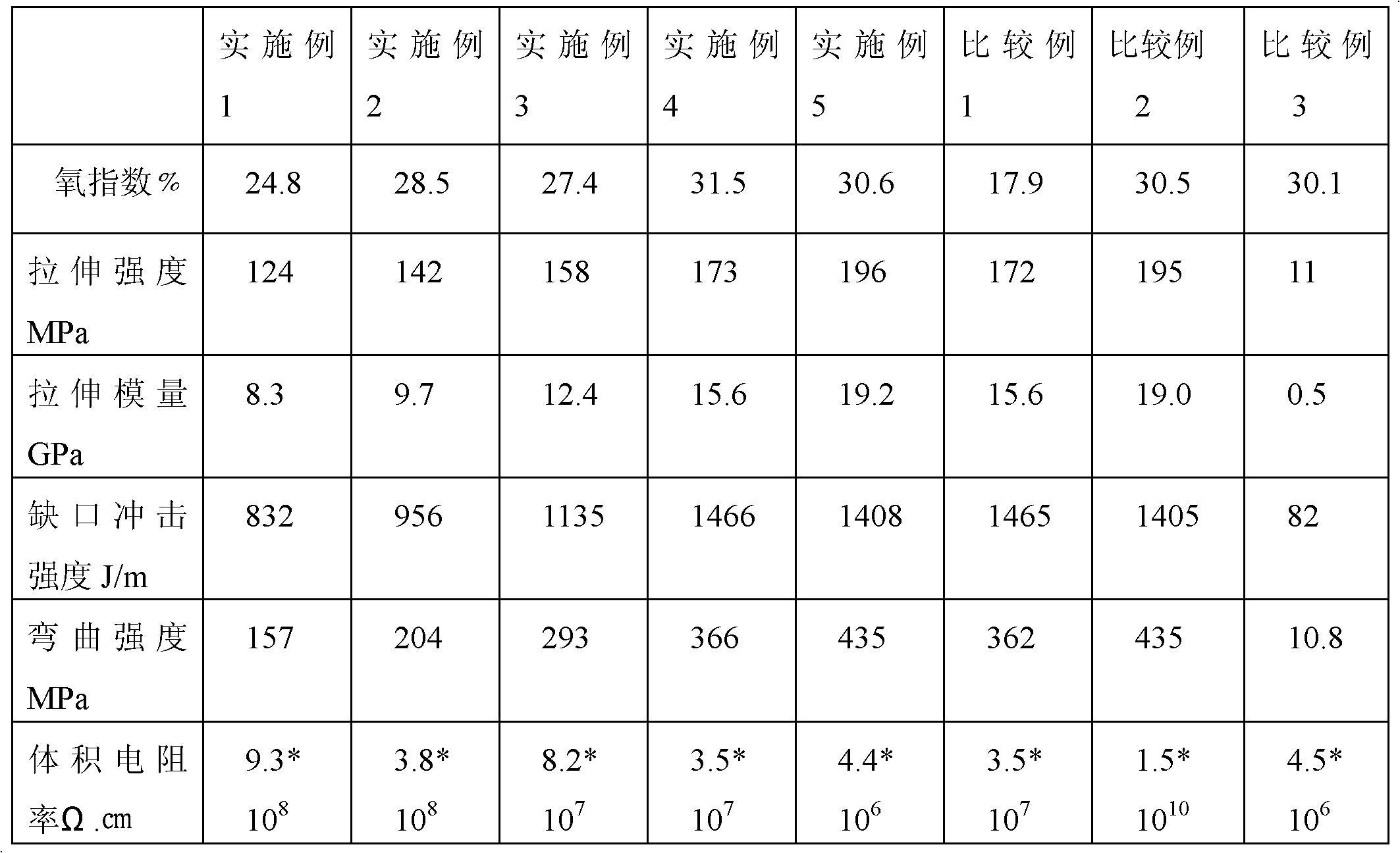

Examples

Embodiment 1

[0032] First, 100 parts of polypropylene resin powder, 5 parts of ammonium polyphosphate coated with epoxy resin, 4 parts of melamine cyanurate, 2 parts of antimony trioxide, 0.5 part of bis(β-hydroxyethyl) stearylamine, antimony 2 parts of oxygen agent DLTP and 4 parts of antioxidant 1010 compound type antioxidant, 30 parts of talcum powders, 18 parts of maleic anhydride grafted polypropylene are all prepared by weight, and then placed in a 1200r / min Pre-mix in a high-speed mixer for 10 minutes at a temperature of 80-100°C; then place the mixed material in a high-voltage electrostatic fluidized bed, and pass 55 parts of glass fibers continuously through the fluidized bed to adjust the electrostatic voltage of the fluidized bed Adjust the amount of glass fiber adsorbing resin to keep the weight of polypropylene resin at 100 parts; the glass fiber adsorbed with resin continuously passes through the oven and high-temperature die, and then passes through the mold, and is made at 1...

Embodiment 2

[0034] First, 90 parts of polypropylene resin powder, 7 parts of ammonium polyphosphate coated with epoxy resin, 5 parts of melamine cyanurate, 3 parts of antimony trioxide, 0.8 parts of bis(β-hydroxyethyl) stearylamine, antimony 3 parts of oxygen agent DLTP and composite antioxidant of 1010 5 parts of antioxidants, 15 parts of maleic anhydride grafted polypropylenes complete the raw materials by weight, and then place them in a high-speed mixer at 1400r / min for pre-treatment. Mix for 8 minutes at a temperature of 80-100°C; then place the mixed material in a high-voltage electrostatic fluidized bed, pass 75 parts of glass fibers through the fluidized bed continuously, and adjust the electrostatic voltage of the fluidized bed to adjust the glass fiber adsorption The amount of resin is to keep the weight of polypropylene resin at 100 parts; the glass fiber adsorbed with resin passes continuously through the oven and high-temperature die, and then passes through the mold to make a...

Embodiment 3

[0036]First, 100 parts of polypropylene resin powder, 8 parts of epoxy resin-coated ammonium polyphosphate, 6 parts of melamine cyanurate, 1.2 parts of bis(β-hydroxyethyl) stearylamine, 3 parts of antioxidant DLTP and anti-oxidant Composite antioxidant composed of 2 parts of oxygen agent 1010, 50 parts of talcum powder, 20 parts of maleic anhydride grafted polypropylene, complete the raw materials by weight, and then place them in a high-speed mixer at 1500r / min for pre-mixing for 12min , the temperature is 80-100°C; then the mixed material is placed in a high-voltage electrostatic fluidized bed, and 100 parts of glass fibers are continuously passed through the fluidized bed, and the electrostatic voltage of the fluidized bed is adjusted to adjust the glass fiber adsorption resin. amount, so that the weight of the polypropylene resin is kept at 100 parts; the glass fiber adsorbed with the resin passes through the oven and the high-temperature die continuously, and then passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com