Ultra-high performance concrete with compressive strength of 300MPa or more and preparation method

A technology with ultra-high performance and compressive strength, applied in the field of building materials, can solve the problems that hinder the popularization and application of ultra-high performance concrete, poor construction difficulty, low strength, etc., and achieve excellent work performance, improve compactness, and improve work performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

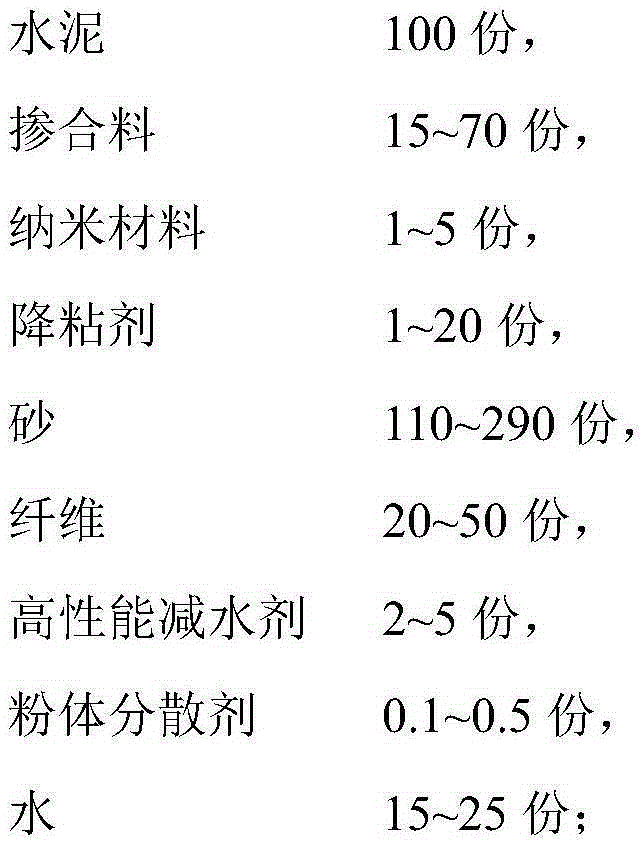

Method used

Image

Examples

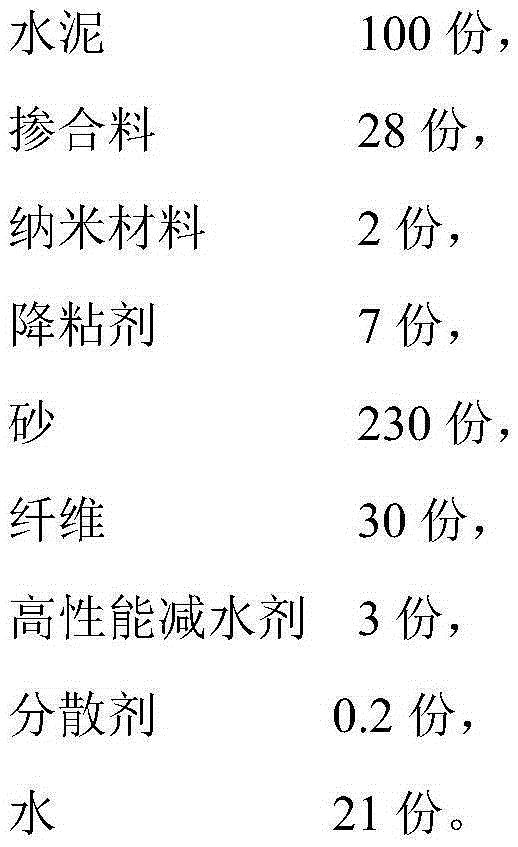

Embodiment 1

[0043] In Example 1, the viscosity reducer is a mineral viscosity reducer; the sand is a mixture of quartz sand and corundum in a mass ratio of 20:80.

Embodiment 2

[0044] In Example 2, the viscosity reducer is an organic-inorganic composite liquid viscosity reducer; the sand is a mixture of quartz sand and corundum in a mass ratio of 20:80.

Embodiment 3

[0045] In Example 3, the viscosity reducer is a mineral viscosity reducer; the sand is a mixture of quartz sand and corundum in a mass ratio of 20:80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com