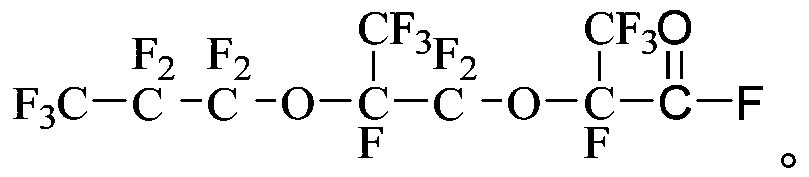

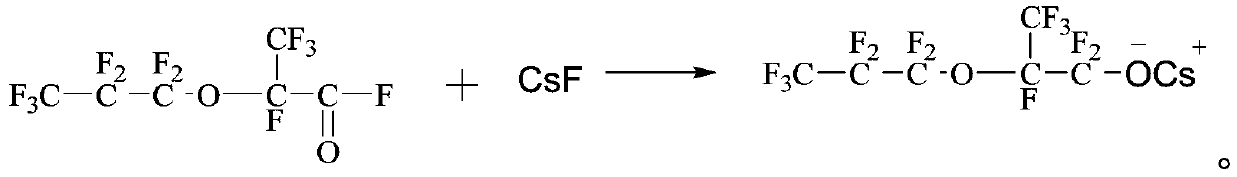

Method for preparing hexafluoropropylene oxide trimer

A technology of hexafluoropropylene oxide dimer alcohol and hexafluoropropylene oxide, which is applied in the field of preparing hexafluoropropylene oxide trimer, and can solve the problem of insufficient meeting the needs of industrialized production, dispersion of product polymerization degree, and insufficient selectivity. Advanced problems, to achieve the effect of suitable for large-scale industrial production, high selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Add 200ml of tetraethylene glycol dimethyl ether, 37.1g of potassium alkoxide of hexafluoropropylene oxide dimer, 11.6g of potassium fluoride and 5g of trifluoroacetic acid into a 2L reaction kettle with a condensing jacket. Control the temperature in the kettle; feed 1 kg of hexafluoropropylene oxide monomer into the reaction kettle through a metering device, the feeding rate is controlled at 400 sccm, pump the reaction kettle to -1 bar, and maintain the temperature in the kettle at -15°C. After the completion of feeding, the reaction was stirred and kept stirring for 3h.

[0055] After the reaction, the crude product was taken out from the reactor, and the product in the lower layer was removed after liquid separation, and filtered to obtain 0.998 kg of the crude product, and the calculated conversion rate of hexafluoropropylene oxide was 99.8%. Take a small amount of the obtained crude product, add excess methanol for methyl esterification, stir at room temperature f...

Embodiment 2

[0057] Add 200ml of diethylene glycol dimethyl ether, 35.5g of sodium hexafluoropropylene oxide dimer alkoxide, 12.6g of sodium fluoride and 5g of trifluoroacetic acid into a 2L reaction kettle with a condensing jacket. Control the temperature in the kettle; feed 1 kg of hexafluoropropylene oxide monomer into the reaction kettle through a metering device, the feeding rate is controlled at 400 sccm, pump the reaction kettle to -1 bar, and maintain the temperature in the kettle at -15°C. After the completion of feeding, the reaction was stirred and kept stirring for 3h.

[0058] After the reaction, the crude product was taken out from the reaction kettle, and the product in the lower layer was removed after liquid separation, and filtered to obtain 0.991 kg of the crude product, and the conversion rate of hexafluoropropylene oxide was calculated to be 99.1%. Take a small amount of the obtained crude product, add excess methanol for methyl esterification, stir at room temperature...

Embodiment 3

[0060] Add 200ml of acetonitrile, 37.1g of potassium alkoxide of hexafluoropropylene oxide dimer, 11.6g of potassium fluoride and 10g of perfluorohexanoic acid into a 2L reaction kettle with a condensation jacket, and control the temperature inside the kettle through an external circulation refrigeration pump; 1 kg of hexafluoropropylene oxide monomer was fed into the reaction kettle through a metering device, the feeding rate was controlled at 400 sccm, the reaction kettle was pumped to -1 bar, and the temperature inside the kettle was maintained at -15°C. After the completion of feeding, the reaction was stirred and kept stirring for 3h.

[0061] After the reaction, the crude product was taken out from the reaction kettle, and the product in the lower layer was removed after liquid separation, and filtered to obtain 0.995 kg of the crude product, and the conversion rate of hexafluoropropylene oxide was calculated to be 99.5%. Take a small amount of the obtained crude product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com