Method for preparing glyzinc under high pressure

A technology of zinc glycerol and conditions, which is applied in the preparation of metal alcohols, etc., can solve the problems of environmental protection and waste water, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

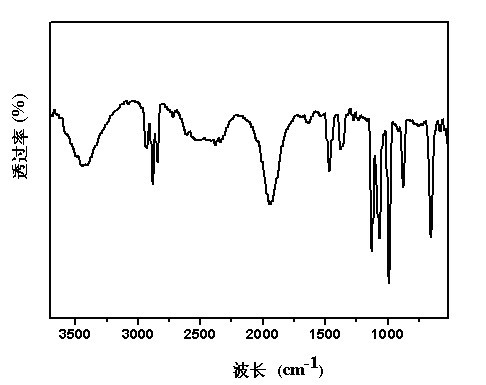

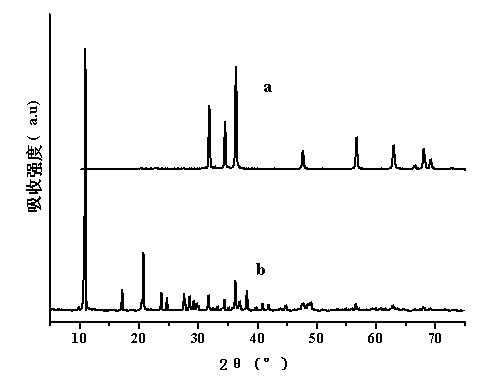

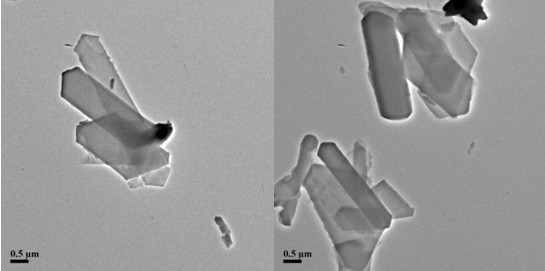

Image

Examples

Embodiment 1

[0019] Weigh 60g of glycerol and place it in a 250mL round bottom flask, heat it to 80°C under stirring conditions, add 3g of zinc oxide after reaching the temperature, mix and heat under reflux at this temperature for 5h, then move the mixture into a high-pressure reactor, The reaction was continued at ℃ for 60 h. After the reaction was completed, the reaction product was cooled to room temperature, washed with water and ethanol and repeated 3 times, and the solid was dried at 100 ℃ to constant weight after filtration to obtain the zinc glycerol product.

Embodiment 2

[0021] Weigh 60g of glycerin and place it in a 250mL round bottom flask, heat it to 120°C under stirring conditions, add 3g of zinc oxide after reaching the temperature, mix and heat under reflux at this temperature for 4h, then move the mixture into a high-pressure reactor, Continue to react at ℃ for 18 hours. After the reaction is completed, the reaction product is cooled to room temperature, washed with water and ethanol and repeated 3 times. After filtration, the solid is dried at 100 ℃ to constant weight to obtain the zinc glycerol product.

Embodiment 3

[0023] Weigh 60g of glycerol and place it in a 250mL round bottom flask, heat it to 120°C under stirring conditions, add 3g of zinc oxide after reaching the temperature, mix and heat at this temperature to reflux for 3h, then move the mixture into an autoclave, The reaction was continued at ℃ for 6 h. After the reaction was completed, the reaction product was cooled to room temperature, washed with water and ethanol and repeated 3 times, and the solid was dried at 100 ℃ to constant weight after filtration to obtain the zinc glycerol product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com