Continuous production process for sodium methoxide by using metal sodium method

A production process and technology for sodium metal, applied in the field of continuous production process of sodium methoxide by sodium metal method, can solve the problems of large floor space, many hidden safety hazards, high labor cost, etc., and achieve small floor space, convenient operation and stable product. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

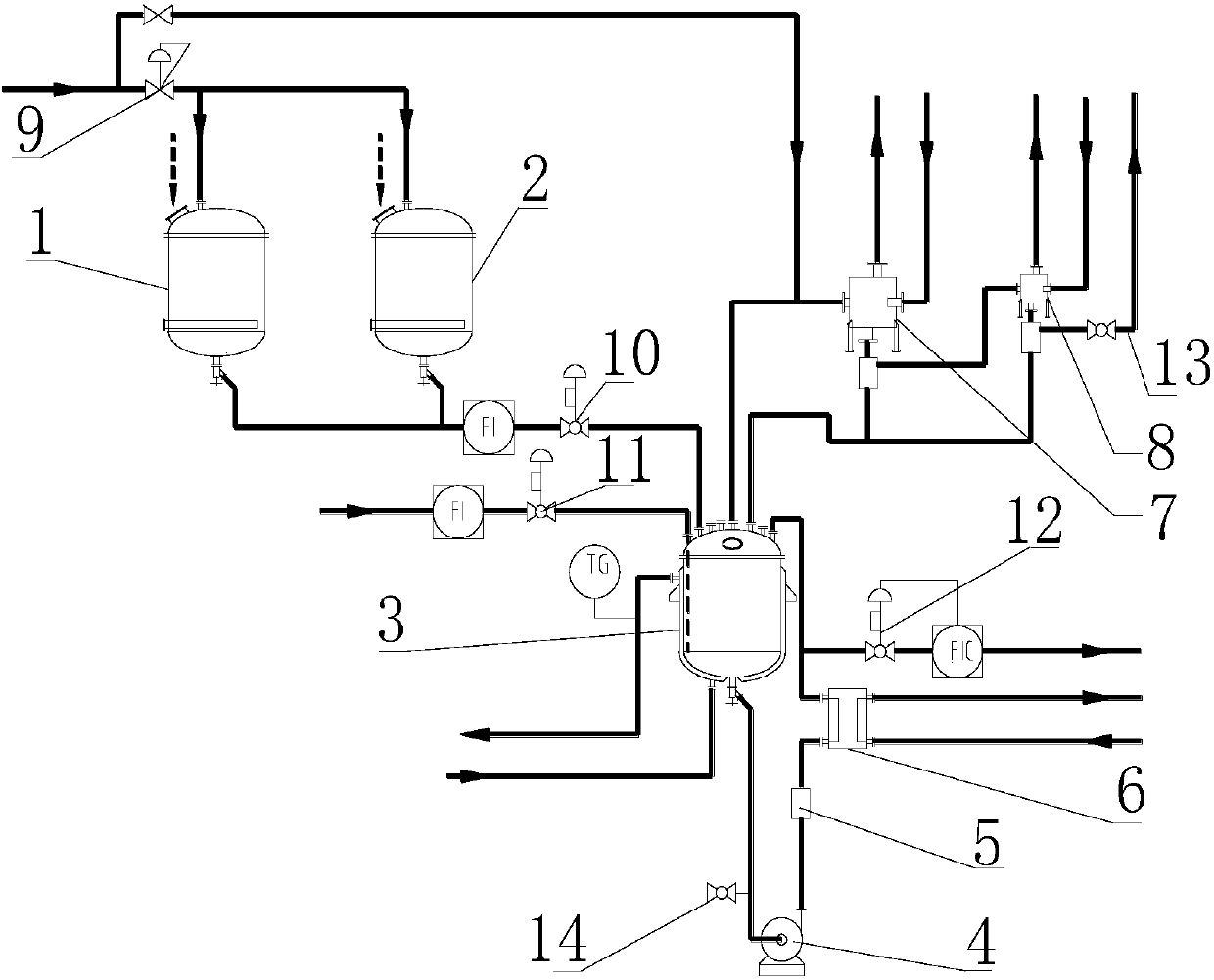

[0031] Such as figure 1 Shown, a kind of metal sodium method sodium methylate continuous production process is divided into three steps: preparation stage, metal sodium melting stage, continuous production operation stage;

[0032] Step 1) In the preparation stage, nitrogen replacement is carried out to the reaction unit system, and the metal sodium feed regulating valve 10, the methanol feed regulating valve 11, the sodium methylate discharge regulating valve 12 and the vent valve 13 are closed, and then to the reaction kettle 3, the circulating pump 4. Filter 5, circulating liquid cooler 6, primary condenser 7, secondary condenser 8 and their pipelines are filled with nitrogen gas. When the pressure on the reactor 3 reaches 0.1MPa, open the vent valve 3 to release the pressure, repeat 3 After the above procedures, open the vent val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com