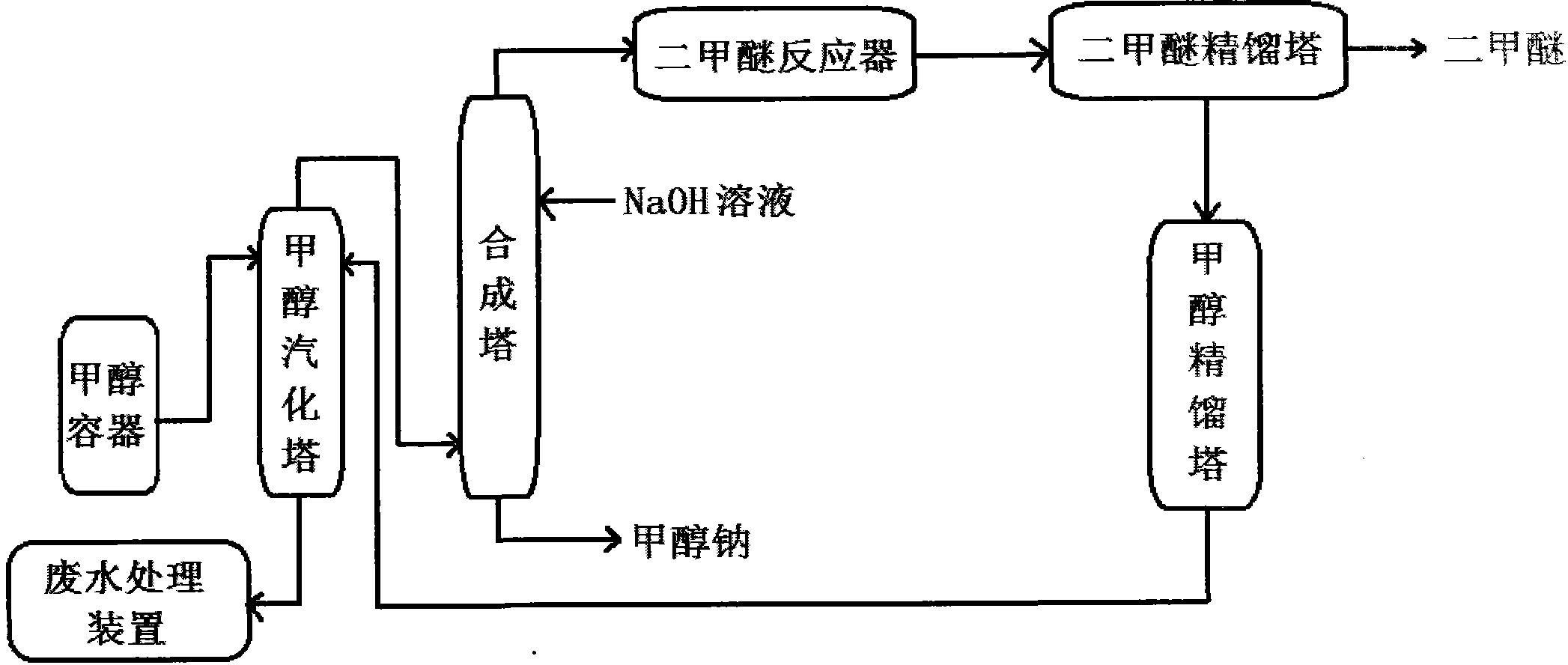

Sodium methoxide and dimethyl ether combined production technology

A technology for sodium methoxide and dimethyl ether, which is applied in the field of co-production technology for preparing sodium methoxide and dimethyl ether, can solve the problems of high energy consumption and large thermal energy consumption, and achieves the advantages of reducing energy consumption and equipment investment and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The raw material methanol is 85 (wt)% methanol, and in the synthesis tower, the reaction temperature of methanol and sodium hydroxide is 80°C, and the reaction pressure is 0.5MPa; in the dimethyl ether reactor, the reaction temperature is 215°C, and the reaction pressure is 0.5MPa, methanol liquid volume space velocity is 1.8 hours -1 , the reaction product enters the middle and lower part of the dimethyl ether rectification tower to realize the separation of dimethyl ether and methanol, and obtains a still liquid containing methanol, water, etc. grade dimethyl ether products. The dimethyl ether rectification tower is a plate tower with a total of 92 theoretical trays, of which the rectification section has 68 trays, the top pressure is 0.70MPa, the top temperature is 25°C, and the reflux ratio is 1.8. Among them, the dehydration catalyst used in the dimethyl ether reactor is based on ZSM-5 molecular sieve, and it is impregnated in NaBF containing 1.0wt% 4 and 2.0wt% ...

Embodiment 2

[0025] The raw material methanol is 85 (wt)% methanol, and in the synthesis tower, the reaction temperature of methanol and sodium hydroxide is 80°C, and the reaction pressure is 0.5MPa; in the dimethyl ether reactor, the reaction temperature is 215°C, and the reaction pressure is 0.5MPa, methanol liquid volume space velocity is 1.8 hours -1 , the reaction product enters the middle and lower part of the dimethyl ether rectification tower to realize the separation of dimethyl ether and methanol, and obtains a still liquid containing methanol, water, etc. grade dimethyl ether products. The dimethyl ether rectification tower is a plate tower with a total of 92 theoretical trays, of which the rectification section has 68 trays, the top pressure is 0.70MPa, the top temperature is 25°C, and the reflux ratio is 1.8. Among them, the dehydration catalyst used in the dimethyl ether reactor is based on ZSM-5 molecular sieve, and it is impregnated in NaBF containing 1.0wt% 4 and 2.0wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com