Method for preparing alkoxyl magnesium solid particles

A technology of magnesium alkoxide and magnesium oxide, which is applied in the field of preparation of magnesium alkoxide solid particles, can solve the problems of not being able to fully meet the requirements of high-performance olefin catalysts, being difficult to apply to industrialized production, and unable to obtain round particles, etc. , to achieve the effect of excellent particle shape, good particle shape maintenance, and easy control of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

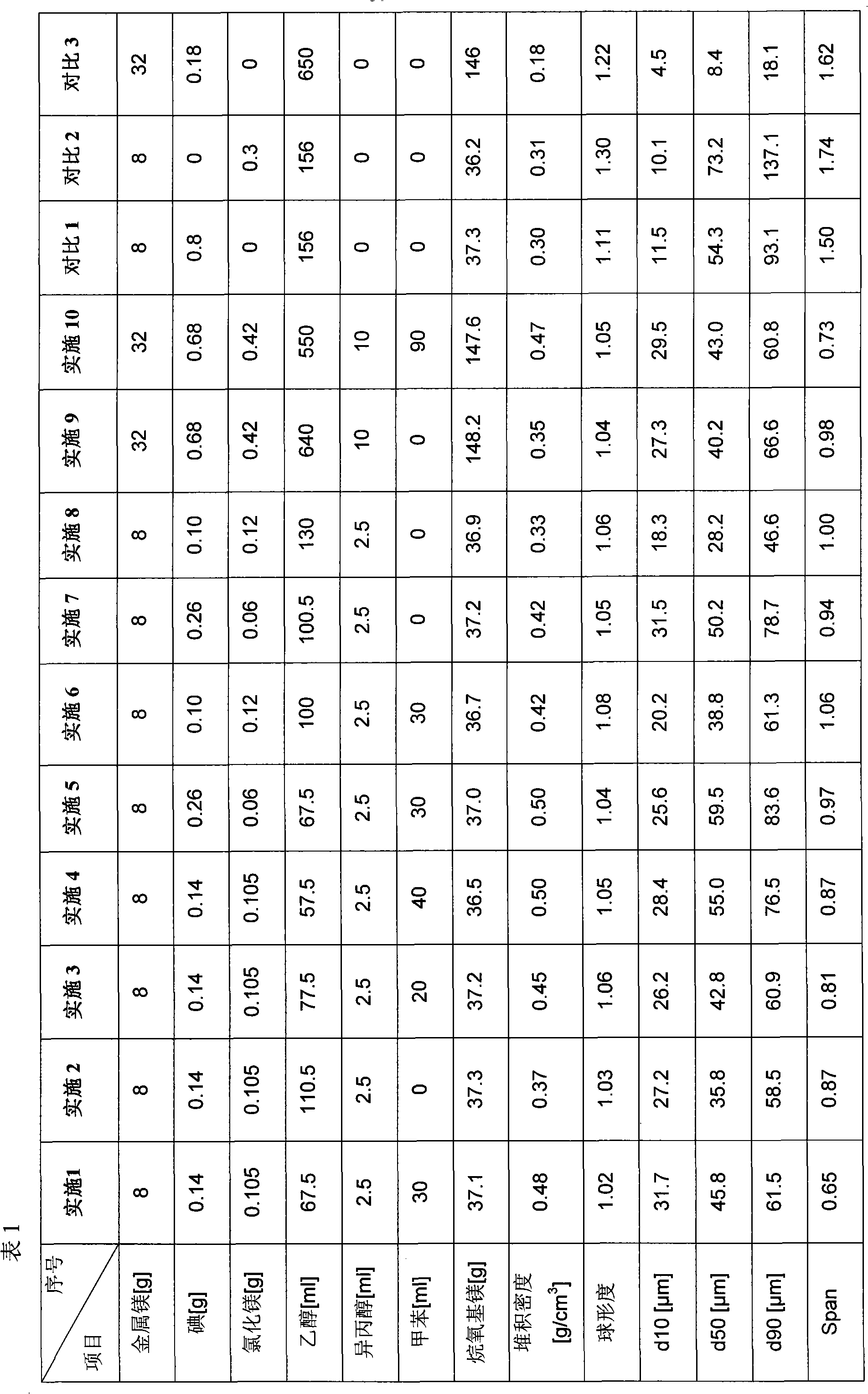

Examples

Embodiment 1

[0047] Example 11: Use the alkoxymagnesium particles prepared by the present invention to prepare solid catalyst components: In a 300ml reactor that has been repeatedly replaced with high-purity nitrogen, add 10ml of refined toluene and 90ml of titanium tetrachloride, and cool down to - 5°C, add the suspension prepared in advance with 10g of magnesium alkoxide obtained in Example 1 and 50ml of toluene, then slowly heat up to 80°C, add 2ml of DNBP (dibutyl phthalate), continue to heat up to 115°C, and keep the temperature constant 2 hours, and then filter the liquid clean. Then add a mixture of 120ml titanium tetrachloride and 30ml toluene and raise the temperature to 110°C and stir for 1 hour. Treat like this 3 times, filter off the liquid, wash the resulting solid with 150ml hexane at 60°C for 4 times, filter off the liquid and dry , Obtaining 10.5g of solid powder was the solid catalyst component, and the titanium content was determined to be 2.65 (wt)% by spectrophotometry....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com