Sulfate preparation method

A sulfuric acid ester and sulfuryl fluoride technology, which is applied in the field of sulfuric acid ester preparation, can solve the problems of high investment in environmental protection, high manufacturing cost, and affecting product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

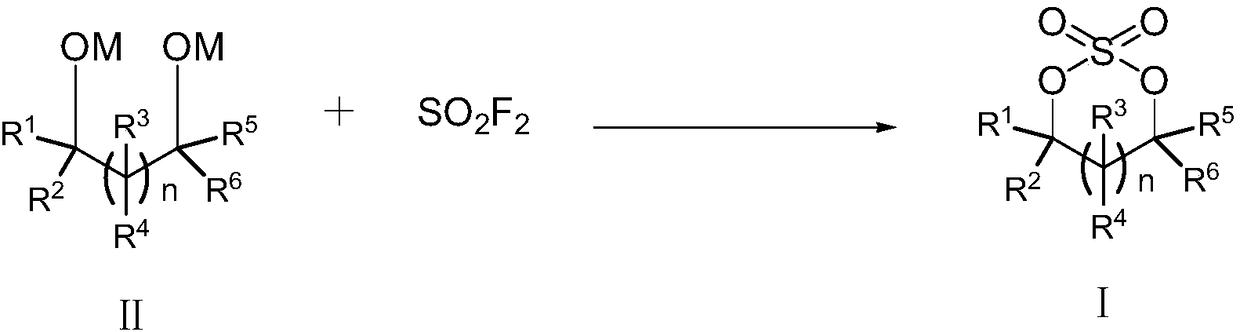

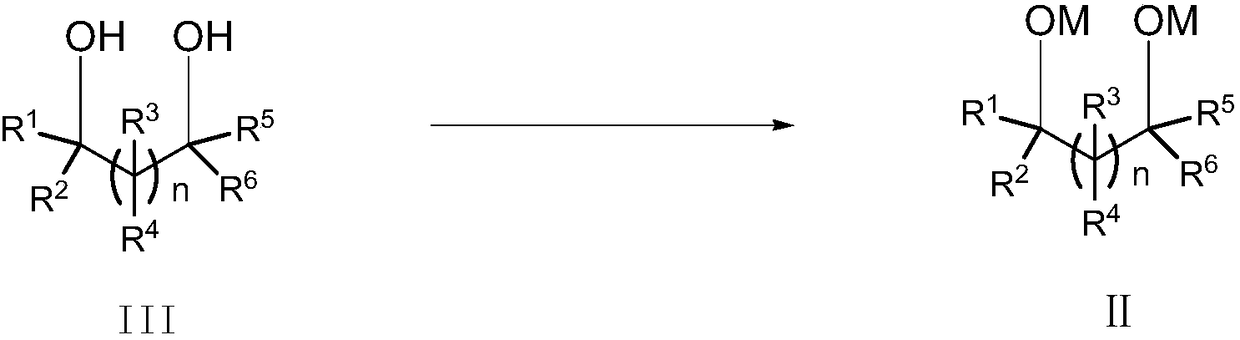

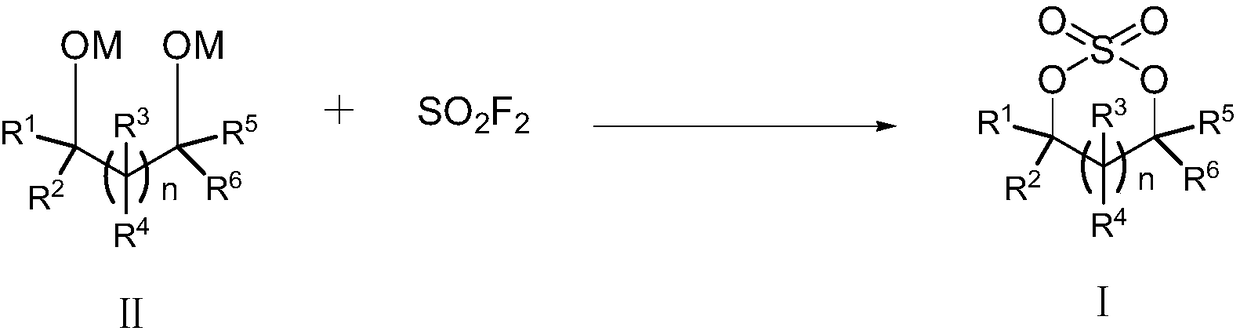

[0049] The present invention provides a kind of preparation method of sulfuric acid ester on the one hand, the chemical structural formula of described sulfuric acid ester is shown in formula I, and the preparation method of described sulfuric acid ester can comprise: formula II compound is mixed with sulfur under the condition that reaction solvent exists Acyl fluoride reaction, preparation obtains the compound of formula I, and reaction equation is as follows:

[0050]

[0051]Among them, n can be selected from 0, 1, 2, 3 or 4; M can be selected from Li, Na, K; R1, R2, R3, R4, R5, R6 can be independently selected from H, C1~C4 alkyl , C6-C18 aryl, C1-C4 alkoxy, chlorine or bromine. The C1-C4 alkyl group may be, for example, methyl, ethyl, propyl, n-propyl, isopropyl, butyl, n-butyl, isobutyl, sec-butyl, tert-butyl and the like. The C6-C18 aryl group may be, for example, phenyl, naphthyl, fluoranthenyl, fluorenyl, tetrahydronaphthyl, indanyl, anthracenyl and the like. Th...

Embodiment 1

[0071] Preparation of vinyl sulfate:

[0072] Put 200ml of toluene, 75g of ethylene glycol (1.2mol) and 80g (2mol) of sodium hydroxide into the reaction bottle equipped with a water separator, heat up to the reflux temperature and react, and observe that water continuously distills out in the water separator. After 20 hours, the reaction was completed, and the solvent in the system was evaporated to dryness to obtain ethylene glycol disodium salt, which weighed 107.3 g and was set aside.

[0073] In a 1000mL reaction flask, under the protection of nitrogen, add 106.0g of ethylene glycol disodium salt and 500mL of dichloromethane prepared in the above steps, keep the internal temperature at -10~10°C and slowly pass in 148.7g (1.47mol) of sulfuryl fluoride gas, keep warm React for 1.5 hours, blow nitrogen gas for 1 hour, filter, and desolvate the filtrate under reduced pressure at 40°C to obtain the crude solid. Cool down to room temperature, filter and dry to obtain 91.5 g of ...

Embodiment 2

[0075] Preparation of propylene sulfate:

[0076] Drop into 200ml toluene, 1,3-propanediol 100g (1.31mol) and 110g sodium methylate (2.04mol) in the reaction bottle that water separating device is housed, stir and be warming up to the low boiler in reflux separation system, slowly cool down after 15 hours, Add 200ml of dichloromethane to form a sodium salt suspension for later use.

[0077] In a 2000mL autoclave, replace the air with nitrogen. After adding 500ml of dichloromethane, 145.3g of sulfuryl fluoride was introduced into the autoclave under the protection of nitrogen to maintain an internal temperature of -10-0°C, and the sodium salt suspension was dropped into the autoclave, and kept for 2 hours for reaction. After the reaction, blow the system with nitrogen to remove excess sulfuryl fluoride gas, filter the reaction solution, and precipitate it to dryness under reduced pressure. Add 300ml of methyl tert-butyl ether, 15-crown-50.05g, 18-crown-6 0.05g to the crude pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com