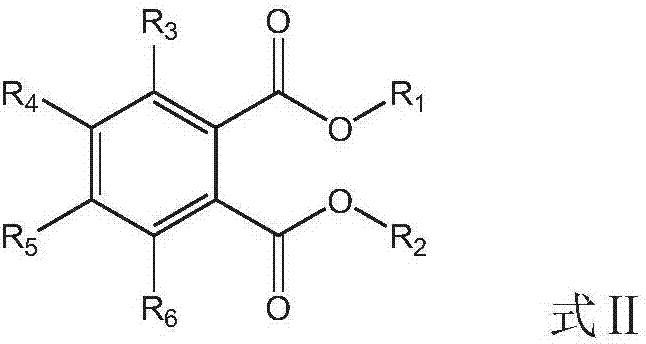

Alkoxy magnesium particles and application thereof

A magnesium alkoxide and particle technology, applied in organic chemistry, alcohol metal preparation, titanium organic compounds, etc., can solve the problems of complex operation, low capacity density, viscosity increase, etc., to achieve uniform particle distribution, high catalyst activity, high The effect of stereoregularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

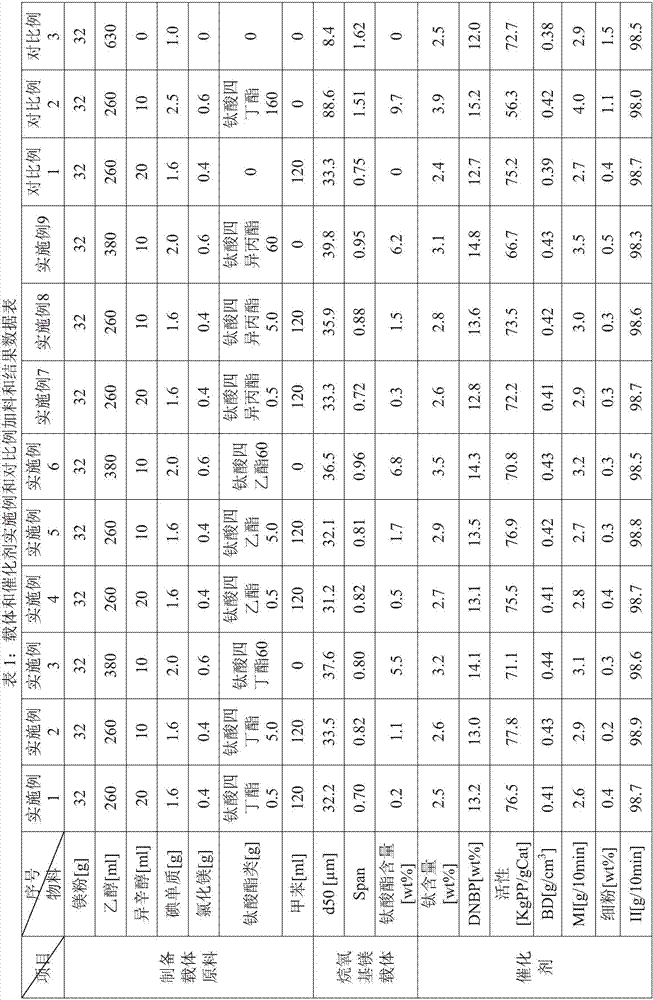

Embodiment 1-9

[0062] Preparation of alkoxymagnesium particles: In a reactor with a stirrer, a reflux condenser, a thermometer and a burette are installed. After fully replacing with nitrogen, add ethanol with a water content of less than 200ppm and a small amount of isooctyl alcohol with a water content of less than 200ppm into the reactor, and add iodine element and magnesium chloride to dissolve it. Then magnesium powder (less than 300 μm) and toluene were added. A certain amount of titanate compound is added into the reaction feed solution for reaction. After stirring, the temperature is raised until the reflux temperature of the reaction system is reached, and the reaction is carried out until completion, that is, no hydrogen gas is discharged. It is then washed, separated and dried. See Table 1 for details on the amount of each raw material added and the results.

[0063] The prepared alkoxymagnesium particles are used to prepare solid catalyst components: in a 300mL reactor that ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com