Efficient composite heat stabilizer for pentaerythritol cerium-based PVC and preparation method of heat stabilizer

A technology of compounding heat stabilizer and pentaerythritol, applied in the chemical industry, can solve the problems of restricting the popularization and application of non-toxic and environmentally friendly heat stabilizers, high cost, unsatisfactory heat stabilization effect of heat stabilizers, etc. Precipitation, good stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

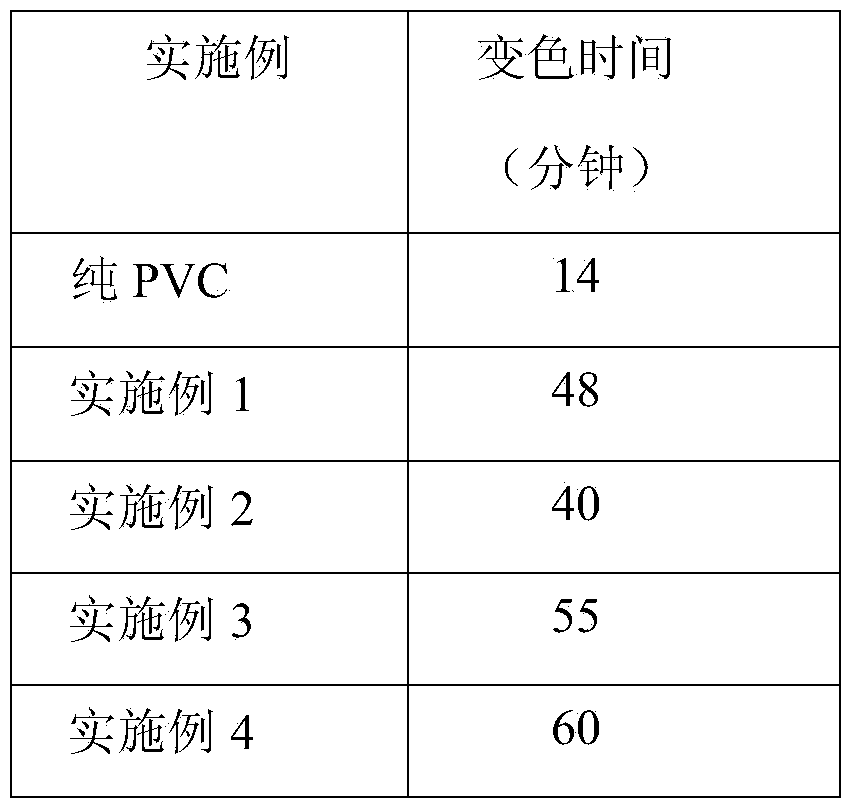

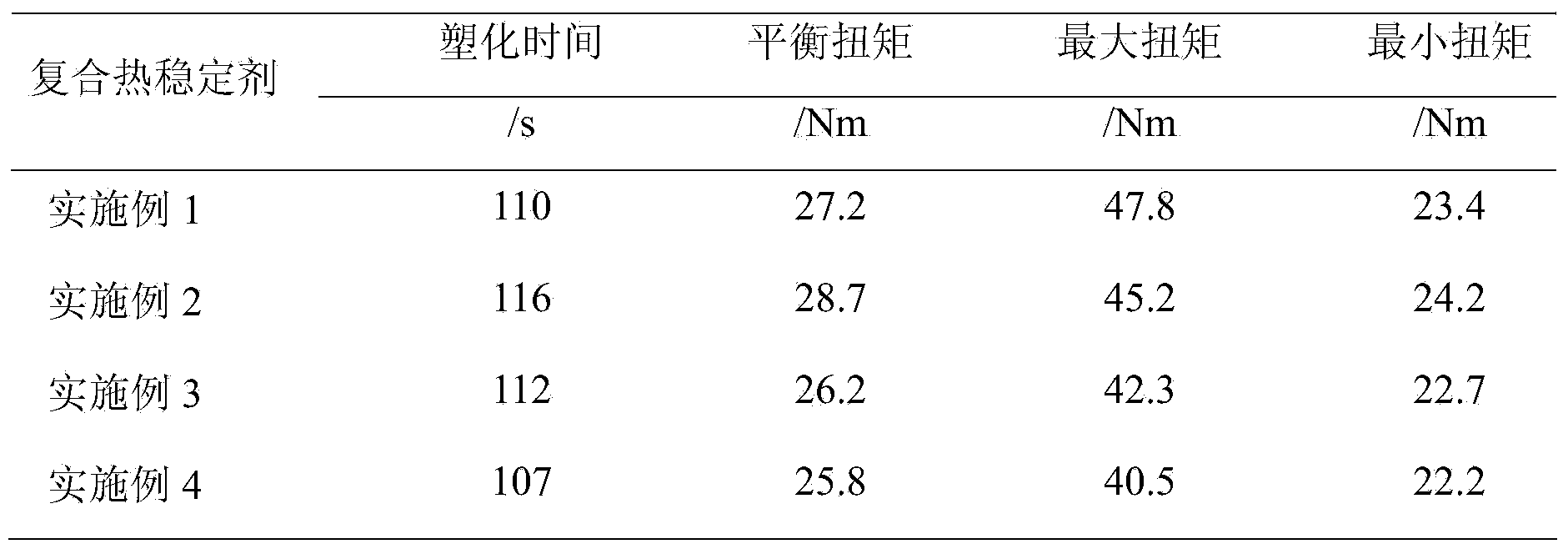

Embodiment 1

[0021] Preparation of pentaerythritol cerium: Weigh 25kg of pentaerythritol and 28kg of cerium carbonate, pulverize and mix them fully with a pulverizer, add to the reaction kettle, then add 0.1kg of acetic acid and stir evenly, heat the oil bath to 190°C, stir while heating, and react 5 Hours later, the material was taken out to cool down, and after crushing, cerium pentaerythritol was obtained.

[0022] Preparation of high-efficiency composite heat stabilizer for pentaerythritol cerium-based PVC: First, add 42kg of pentaerythritol cerium, 12kg of barium stearate and 20kg of calcium stearate into the reaction kettle and mix them thoroughly, then take the mixed materials, add them to a kneader and knead at 100°C After 25 minutes, 25kg of paraffin wax, 4kg of stearyl benzoylmethane, 3kg of triphenyl phosphite and 3kg of bisphenol A were successively added to the kneader, kneaded and stirred for 30 minutes, discharged, sieved and packaged to obtain the final product.

Embodiment 2

[0024] Preparation of pentaerythritol cerium: Weigh 20kg of pentaerythritol and 21kg of cerium carbonate, pulverize and mix them fully with a pulverizer, add to the reaction kettle, then add 0.2kg of acetic acid and stir evenly, heat the oil bath to 190°C, stir while heating, and react 4 Hours later, the material was taken out to cool down, and after crushing, cerium pentaerythritol was obtained.

[0025] Preparation of environment-friendly and high-efficiency composite heat stabilizer for pentaerythritol cerium-based PVC: First, add 30kg of pentaerythritol cerium, 10kg of barium stearate and 30kg of calcium stearate into the reaction kettle and mix them thoroughly. Knead for 30 minutes, then sequentially add 30kg of paraffin wax, 4kg of stearyl benzoylmethane, 3kg of triphenyl phosphite and 3kg of bisphenol A into the kneader, knead and stir for 35 minutes, discharge, sieve and pack to obtain the final product.

Embodiment 3

[0027] Preparation of cerium pentaerythritol: Weigh 35kg pentaerythritol and 38kg cerium carbonate, pulverize and mix them fully with a pulverizer, add to the reaction kettle, then add 0.4kg acetic acid and stir evenly, heat the oil bath to 170°C, stir while heating, reaction 4.5 Hours later, the material was taken out to cool down, and after crushing, cerium pentaerythritol was obtained.

[0028] Preparation of environment-friendly and high-efficiency composite heat stabilizer for pentaerythritol cerium-based PVC: First, add 40kg of pentaerythritol cerium, 15kg of barium stearate and 25kg of calcium stearate into the reaction kettle and mix them thoroughly. Knead for 20 minutes, then sequentially add 20kg of paraffin wax, 6kg of stearyl benzoylmethane, 3kg of triphenyl phosphite and 3kg of bisphenol A into the kneader, knead and stir for 40 minutes, discharge, sieve and pack to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com