Method and device for preparing ethylene glycol antimony through microwave reaction

A technology of ethylene glycol antimony and microwave reaction, which is applied to the preparation of metal alcohols, chemical instruments and methods, chemical/physical/physicochemical processes using energy, etc., can solve the problems of long time and high energy consumption, and achieve short reaction time , low energy consumption, increase the effect of full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

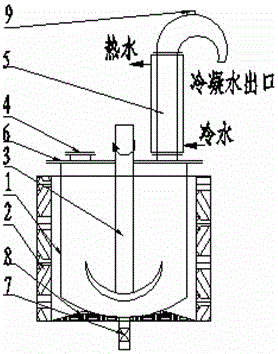

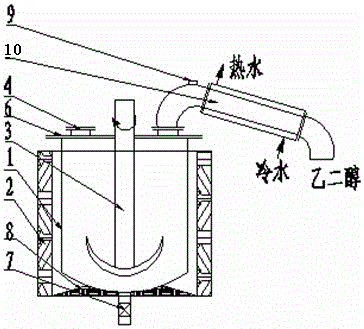

Method used

Image

Examples

Embodiment 1

[0052] The microwave reaction of the present embodiment prepares the method for ethylene glycol antimony, comprises the following steps:

[0053] In a 0.5L microwave reactor equipped with a microwave heating device, a condensing reflux device, and a stirrer, add 300 mL of ethylene glycol and 150 g of antimony trioxide at a liquid-solid ratio of ethylene glycol to antimony trioxide of 2:1, Start the microwave heating device, the microwave frequency is 2450MHz, the stirring speed is controlled at 30 rpm, the reaction temperature is controlled at 140-145°C, and the temperature of the outlet gas of the condensation reflux device is controlled at 90-100°C; when the mixture in the reactor reaches the controlled temperature, During heat preservation reaction 15 minutes, at this moment, reaction material is clear and transparent, adds activated carbon 1.2g, then heat preservation and stirring 10 minutes, filter and obtain clear filtrate; Filtrate enters crystallization tank, carries ou...

Embodiment 2

[0064] In a 10L microwave reactor equipped with a microwave heating device, a condensing reflux device, and a stirrer, according to the liquid-solid ratio of ethylene glycol and antimony trioxide 3:1, add 7500 mL of ethylene glycol and 2500 g of antimony trioxide respectively, and start Microwave heating device, the microwave frequency is 2450MHz, the stirring speed is controlled at 50 rpm, the reaction temperature is controlled at 155-160°C, and the temperature of the outlet gas of the condensation reflux device is controlled at 100-110°C; when the mixture in the reactor reaches the controlled temperature, keep warm When reacting for 25 minutes, at this time, the reaction material was clear and transparent, and 12.5 g of activated carbon was added, and then it was incubated and stirred for 10 minutes, and filtered to obtain a clear filtrate; Vacuum drying to obtain ethylene glycol antimony product 3531.0g, its quality index is: whiteness 93.6%, Sb56.78%, As0.0015%, Pb0.0006%, ...

Embodiment 3

[0067] In a 10L microwave reactor equipped with a microwave heating device, a condensing reflux device, and a stirrer, according to the liquid-solid ratio of ethylene glycol and antimony trioxide at 4:1, add 7200 mL of ethylene glycol and 1800 g of antimony trioxide respectively, and start Microwave heating device with a microwave frequency of 2450MHz; control the stirring speed to 70 rpm, control the reaction temperature to 170-175°C, and control the outlet gas temperature of the condensation reflux device to 110-120°C; when the mixture in the reactor reaches the controlled temperature, keep warm When reacting for 40 minutes, at this moment, the reaction material was clear and transparent, and 12.6 g of activated carbon was added, and then it was incubated and stirred for 10 minutes, and filtered to obtain a clear filtrate; Vacuum drying to obtain 2514.8g of ethylene glycol antimony product, its quality index is: whiteness 93.7%, Sb57.12%, As0.0013%, Pb0.0007%, Cu0.0004%, Fe0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com