Process for synthesizing zinc pentaerythritol in heat stabilizer

A technology for the synthesis of zinc pentylenetethritol, which is applied in the field of synthesis of zinc pentaerythritol, can solve the problems of no thermal stability effect, hinder the smooth progress of processing, affect the transparency of products, etc., and achieve long-term thermal stability Strong resistance, ability to inhibit, and the effect of inhibiting zinc burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: take by weighing active zinc oxide and pentaerythritol powder 121.5g and 136.0g respectively and add in the high-speed mixer and mix, wherein the rotating speed of the high-speed mixer is 1500r / min, after mixing for 5 minutes, place a three-necked flask, and the reaction temperature setting: 140°C, vacuum degree: -100KPa, react for 60min, and stir at 1000r / min. After the reaction, cool the product to room temperature and pulverize it with an ultrafine pulverizer to obtain zinc pentaerythritol C.

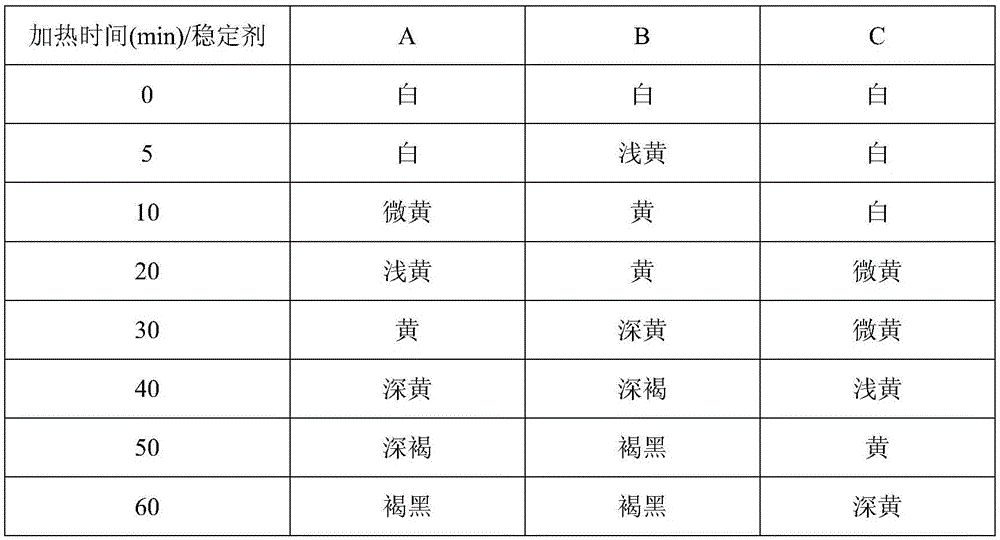

[0017] Comparison of zinc stearate A, pentaerythritol B and pentaerythritol zinc C in oven aging experiments

[0018] Among them A: zinc stearate: hydrotalcite 1:1

[0019] B: pentaerythritol: hydrotalcite 1:1

[0020] C: zinc pentaerythritol: hydrotalcite 1:1

[0021] figure 1 For the analysis diagram of the experimental results, refer to figure 1 As shown, the prepared zinc pentaerythritol has the anti-incipient coloring property of zinc stearate, and has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com