PVC co-extrusion exterior wall cladding and preparation method thereof

A technology of PVC resin and hanging board, applied in the field of plastic processing, which can solve the problems of insufficient thermal stability, easy decomposition, poor thermal stability of PVC molecules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

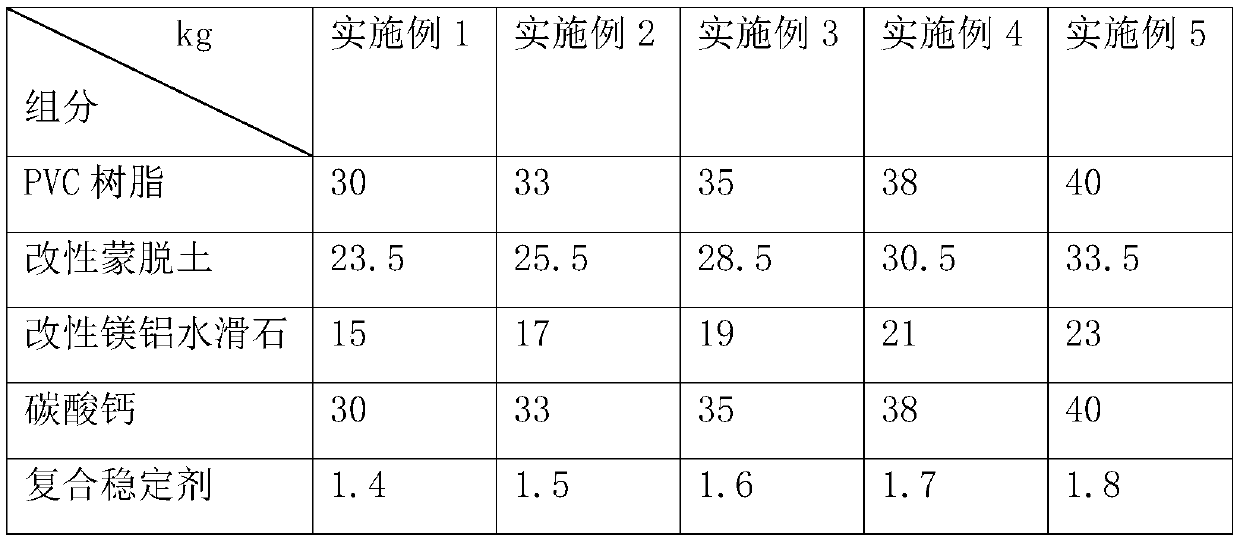

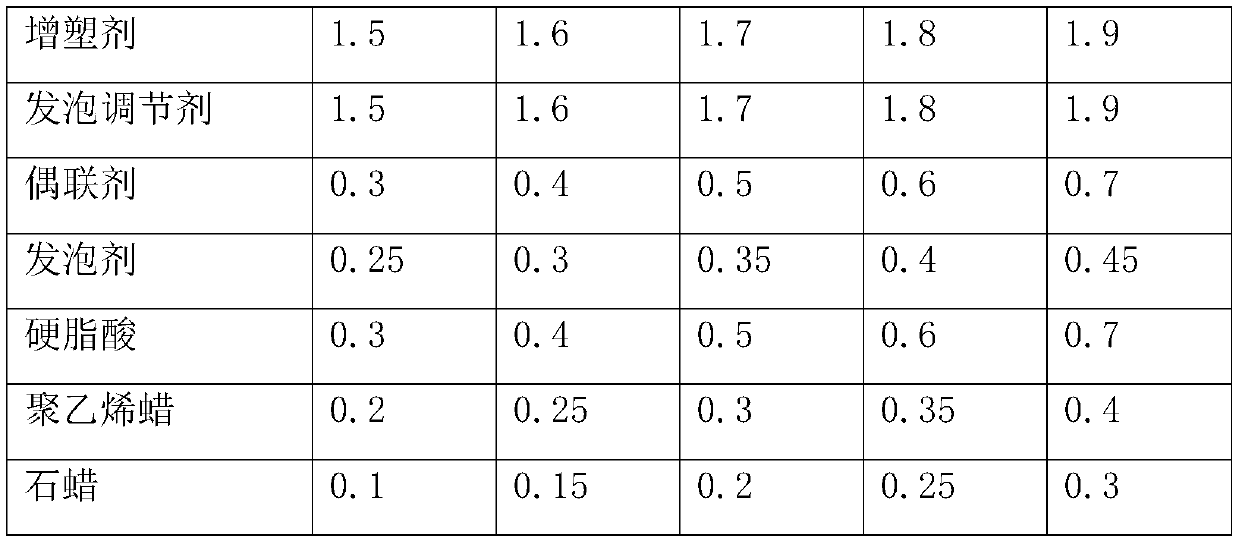

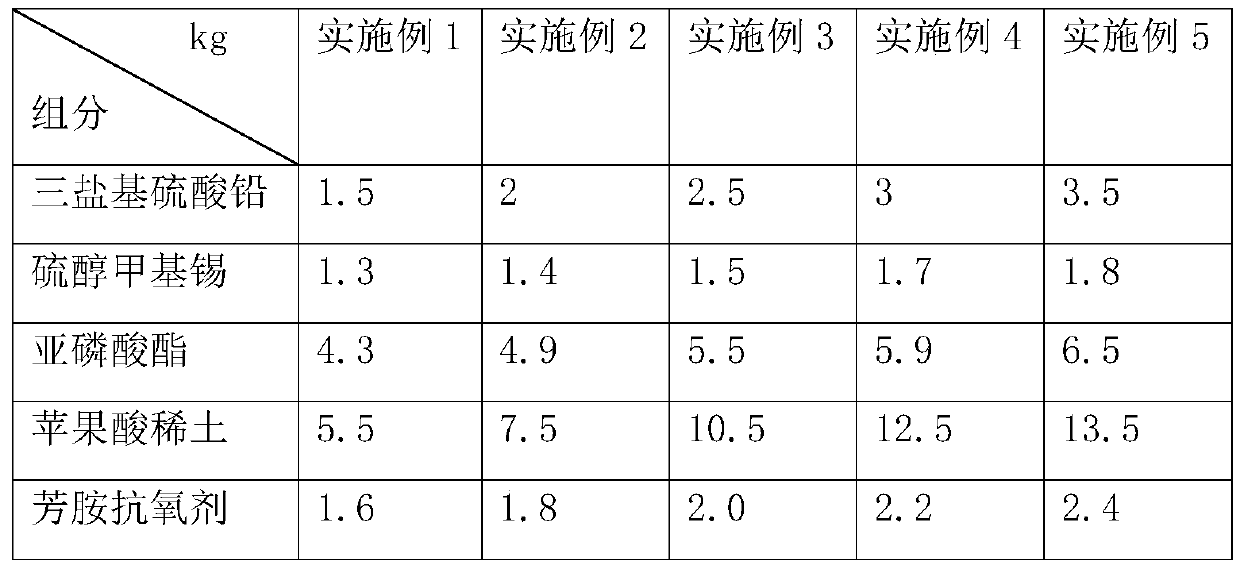

Examples

preparation example 1-3

[0043] In Preparation Examples 1-3, the polyurethane was selected from the polyurethane with the product number 141B sold by Shandong Gonghengderui Polyurethane Co., Ltd., and the tung oil was selected from the 009 tung oil sold by Jinan Xinsenyuan Chemical Co., Ltd.

preparation example 1

[0044] Preparation Example 1: (1) Place sodium-based montmorillonite in a sulfuric acid solution with a concentration of 0.6g / L, stir at 80°C for 3 hours at high speed, filter while hot, and wash twice with sulfuric acid with a mass concentration of 2%, Then wash with distilled water to neutrality, suction filter, dry, grind, and pass through a 300-mesh sieve to obtain pretreated montmorillonite powder, the mass ratio of sodium-based montmorillonite and sulfuric acid solution is 1:3;

[0045] (2) Put 2.5kg of pretreated montmorillonite powder in 5kg of ethanol solution with a mass concentration of 50%, ultrasonically disperse at 50°C for 3h, add 0.25kg of KH-570 silane coupling agent, keep warm and stir for 2h, add 1.2kg methyl methacrylate, 0.5kg trimethylphenylphosphorus iodide, 0.3kg tung oil and 1.2kg polyurethane, keep stirring for 3 hours, add 0.1kg of azobisisobutyronitrile after 0.3h of nitrogen gas, and keep warm for reaction After 5 hours, filter with suction, dry, g...

preparation example 2

[0046] Preparation example 2: (1) Put the sodium montmorillonite in a sulfuric acid solution with a concentration of 0.7g / L, stir at a high speed for 2.5h at 85°C, filter while it is hot, and wash twice with sulfuric acid with a mass concentration of 2%. , and then washed with distilled water to neutrality, suction filtration, drying, grinding, and passing through a 300-mesh sieve to obtain pretreated montmorillonite powder, the mass ratio of sodium-based montmorillonite and sulfuric acid solution is 1:4;

[0047](2) Place 3kg of pretreated montmorillonite powder in 6kg of 50% ethanol solution, ultrasonically disperse at 55°C for 2.5h, add 0.3kg of KH-570 silane coupling agent, insulate and stir for 2.5h, Add 1.4kg of methyl methacrylate, 0.6kg of trimethylphenyl phosphorus iodide, 0.4kg of tung oil and 1.4kg of polyurethane, keep stirring for 3.5h, and feed nitrogen for 0.4h, then add 0.2kg of azobisisobutyronitrile, Insulated for 5 hours, suction filtered, dried, ground, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com