Preparation method of vanadyl ethylene glycol and method for preparing M-phase vanadium dioxide powder from vanadyl ethylene glycol

A technology of vanadyl glycolate and vanadium dioxide, which is applied in the preparation of vanadyl glycolate and vanadium dioxide powder, and in the field of preparation of M-phase vanadium dioxide powder, which can solve the problem of difficult preparation of M-phase Vanadium, high synthesis cost and other problems, to achieve the effect of easy large-scale industrial production, low cost and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

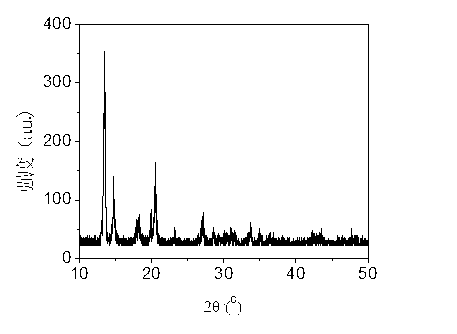

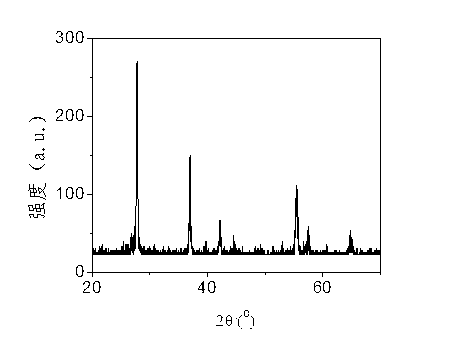

[0034] Example 1: 1 gram of ammonium metavanadate was added to 20 grams of ethylene glycol for ultrasonic dispersion treatment for 2 minutes, stirred in an oil bath at 160°C for 60 minutes, cooled to room temperature, and vacuum filtered to obtain a blue-purple precipitate of ethylene glycol vanadyl, The precipitate was washed with acetone until the filtrate was colorless, and the precipitate was put into a blast-type heating oven at 180° C., kept for 60 minutes, and taken out to obtain a blue-black M-phase vanadium dioxide powder.

Embodiment 2

[0035] Example 2: Add 1 gram of amorphous vanadium dioxide to 1 gram of ethylene glycol and 20 grams of benzyl alcohol for ultrasonic dispersion treatment for 3 minutes, stir in an oil bath at 200°C for 25 minutes; cool to room temperature, and vacuum filter to obtain ethylene glycol oxygen Vanadium blue-purple precipitates, the precipitate is washed with acetone until the filtrate is colorless, put the precipitate in a vacuum oven at 280°C, keep it warm for 5 minutes, and take it out to obtain blue-black M-phase vanadium dioxide powder.

Embodiment 3

[0036] Example 3: Add 1 gram of vanadyl acetylacetonate to 1000 grams of ethylene glycol and 50 grams of propylene glycol and glycerol for ultrasonic dispersion for 3 minutes, stir in an oil bath at 200°C for 5 minutes; cool to room temperature, and vacuum filter to obtain ethylene glycol The vanadyl alkoxide is precipitated, and the precipitate is washed with acetone until the filtrate is colorless. The precipitate is placed in a vacuum drying oven at 200° C., kept for 40 minutes and taken out to obtain a blue-black M-phase vanadium dioxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

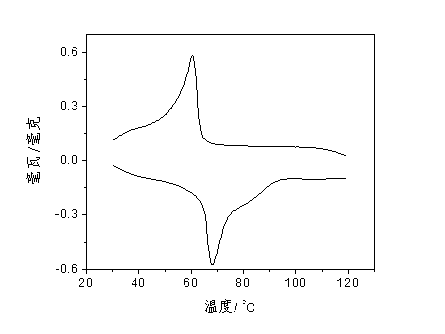

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com