Method for simultaneously preparing pure iron alloy and carbide derived carbon by using carbon iron alloy as raw material

A carbide-derived carbon and ferroalloy technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of high price of carbide-derived carbon, complex preparation process, long production cycle, etc., to reduce production costs, simple equipment operation, environmental protection low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

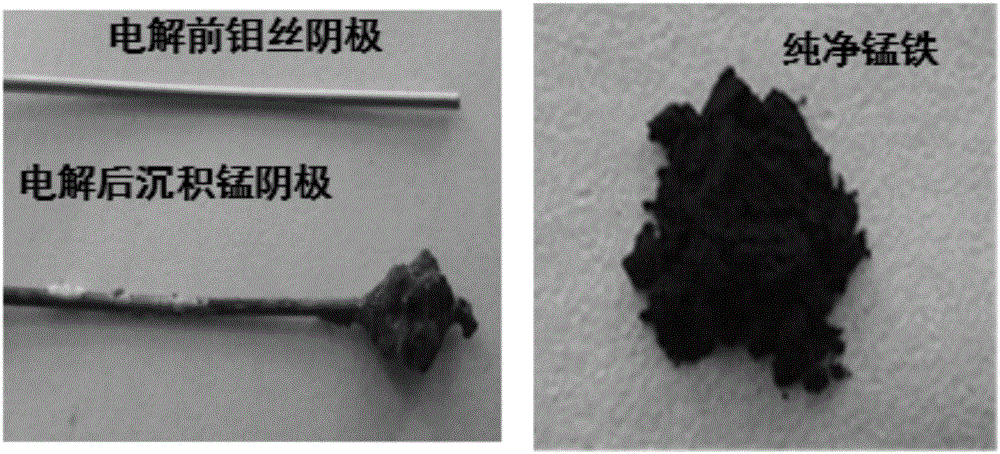

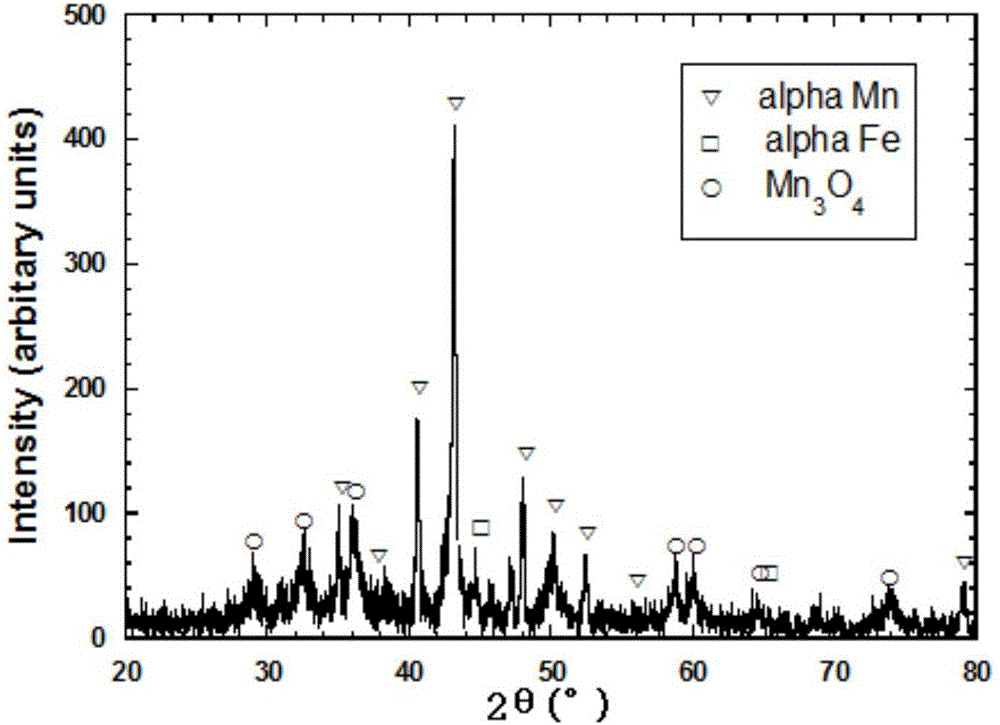

[0023] Heat the high-carbon ferromanganese to 1300°C in an electric furnace to melt, take it out at high temperature and cast it into a copper mold, and quickly cool it to make a rod (5mm in diameter, 50mm in length), then connect the high-carbon ferromanganese with a conductive material and draw it out as an anode. High-purity tungsten (purity>99.9%, diameter 8mm, length 80mm) was used as cathode. In the resistance furnace, use the alumina corundum crucible as the electrolytic cell, weigh 35g of sodium chloride and 43g of potassium chloride, with a total weight of 78g, put them into the alumina corundum crucible, pass argon gas into the resistance furnace, and turn on cooling water , Then, raise the temperature to 200°C, keep the temperature for 2h to remove moisture, and then raise the temperature to 710°C to melt the mixed salt. Finally, put the electrode into a corundum crucible, and conduct electrolysis at a voltage of 0.3V through a DC stabilized power supply for 4 hours...

Embodiment 2

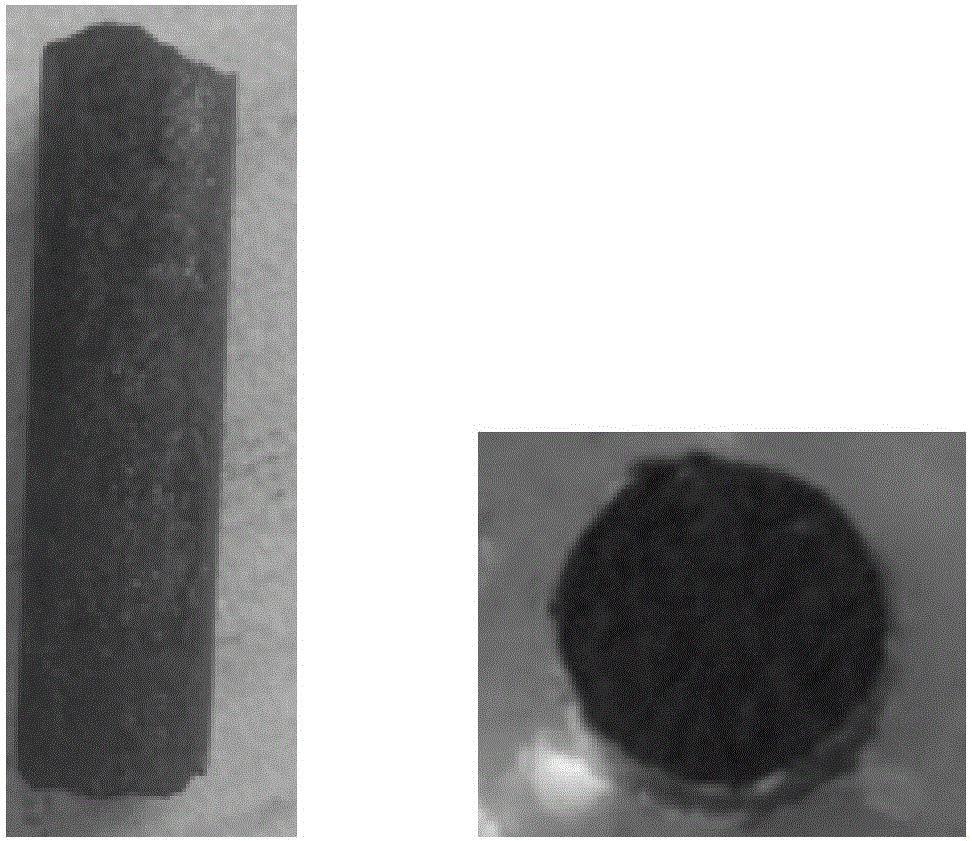

[0028] Heat high-carbon ferrochrome to 1900°C in a vacuum induction furnace to melt, take it out and cast it into mullite insulation bricks with good thermal insulation performance to cool slowly, and make it into a plate with a fixed size (thickness 3mm, length and width) Both are 40mm), and then the high-carbon ferrochrome is connected with the conductive material and drawn out as the anode, and the high-purity molybdenum (purity>99.9%, diameter 8mm, length 80mm) is used as the cathode. In the resistance furnace, use the alumina corundum crucible as the electrolytic cell, weigh 30g of sodium chloride and 40g of potassium chloride, with a total weight of 70g, put them into the alumina corundum crucible, pass argon gas into the resistance furnace, and turn on cooling water , Then, raise the temperature to 200°C, keep the temperature for 2h to remove moisture, and then raise the temperature to 720°C to melt the mixed salt. Finally, put the electrode into a corundum crucible, an...

Embodiment 3

[0030] Heat high-carbon ferrovanadium to 1800°C in a vacuum induction furnace to melt, take it out at high temperature and cast it into a copper mold, and quickly cool it to prepare a rod shape (diameter 5mm, length 50mm), then connect high-carbon ferrovanadium with conductive material and lead it out as anode. High-purity tungsten (purity>99.9%, diameter 8mm, length 80mm) was used as cathode. In the resistance furnace, use the alumina corundum crucible as the electrolytic cell, weigh 36g of sodium chloride and 39g of potassium chloride, with a total weight of 75g, put them into the alumina corundum crucible, pass argon gas into the resistance furnace, and turn on cooling water , Then, raise the temperature to 200°C, keep the temperature for 2h to remove moisture, and then raise the temperature to 740°C to melt the mixed salt. Finally, put the electrode into a corundum crucible, and conduct electrolysis at a voltage of 0.4V through a DC stabilized power supply for 8 hours. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com