Carbide derived carbon adsorbent for removing low-concentration low-molecular-weight VOCs (volatile organic compounds) as well as preparation method of adsorbent

A technology of carbide-derived carbon and volatile organic compounds, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as poor adsorption capacity, and achieve long service life, excellent adsorption performance, and large adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

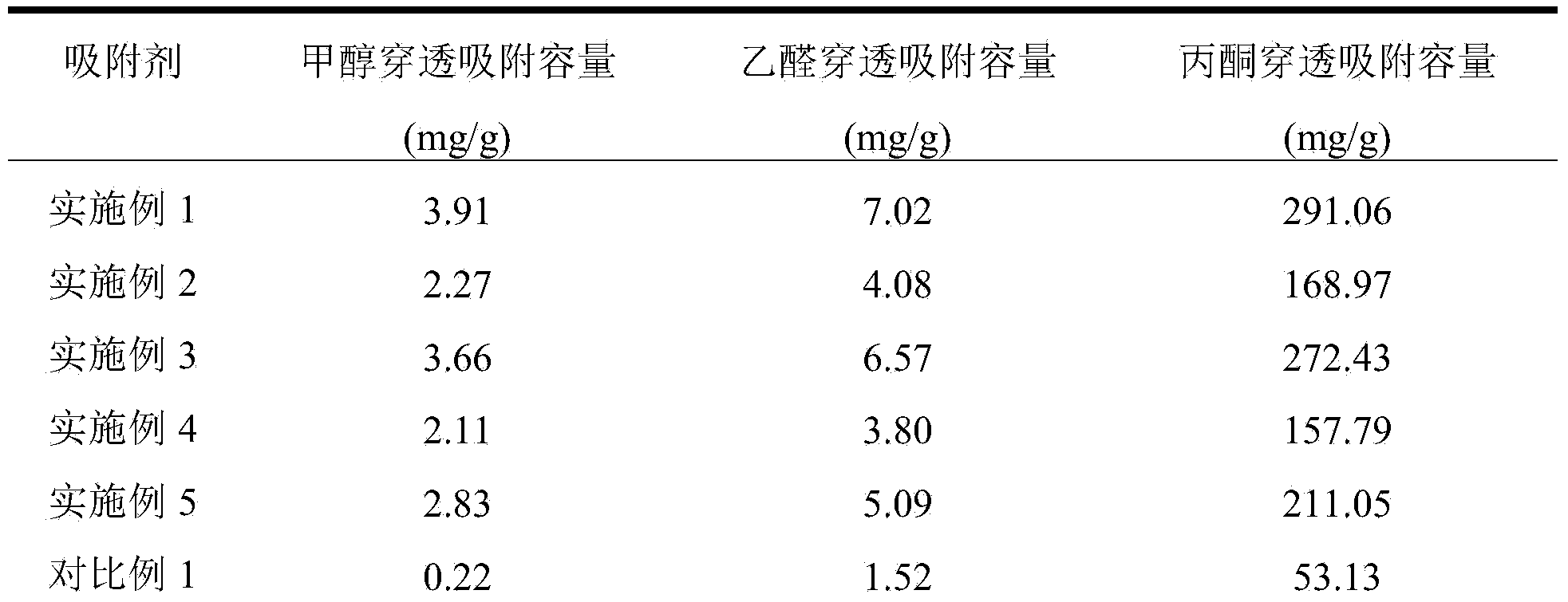

Embodiment 1

[0015] Heat 4g of TiC to 700°C in an inert atmosphere, and then change to chlorine gas (30ml / min) for 2 hours for high-temperature etching. Then, cool to room temperature with inert gas again to obtain the primary product. Add 1 g of the resulting primary product to 10 ml of an oxidative solution HNO with a molar concentration of 5 mol / L 3 Immersion treatment at medium room temperature for 12 hours. Then, wash with deionized water until neutral, and dry at 105° C. for 8 hours to obtain the adsorbent of Example 1.

Embodiment 2

[0017] Heat 4gVC to 600°C in an inert atmosphere, and then change to chlorine gas (40ml / min) for 4 hours for high-temperature etching. Then, cool to room temperature with inert gas again to obtain the primary product. Add 1g of the resulting primary product to 10ml of 5% oxidizing solution H 2 o 2 Dipping treatment at medium room temperature for 6 hours. Then, wash with deionized water until neutral, and dry at 105° C. for 5 hours to obtain the adsorbent of Example 2.

Embodiment 3

[0019] 4gTiC was heated up to 800°C in an inert atmosphere, and then chlorine gas (30ml / min) was used for 2 hours for high-temperature etching. Then, cool to room temperature with inert gas again to obtain the primary product. Add 1 g of the resulting primary product to 10 ml of an oxidative solution HNO with a molar concentration of 9 mol / L 3 Immersion treatment at medium room temperature for 12 hours. Then, wash with deionized water until neutral, and dry at 105° C. for 8 hours to obtain the adsorbent of Example 3.

PUM

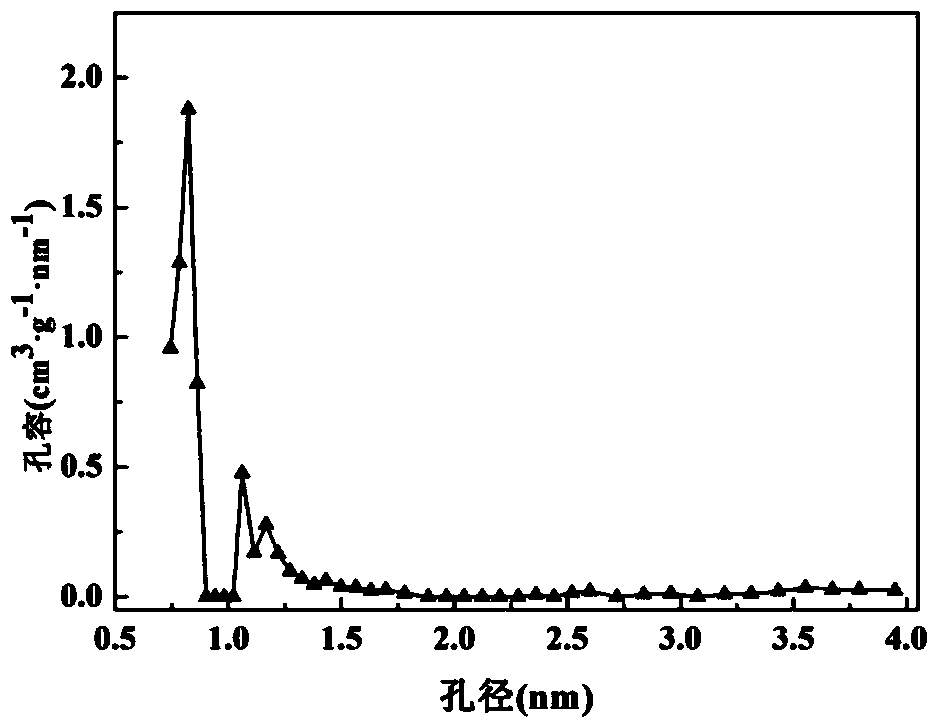

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com