Method for preparing carbide derived carbon by fused salt electrolysis method

A technology of carbide-derived carbon and molten salt electrolysis, which is applied in the direction of carbon preparation/purification, electrolysis process, electrolytic components, etc., and can solve the problems of restricting the wide application of carbide-derived carbon, high price of carbide-derived carbon, and serious environmental pollution, etc. problems, to achieve the effects of superior electrochemical performance, stable electrolysis process, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

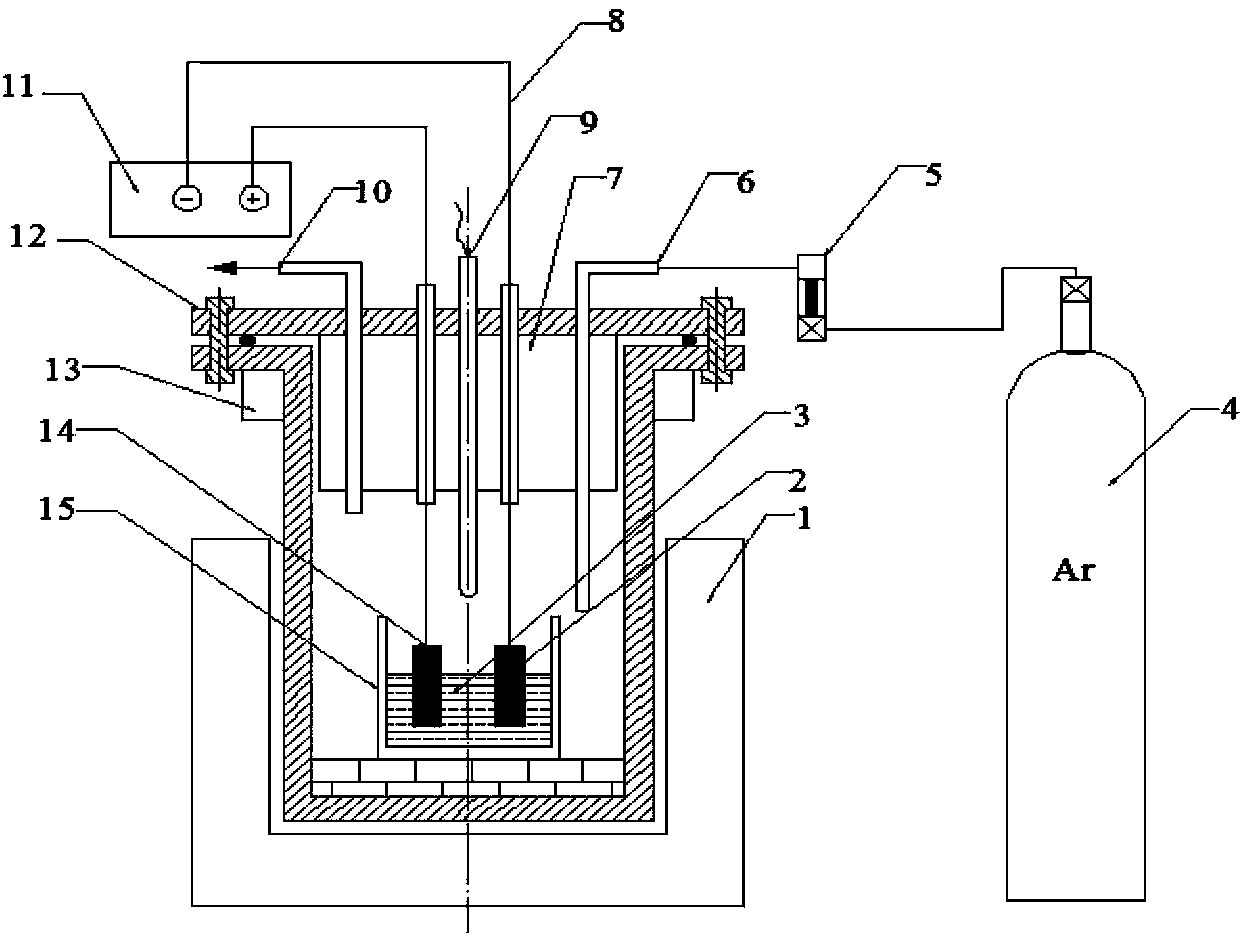

Method used

Image

Examples

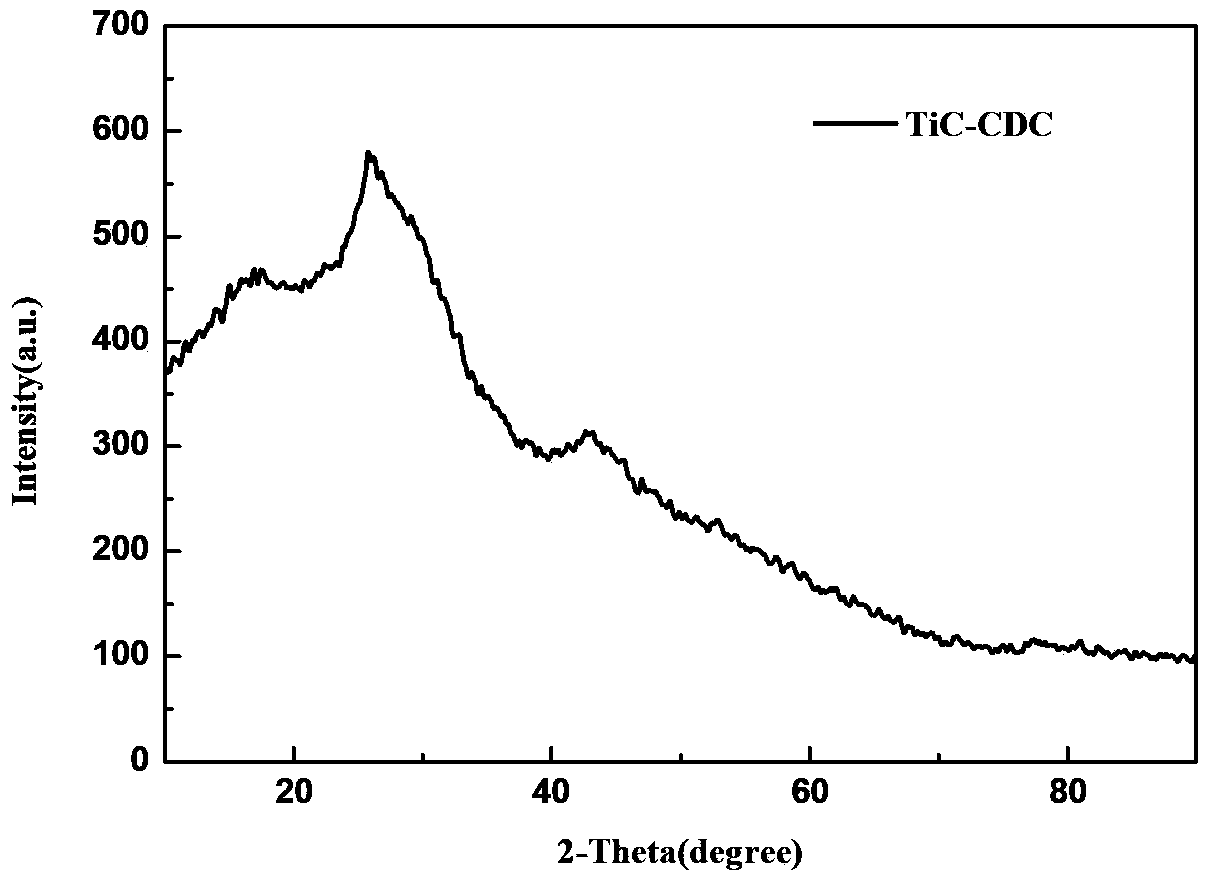

Embodiment 1

[0031] Weigh 1.5g of titanium carbide powder (2μm, 98%), mold it into a sheet under 3MPa pressure, then put it into a sintering furnace, fill it with argon, heat it up to 800°C for 8h, put the sintered titanium carbide sheet into Use electronically conductive materials to connect and lead out as positive electrodes, and use high-purity high-density graphite rods (carbon content >99.99%, density 1.5g / cm 3 ) as the negative electrode, in the electrolytic furnace with a ceramic crucible as the electrolytic cell, weigh 48 grams of potassium chloride, 120 grams of magnesium chloride, and 72 grams of sodium chloride (potassium chloride: magnesium chloride: sodium chloride = 0.2: 0.5: 0.3) total Put 240 grams into a ceramic crucible, put argon gas into the crucible resistance furnace, heat up to 400°C to melt it, put the positive and negative electrodes into the ceramic crucible, connect the positive and negative electrodes to 3.2V with DC stabilized voltage power supply, and perform ...

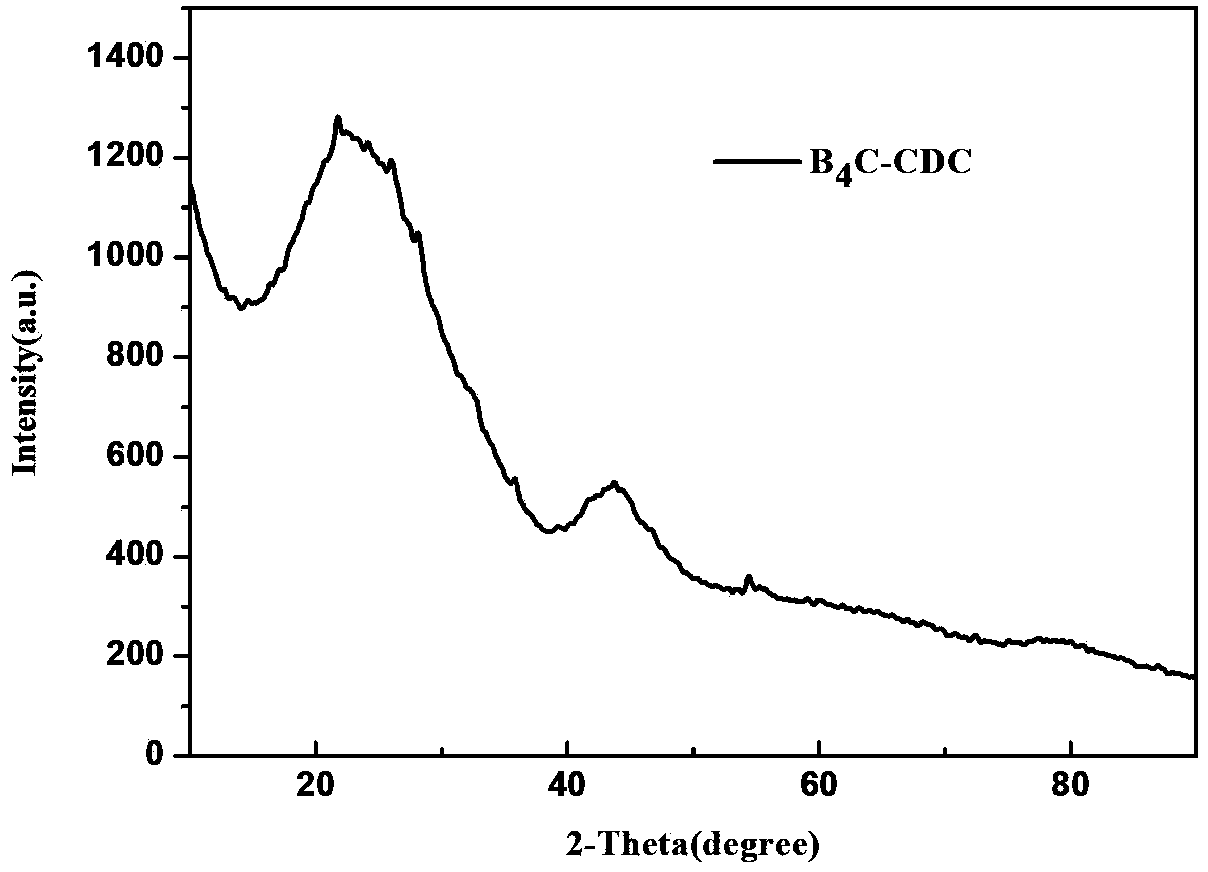

Embodiment 2

[0033] Weigh 1.5 grams of boron carbide powder (2μm, 98%), mold it into a tablet under a pressure of 5 MPa, then put it into a sintering furnace, fill it with argon, heat it up to 850 ° C for 7 hours, and put the sintered boron carbide sheet into In the positive pole basket as the positive pole, high-purity high-density graphite rods (carbon content>99.99%, density 1.5g / cm 3 ) as the negative electrode, use the ceramic crucible as the electrolytic cell in the electrolytic furnace, weigh 240 grams of magnesium chloride and put it into the ceramic crucible, pass argon gas into the crucible resistance furnace, heat up to 750 ° C and stabilize, put the positive and negative electrodes into the In the ceramic crucible, the DC stabilized power supply is connected to the positive and negative poles and energized at 3.0V for 45 hours of electrolysis. After the reaction, the product obtained from the positive electrode was sequentially washed with deionized water, ultrasonically assist...

Embodiment 3

[0035] Weigh 1.5 grams of silicon carbide powder (2μm, 98%), mold it into a tablet under a pressure of 8MPa, then put it into a sintering furnace, fill it with argon, heat it up to 900 ° C for 5 hours, and put the sintered silicon carbide chip into In the positive pole basket as the positive pole, high-purity high-density graphite rods (carbon content>99.99%, density 1.5g / cm 3 ) as the negative electrode, use the ceramic crucible as the electrolytic cell in the electrolytic furnace, weigh 240 grams of calcium chloride and put it into the ceramic crucible, pass argon gas into the crucible resistance furnace, raise the temperature to 900°C and stabilize, then put the positive and negative electrodes Put it into the crucible, connect the positive and negative poles of the DC stabilized power supply to 2.6V, and perform electrolysis for 30 hours. After the reaction, the product obtained from the positive electrode was sequentially washed with deionized water, ultrasonically assist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com