Method for regulating pore structure of carbide derived carbon

A carbide-derived carbon and pore structure technology, which is applied in the preparation/purification of carbon, can solve the problems of material specific surface reduction and reduction, and achieve the effects of sharp reduction of specific surface, simple process, and simple reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

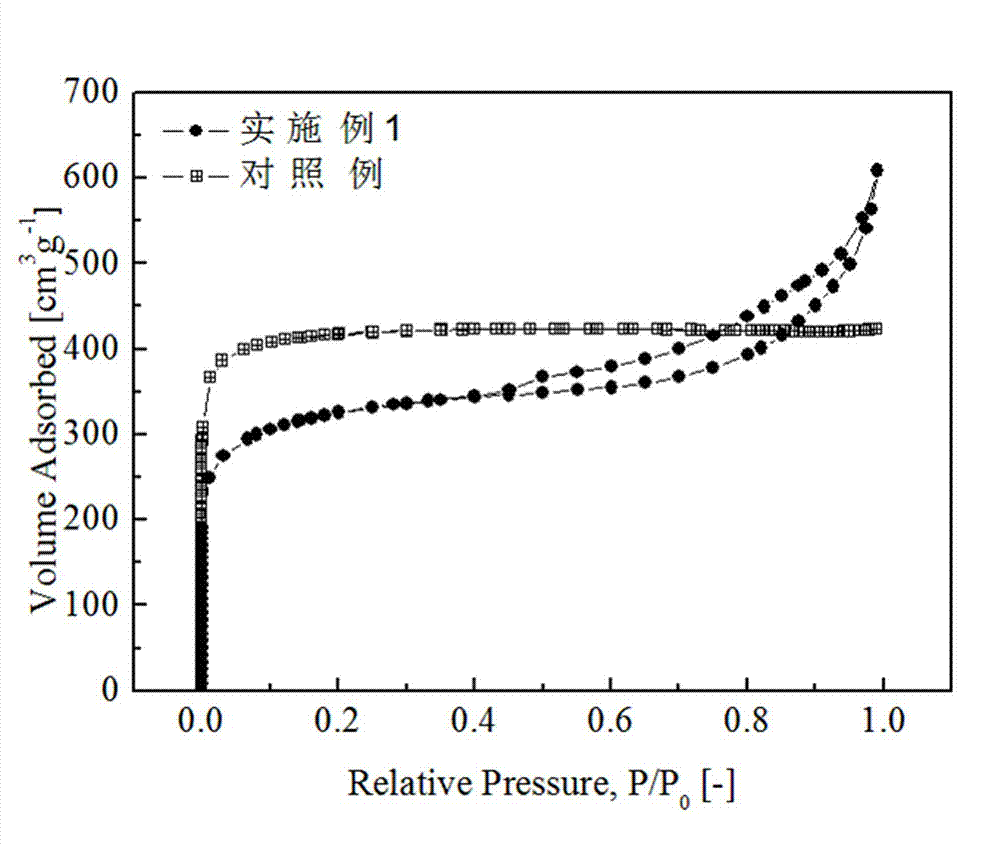

[0013] Take 20g of titanium carbide powder with a particle size of 800 mesh and put it into a high-energy ball mill, put in 120g of GCr15 bearing steel balls, and then put in 1ml of ethanol as a dispersant. The speed of the ball mill is 280 rpm, and the ball milling time is 8 hours. At this time, the particle size of the titanium carbide powder was about 1.2 μm. Then put the above-mentioned titanium carbide powder into a fused silica tube furnace, vacuumize to 0.1Pa and then pass in argon gas, raise the temperature of the tube furnace to 600°C, and pass in chlorine gas at a flow rate of 20ml / min for 3.0 Hour. After the reaction is completed, argon gas is introduced to remove residual chloride on the surface of the titanium carbide powder, and after the temperature is cooled to room temperature, a high specific surface carbide-derived carbon with a mesopore structure is obtained.

[0014] Such as figure 1 As shown, under the same process and parameters of the high-temperature...

Embodiment 2

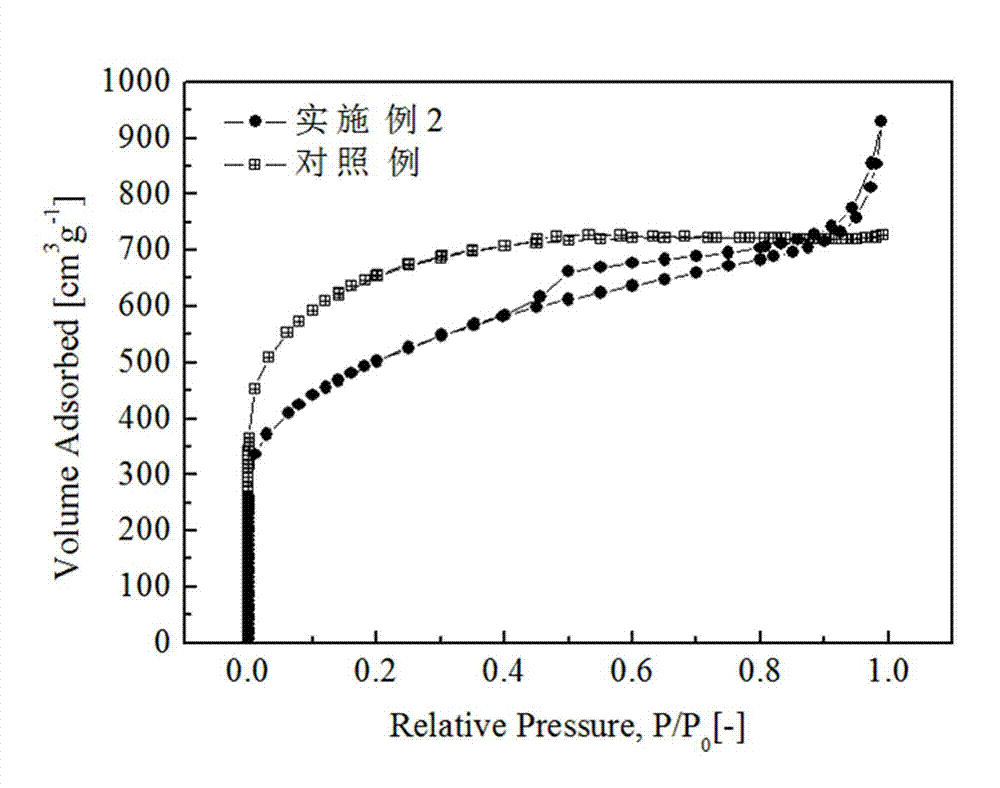

[0016] Take 20g of titanium carbide powder with a particle size of 800 mesh and put it into a high-energy ball mill, put in 160g of GCr15 bearing steel balls, and then put in 1ml of ethanol as a dispersant. The speed of the ball mill is 240 rpm, and the ball milling time is 12 hours. At this time, the particle size of the titanium carbide powder was about 0.6 μm. Then put the above-mentioned titanium carbide powder into a fused silica tube furnace, vacuumize to 0.05Pa, and then pass in argon gas. The temperature of the tube furnace was raised to 800° C., and chlorine gas was introduced at a flow rate of 30 ml / min for 1.0 hour. After the reaction is completed, argon is introduced to remove residual chloride on the surface of the titanium carbide powder. After the temperature drops to room temperature, a high specific surface carbide-derived carbon with a mesopore structure can be obtained.

[0017] Such as figure 2 As shown, under the same process and parameters of the high...

Embodiment 3

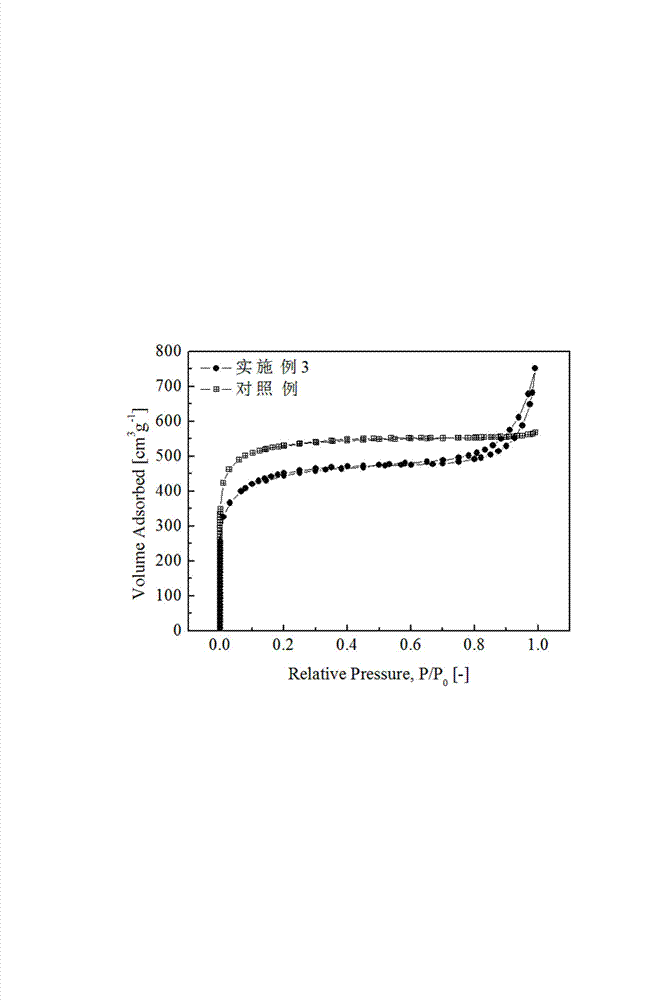

[0019] Take 20g of titanium carbide powder with a particle size of 800 mesh and put it into a high-energy ball mill, put in 140g of GCr15 bearing steel balls, and then put in 1ml of ethanol as a dispersant. The speed of the ball mill is 260 rpm, and the ball milling time is 10 hours. At this time, the particle size of the titanium carbide powder was about 0.9 μm. Then put the above-mentioned titanium carbide powder into a fused silica tube furnace, evacuate to 1 Pa, and then pass in argon gas. The temperature of the tube furnace was raised to 1000° C., and chlorine gas was introduced at a flow rate of 25 ml / min for 2.0 hours. After the reaction is completed, argon is introduced to remove residual chloride on the surface of the titanium carbide powder. After the temperature drops to room temperature, a high specific surface carbide-derived carbon with a mesopore structure can be obtained.

[0020] Such as image 3 As shown, under the same process and parameters of the high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com