Method for high-efficiency hydrogen reduction preparation of transition metal oxide defects

A transition metal and oxide technology, applied in the field of efficient hydrogen reduction to prepare transition metal oxide defects, can solve the problems of uneconomical practicability, high energy consumption and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

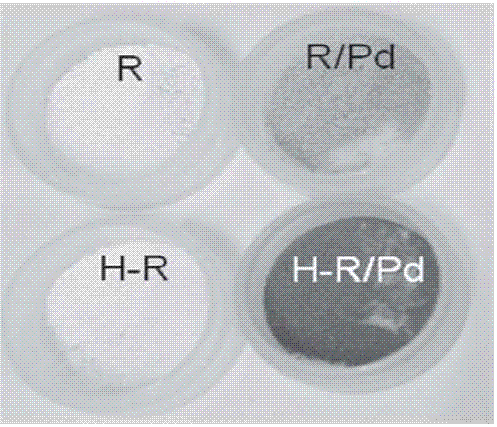

[0056] Weigh 0.5g rutile TiO 2 (R), dispersed into 500ml of ethylene glycol solution by ultrasonic or stirring. Then add 25mgNa 2 PdCl 4 , stirred for 6h. 5g of polyvinylpyrrolidone was added to the above mixed solution and stirred for 2h. The above mixed solution was heated to 180°C, stirred and refluxed for 2h. The above solution was centrifuged, the supernatant was poured off to collect the precipitate, and washed with ethanol and deionized water for 3 to 6 times, and after vacuum drying, the powder was calcined at 500° C. for 2 hours. Obtaining rutile TiO loaded with Pd noble metal 2 (R / Pd). Put R / Pd at normal pressure H 2 / Ar(10vol%H 2 ) under the airflow (80cm 3 / min) room temperature treatment for 20min, you can get rutile TiO with a lot of defects 2 (H-R / Pd).

Embodiment 2

[0058] Weigh 0.5g CeO 2 , and dispersed into 500ml of ethylene glycol solution by ultrasonic or stirring. Then add 25mg Na 2 PdCl 4 , stirred for 6h. 5g of polyvinylpyrrolidone was added to the above mixed solution and stirred for 2h. The above mixed solution was heated to 180°C, stirred and refluxed for 2h. The above solution was centrifuged, the supernatant was poured off to collect the precipitate, and washed with ethanol and deionized water for 3 to 6 times, and after vacuum drying, the powder was calcined at 500° C. for 2 hours. Obtaining CeO loaded with Pd noble metal 2 (CeO 2 / Pd). CeO 2 / Pd at atmospheric pressure H 2 / Ar(10vol%H 2 ) under the airflow (80cm 3 / min) at room temperature for 20 minutes, you can get CeO containing a large amount of low-valent reduced state 2 (H-Ce / Pd).

Embodiment 3

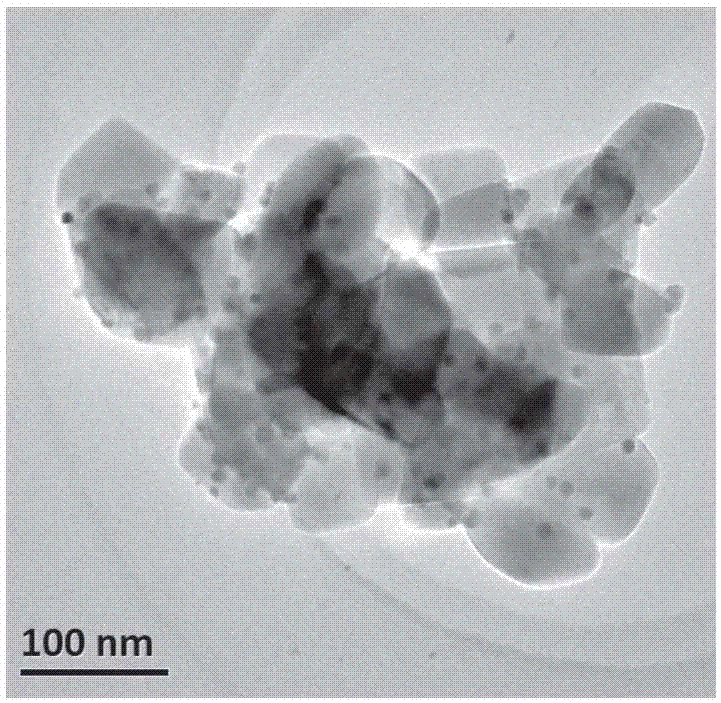

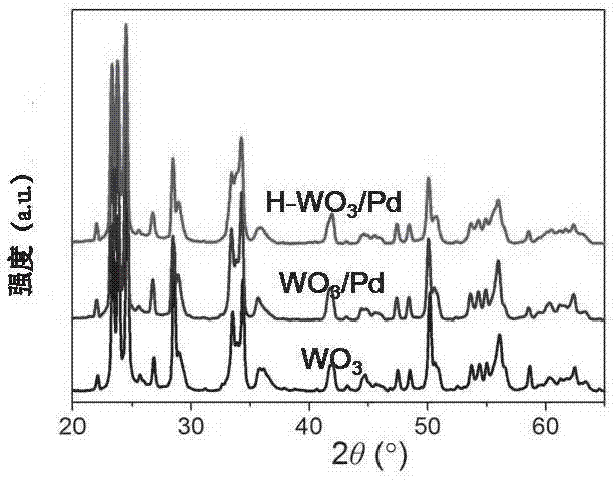

[0060] Weigh 0.5g WO 3 , and dispersed into 500ml of ethylene glycol solution by ultrasonic or stirring. Then add 25mg Na 2 PdCl 4 , stirred for 6h. 5g of polyvinylpyrrolidone was added to the above mixed solution and stirred for 2h. The above mixed solution was heated to 180°C, stirred and refluxed for 2h. The above solution was centrifuged, the supernatant was poured off to collect the precipitate, and washed with ethanol and deionized water for 3 to 6 times, and after vacuum drying, the powder was calcined at 500° C. for 2 hours. Obtain WO loaded with Pd noble metal 3 (WO 3 / Pd). WO 3 / Pd at atmospheric pressure H 2 / Ar(10vol%H 2 ) under the airflow (80cm 3 / min) Treated at room temperature for 20 minutes, you can get WO containing a large amount of low-valent reduced state 3 (H-WO 3 / Pd).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com