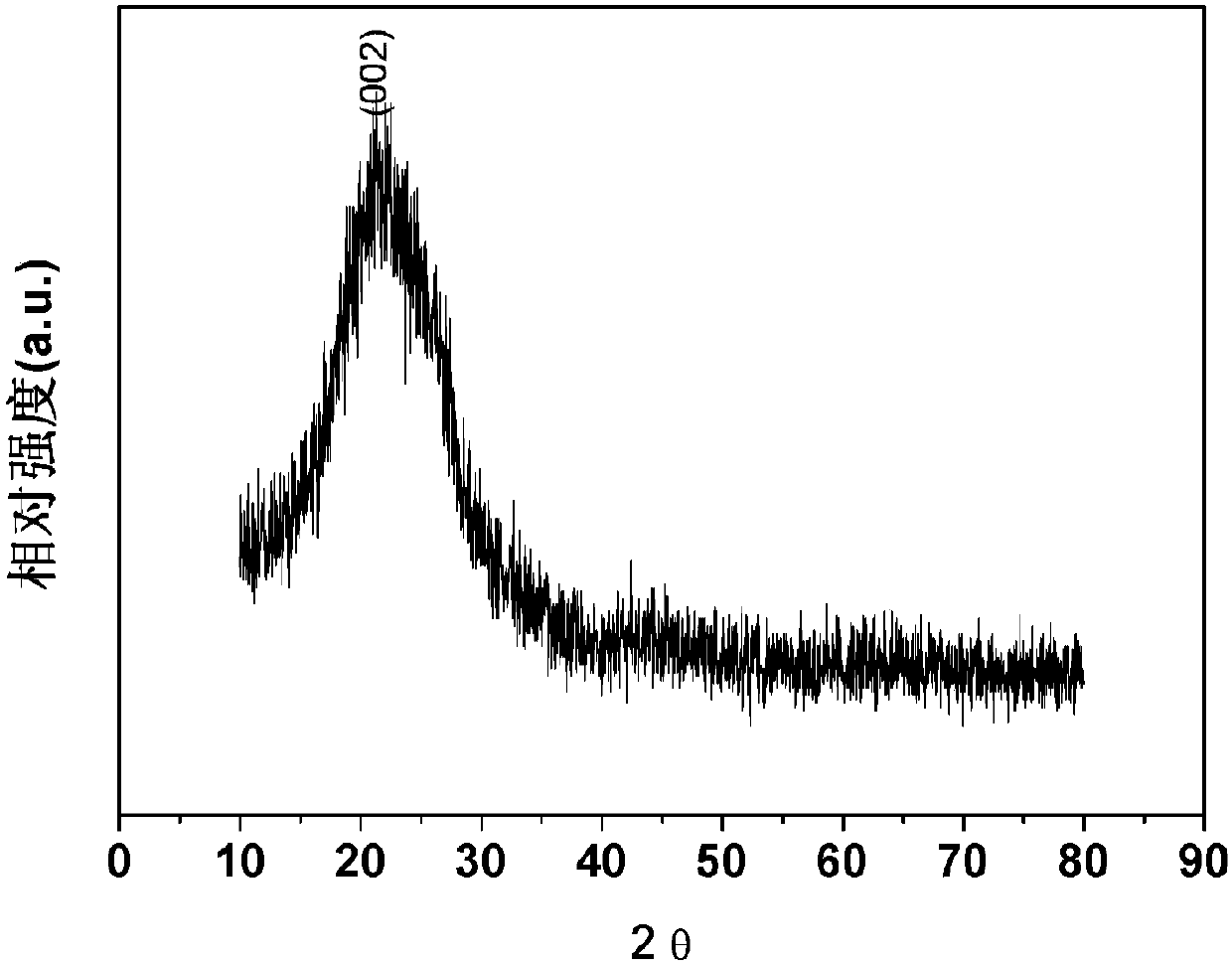

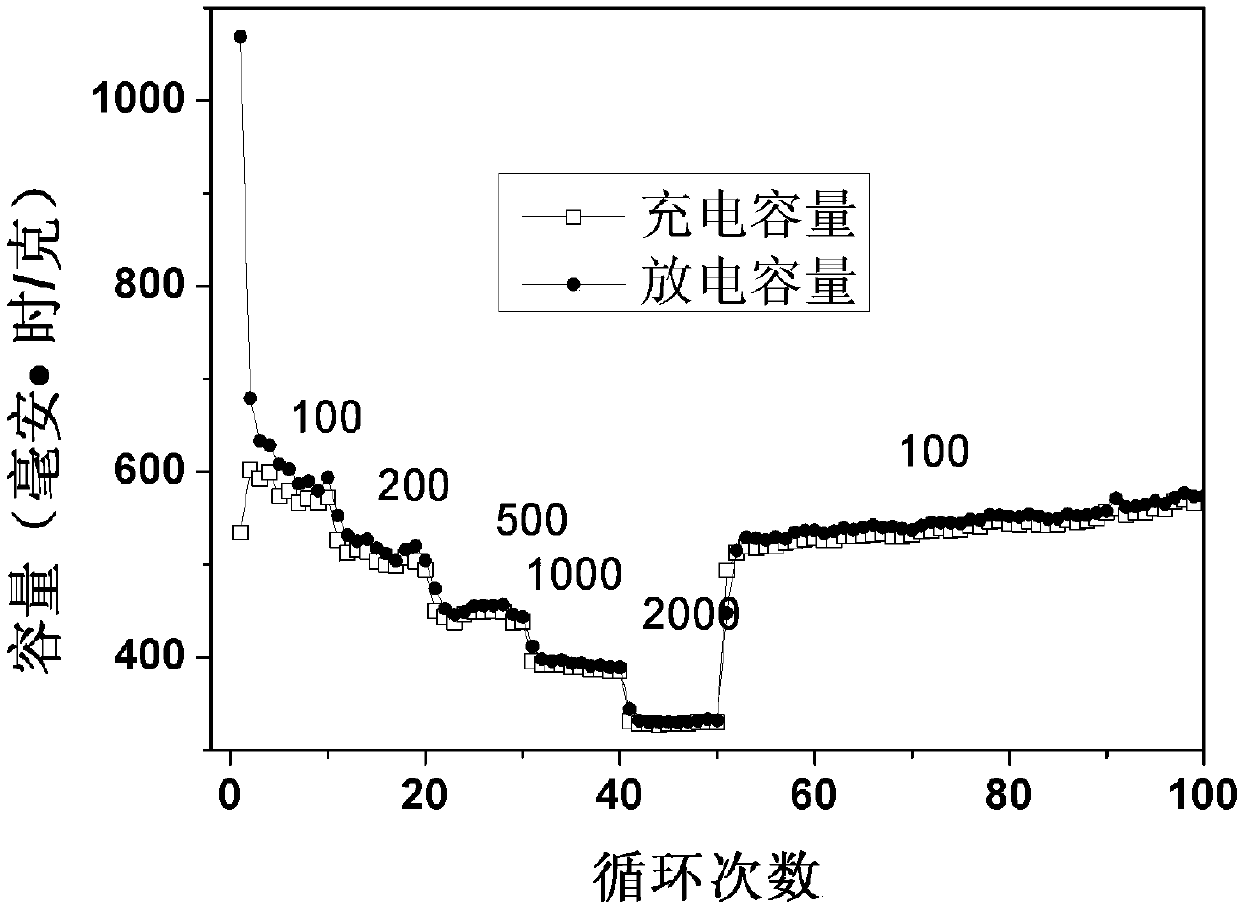

Preparation method of nitrogen-doped porous carbon and application of nitrogen-doped porous carbon in lithium-ion batteries

A nitrogen-doped porous carbon, lithium-ion battery technology, applied in the preparation/purification of carbon, battery electrodes, secondary batteries, etc. Problems such as limited atomic content, to achieve excellent cycle stability, easy large-scale industrial production, and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing nitrogen-doped porous carbon, specifically comprising the following steps:

[0027] 1) Dissolving the nitrogen source in a solvent to prepare a transparent solution, and adding an appropriate amount of carbon source to the above solution to form a fluffy snowflake-like substance, and drying the above-mentioned snowflake-like substance in a freeze dryer for 1-10 hours;

[0028] 2) The mixed substance obtained after drying in step 1) is heated to 300-1200°C for 1-8h at a rate of 1-8°C / min under an argon atmosphere in a vacuum tube furnace, and then separated and purified to obtain the target product.

[0029] As an improvement, the nitrogen source is a water-soluble ammonium salt selected from melamine (C 3 h 6 N 6 ), ammonium chloride (NH 4 Cl), urea (CO(NH 2 ) 2 ), ammonium bisulfate (NH 4 HSO 4 ) or ammonium nitrate (NH 4 NO 3 ) in any one.

[0030] As an improvement, the solvent of the nitrogen source is selected from deionized water ...

Embodiment 1

[0038] A method for preparing nitrogen-doped porous carbon, specifically comprising the following steps:

[0039] 1) Take 0.3g NH 4 Cl was put into a beaker and 1ml of deionized water was added, and a transparent solution was prepared by ultrasonic oscillation. Gradually, 1.2g of highly water-soluble sodium polyacrylate was added to the above transparent solution, and ultrasonic stirring was performed while adding; finally, deionized water was slowly added to form a relatively clear solution. Fluffy white snowflake-like substance, the above-mentioned substance was transferred to a freeze dryer and dried for 10 hours to obtain a white dry powder;

[0040] 2) After the drying is completed, take an appropriate amount of powder and put it in a crucible, and heat it up to 850°C at a rate of 3°C / min under an argon atmosphere in a vacuum tube furnace for 5 hours. The resulting black product is washed repeatedly with deionized water, and washed with Buchner funnel suction filtration,...

Embodiment 2

[0050] A method for preparing nitrogen-doped porous carbon, specifically comprising the following steps:

[0051] 1) Take 0.3g NH 4 Put Cl into a beaker and add 1ml of deionized water for ultrasonic oscillation to prepare a transparent solution. Gradually add 1.2g of highly water-soluble potassium polyacrylate to the above transparent solution, and stir ultrasonically while adding; finally add deionized water slowly until a fluffy solution is formed. The white snowflake-like substance, the above-mentioned substance is transferred to a freeze dryer and dried for 10 hours to obtain a white dry powder;

[0052] 2) After the drying is completed, put an appropriate amount of powder in a crucible and heat it up to 650°C at a rate of 3°C / min in an argon atmosphere in a vacuum tube furnace for 5 hours. The resulting black product is washed repeatedly with deionized water and washed with Buchner funnel suction filtration, drying to obtain a black powder product.

[0053] The obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com