Nanometer Al contained Ni and the preparing method

A technology of nano-nickel powder and nano-nickel, applied in the direction of coating, etc., can solve the problems of unfavorable combustion, incomplete combustion, low combustion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of nano-nickel clad aluminum powder is carried out according to the following steps:

[0041] (1), 130 grams of nickel sulfate (commercially available, analytically pure, molecular formula NiSO 4 ·6H 2 O) be dissolved in 3 liters of pure water, and add 10 grams of polyvinyl alcohol, stir to make it dissolve, obtain solution I;

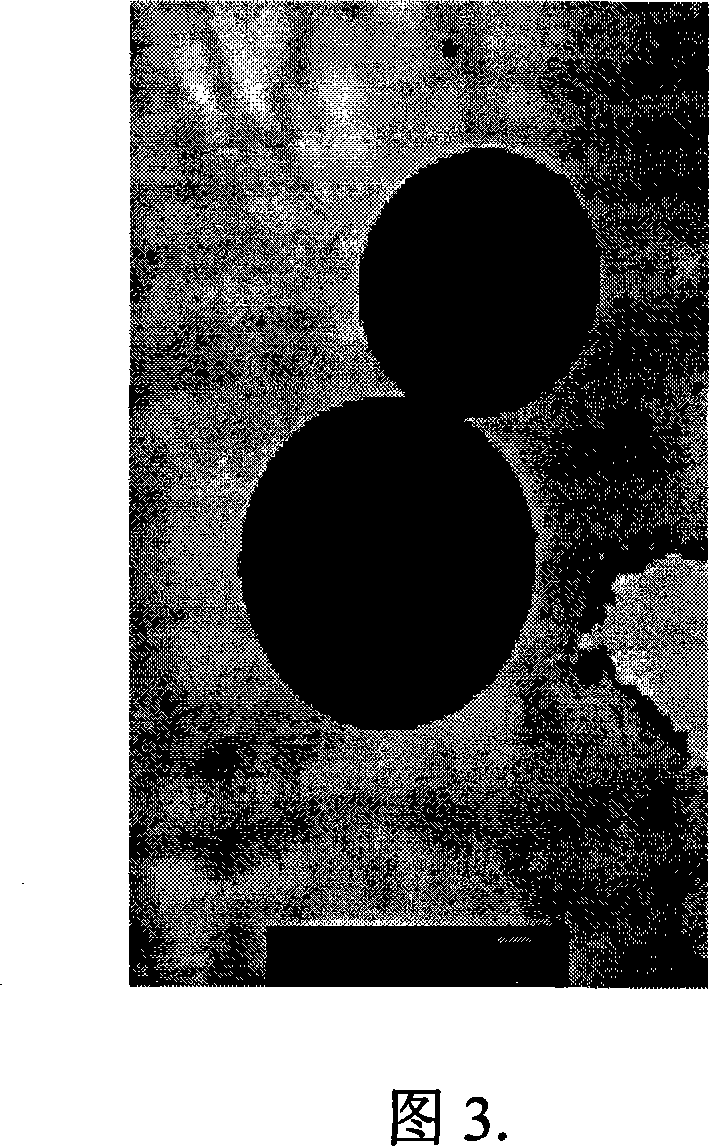

[0042] (2) Soak 500 grams (the brand is FLQT3) of spherical aluminum powder (see Figure 3 for its electron microscope image) into 2 liters of sodium hydroxide aqueous solution with a concentration of 0.02 mol / liter; stir for 10 to 30 minutes to remove the surface of the aluminum powder 200 milliliters of aqueous solution containing 15 grams of potassium borohydride and 5 milliliters of hydrazine hydrate are poured into this container again, stir well, obtain solution II;

[0043] (3), solution I was poured into solution II, and continued to stir for 30 minutes to produce a precipitate;

[0044] (4), stop stirring, leave stands...

Embodiment 2

[0048] The chemical composition of the nano-nickel-clad aluminum powder prepared in Example 1 was analyzed.

[0049] Quantitative analysis was carried out by complexometric titration. Weigh 1 gram of nano-nickel-coated aluminum powder with a nickel content of 3wt% and place it in a 250-ml beaker, add 20 milliliters of 1:1 analytically pure HCl aqueous solution, after the nano-nickel-coated aluminum powder dissolves, add pure water to dilute to 200 milliliters. Take 20 ml of the above solution and adjust the pH value to <6. A small amount of ammonium fluoride was added to the solution as an aluminum ion masking agent. Add a few drops of 3% xylenol orange aqueous solution as indicator. Titrate the nickel in this solution with 0.05M EDTA (ethylenediaminetetraacetic acid) standard solution. The end point of the reaction changed from reddish purple to yellow. The nickel content in the solution can be calculated. The results show that the weight ratio of nickel in the nano-nick...

Embodiment 3

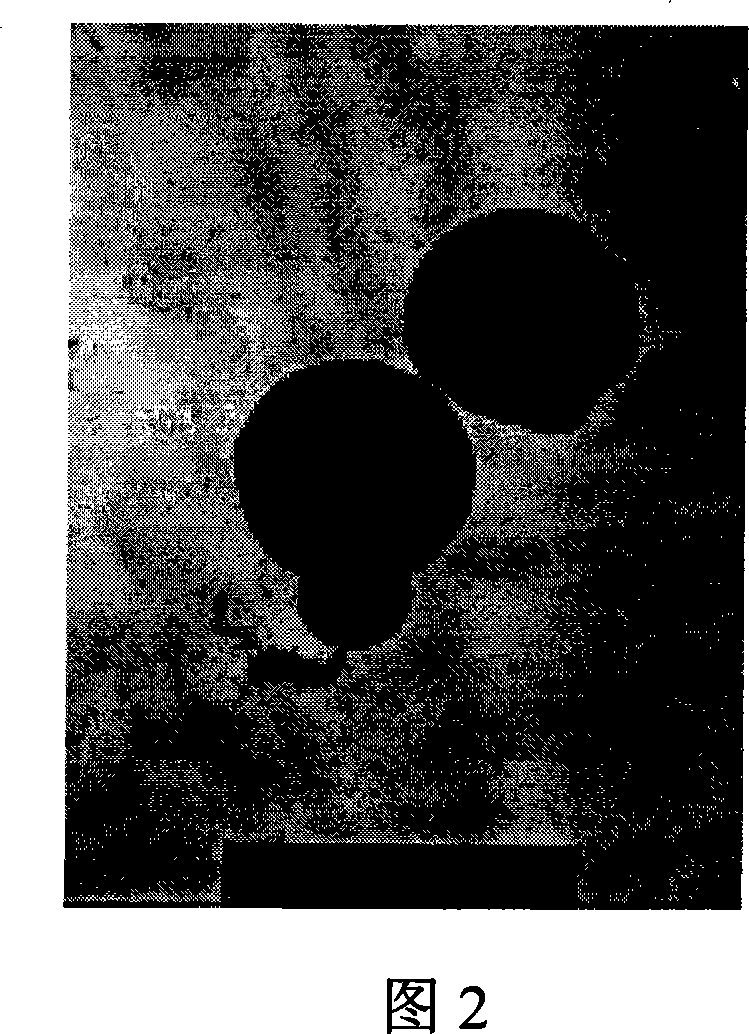

[0051] The nano-nickel-coated aluminum powder prepared in Example 1 was detected by transmission electron microscopy according to the usual method, and the results showed that the thickness of the nano-nickel layer was 120 nanometers (see Figure 2), indicating that a layer of nano-nickel was coated on the surface of the spherical aluminum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com