Graphene and carbon nanotube mixed enhanced metal-matrix composite material and preparation method thereof

A carbon nanotube and composite material technology, which is applied in the field of graphene and carbon nanotube hybrid reinforced metal matrix composite materials and their preparation, can solve the problems of insignificant improvement in thermal conductivity and electrical conductivity, limited volume content and low absolute value, etc. Achieve excellent mechanical and electrical conductivity, easy agglomeration, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

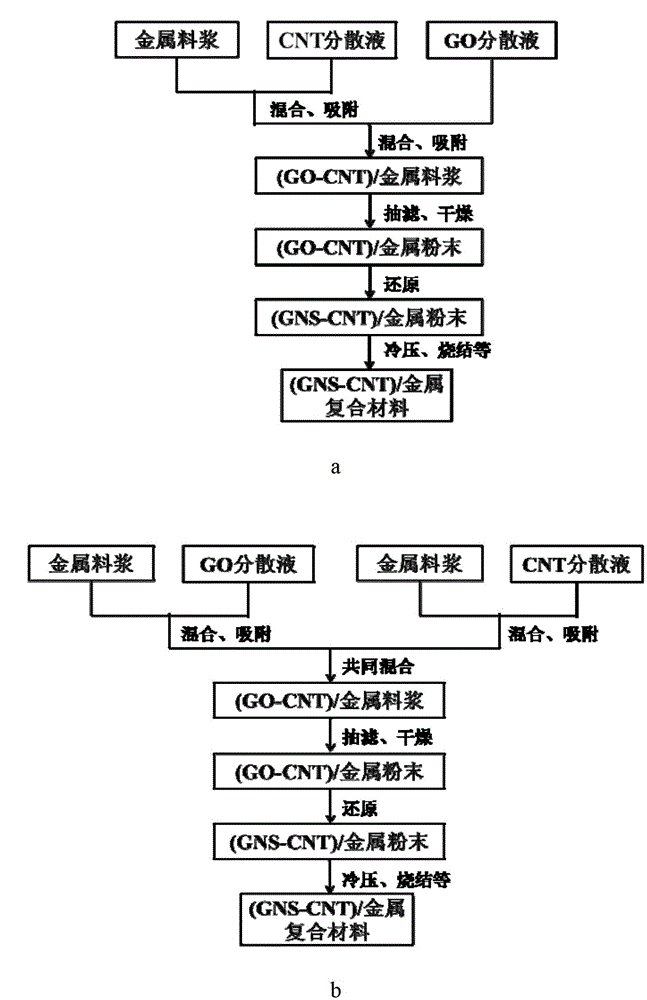

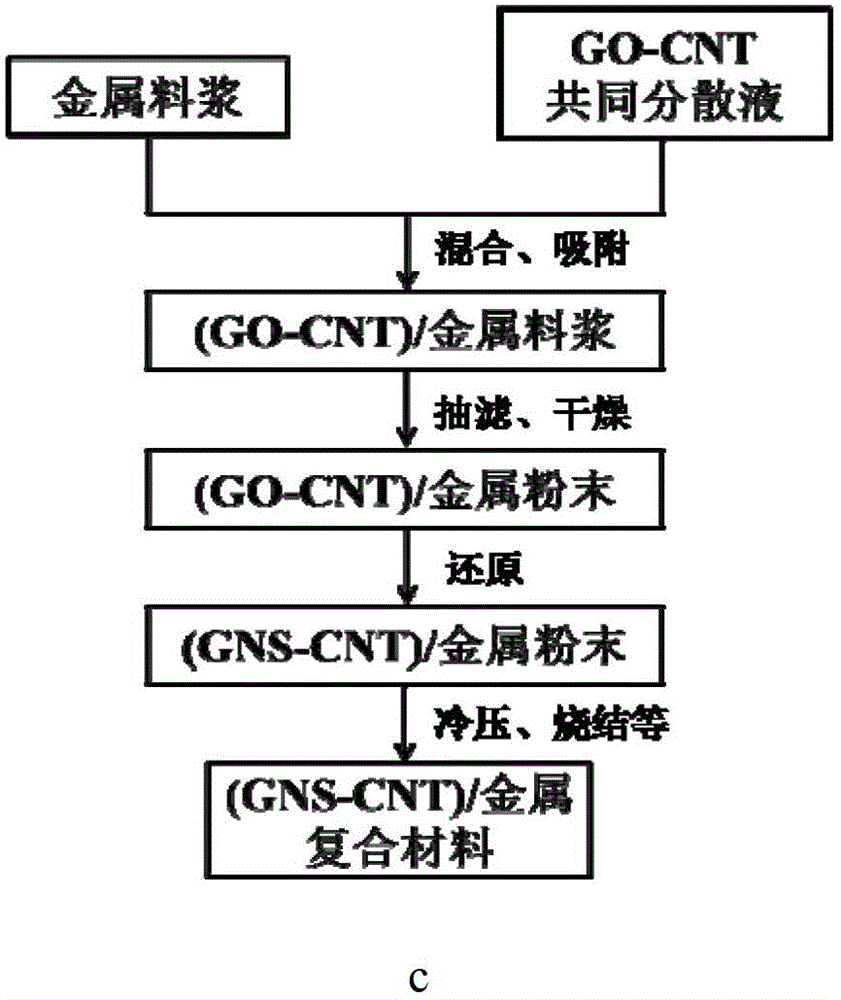

Method used

Image

Examples

Embodiment 1

[0049] Add 40mg of graphite oxide powder and 200mg of carbon nanotubes into 200mL of deionized water at the same time, and disperse them uniformly by ultrasonic dispersion for 2 hours to obtain a mixed solution of 0.2mg / mL graphene oxide and 1.0mg / mL carbon nanotubes. For TEM images see image 3 ;

[0050] Under the condition of heating in a constant temperature water bath at 98°C, dissolve polyvinyl alcohol in deionized water, stir it until it is completely dissolved, add deionized water after cooling to room temperature to adjust the concentration of polyvinyl alcohol, and obtain a 3wt.% polyvinyl alcohol aqueous solution;

[0051] Take 100g of spherical aluminum powder with a thickness of 45 μm and 500 mL of absolute ethanol, and add them together to a stirring ball mill for wet ball milling for 2 hours to obtain flake aluminum powder with a thickness of 4 μm. Due to the active chemical properties of aluminum metal, it may react chemically with carbon substances, so a cert...

Embodiment 2

[0073] 100mg of graphite oxide powder and 600mg of carbon nanotubes were added to 200mL of absolute ethanol and a small amount of sodium lauryl sulfate, and ultrasonically dispersed for 2 hours to make them uniformly dispersed to obtain 0.5mg / mL graphene oxide and 3.0mg / mL mL of carbon nanotube solution;

[0074] Dissolving polyvinylpyrrolidone in ethanol and adding a small amount of hydrazine hydrate to it, mechanically stirring until completely dissolved, cooling to room temperature, adding ethanol to adjust the concentration of polyvinylpyrrolidone to obtain a 5wt.% polyvinylpyrrolidone ethanol solution;

[0075] Take 200g of copper powder and 200mL of pure water, and add them together to a planetary ball mill for wet grinding to obtain a slurry of flaky copper powder with a thickness of 500nm, and then carry out suction filtration and drying to obtain a copper powder with a thickness of 1 μm;

[0076] Take 100g of copper powder, and add it to 1L of 5wt.% polyvinylpyrrolido...

Embodiment 3

[0080] 200mg of graphite oxide powder and 1000mg of carbon nanotubes were added to 200mL of deionized water respectively, and a small amount of surfactant chitosan was added, and ultrasonically dispersed for 2 hours to make them uniformly dispersed to obtain a 1.0mg / mL graphene oxide solution and 5.0 mg / mL carbon nanotube solution;

[0081] Under the condition of heating in a constant temperature water bath at 98°C, dissolve polyvinyl alcohol in deionized water, add a small amount of reducing agent ethylenediamine, stir mechanically until it is completely dissolved, and add deionized water after cooling to room temperature to adjust the concentration of polyvinyl alcohol to obtain 0.5wt.% polyvinyl alcohol aqueous solution;

[0082] Take 200g of aluminum alloy 6061 powder and 500mL of absolute ethanol, and add them together to a stirring ball mill for wet grinding to obtain flaky 6061 powder with a thickness of 500nm, which is the required flaky 6061 powder;

[0083] Take 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com