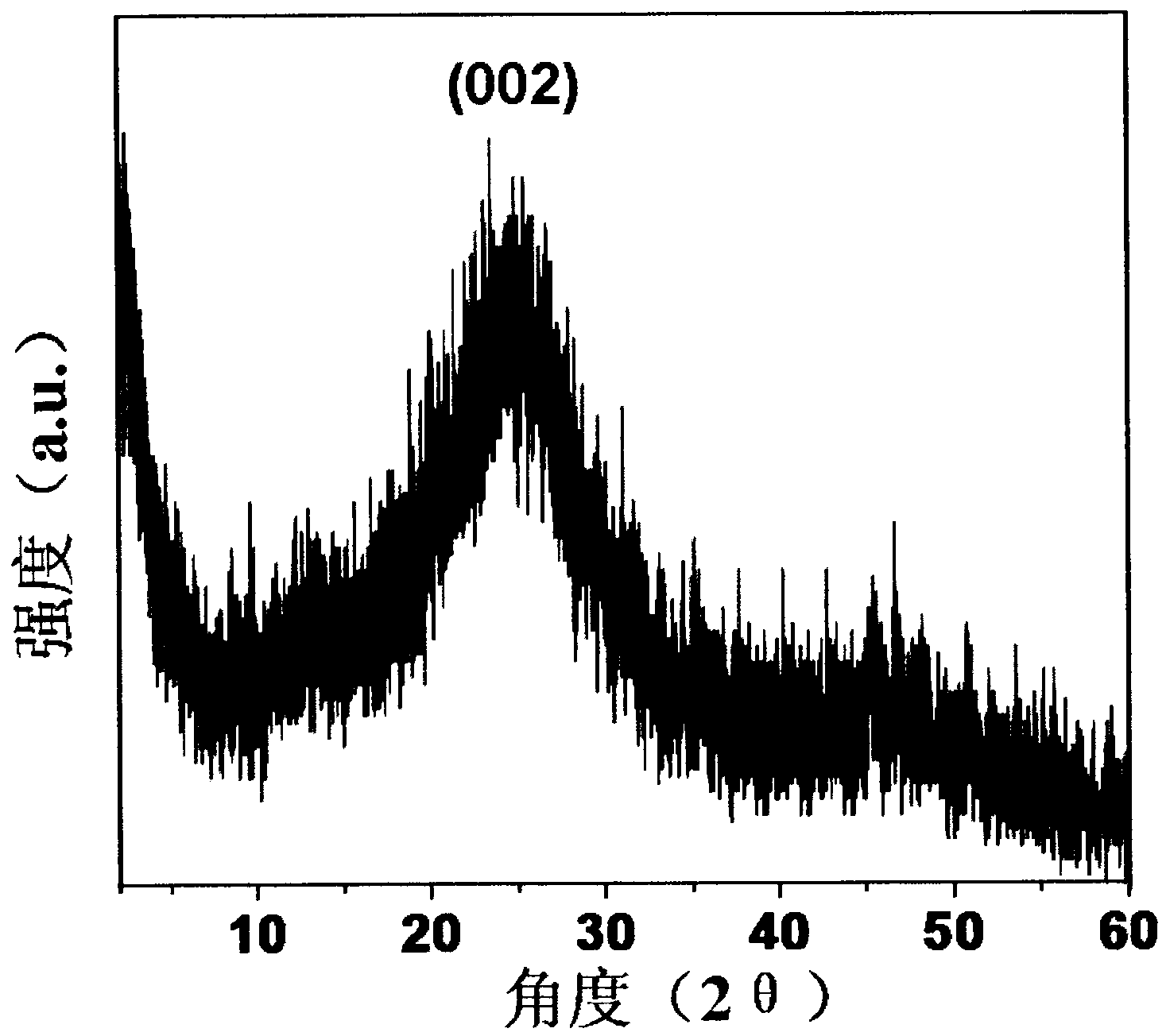

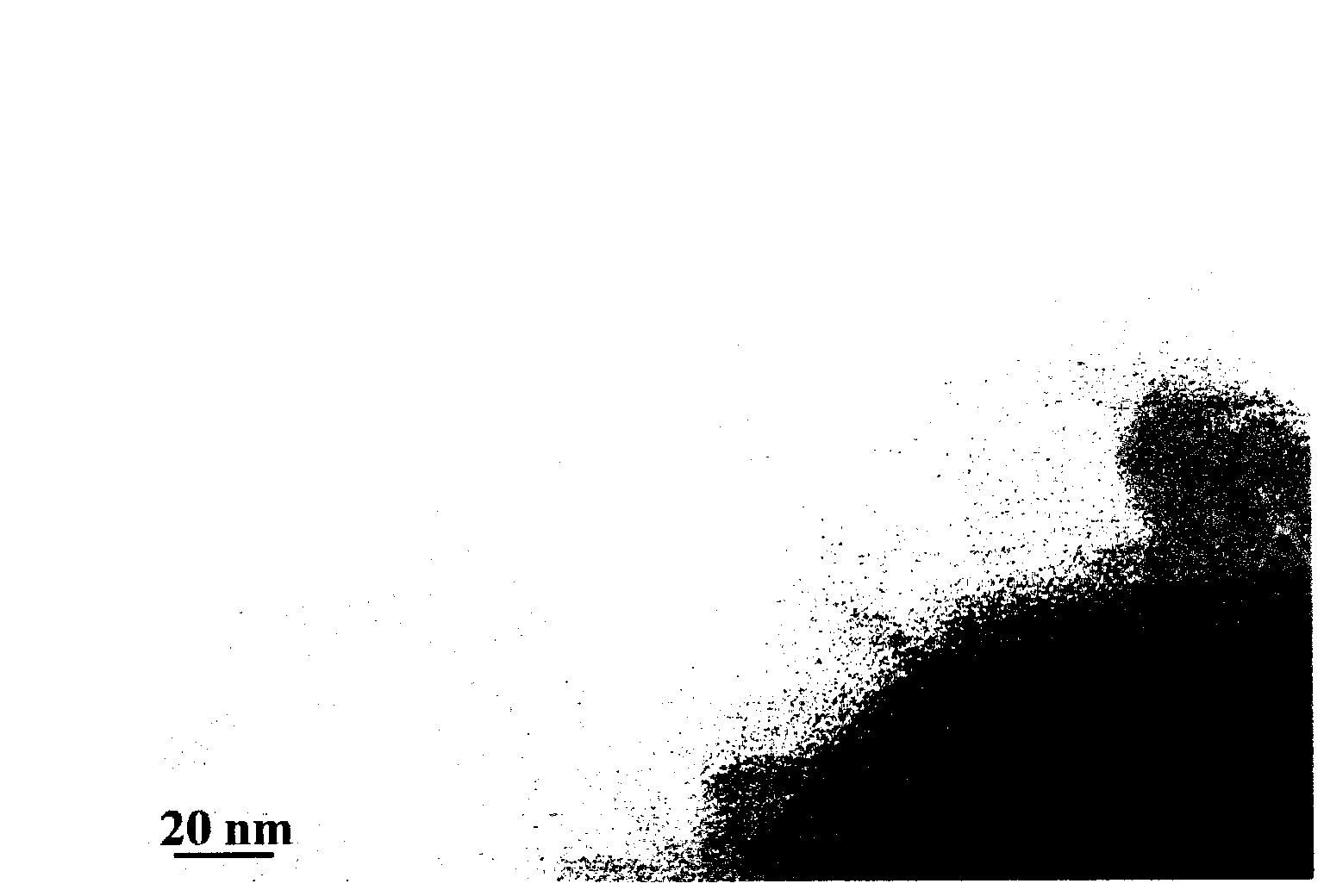

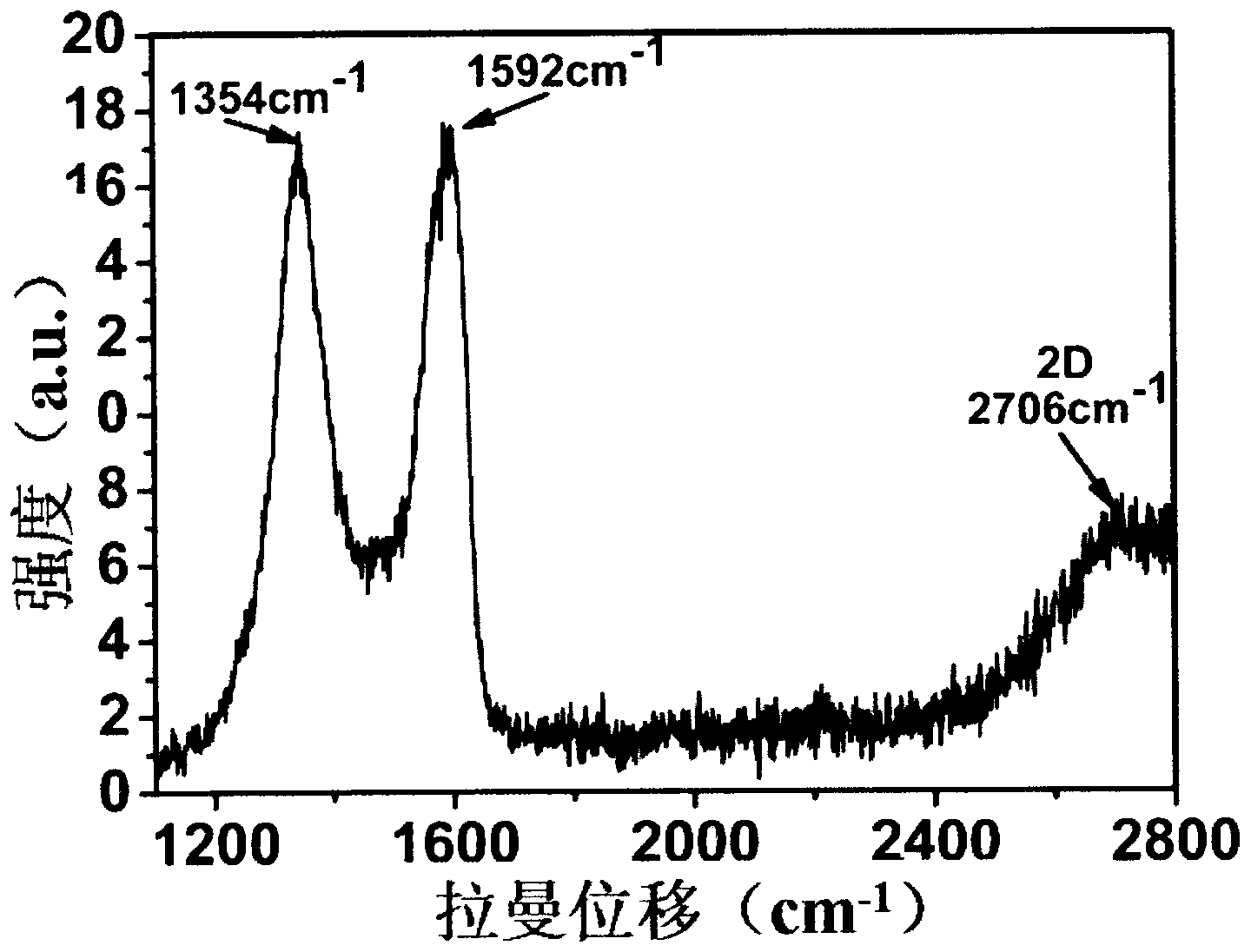

Preparation method of graphene

A technology of graphene and graphite powder, which is applied in the field of materials, can solve the problems of many layers of graphene, serious environmental pollution, and low yield, and achieve the effects of simple preparation method, low production cost, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 200g of deionized water and 20g of N-vinyl-2-pyrrolidone (the mass ratio of N-vinyl-2-pyrrolidone and water is 1:10) into the reactor, and stir at room temperature for 0.5h, Mix the solution thoroughly. Add 20 g of sodium hydroxide (the mass ratio of sodium hydroxide and water is 1:10), and continue stirring for 0.5 h to obtain a mixed solution. Then add 2g of graphite powder, ultrasonic treatment (500W, 50Hz) for 1h to obtain a suspension containing graphite powder, centrifuge at 600rpm to remove impurities, and then centrifuge at a speed of 20000rpm to collect the centrifuged product.

[0030] (2) The above-mentioned product was frozen at -30°C for 8 hours, then placed in a closed reactor, puffed at 200°C, the puffed powder was collected, and treated with a high-speed jet crushing device for 1 hour.

[0031] (3) Add the above product into a mixed solution of ethanol and water (mass ratio 1:10), ultrasonically disperse (500W, 50Hz) for 0.5h, wash with water, a...

Embodiment 2

[0039] (1) Add 200g of deionized water and 20g of N-vinyl-2-pyrrolidone (the mass ratio of N-vinyl-2-pyrrolidone and water is 1:10) into the reactor, and stir at room temperature for 0.5h, Mix the solution thoroughly. Add 25 g of potassium hydroxide (the mass ratio of potassium hydroxide to water is 1:8), and continue stirring for 0.5 h to obtain a mixed solution. Then add 3g of graphite powder, ultrasonic treatment (1000W, 50Hz) for 1h to obtain a suspension containing graphite powder, centrifuge at 600rpm to remove impurities, and then centrifuge at a speed of 20000rpm to collect the centrifuged product.

[0040] (2) The above-mentioned product was frozen at -30°C for 8 hours, then placed in a closed reactor, puffed at 150°C, the puffed powder was collected, and treated with a high-speed jet mill for 1 hour.

[0041] (3) Add the above product into a mixed solution of ethanol and water (mass ratio 1:10), ultrasonically disperse (500W, 50Hz) for 1h, wash with water, and spray...

Embodiment 3

[0044](1) Add 200g of deionized water and 10g of N-methyl-2-pyrrolidone (the mass ratio of N-methyl-2-pyrrolidone and water is 1:20) into the reactor, and stir at room temperature for 0.5h, Mix the solution thoroughly. Add 20 g of potassium hydroxide (the mass ratio of potassium hydroxide to water is 1:10), and continue stirring for 0.5 h to obtain a mixed solution. Then add 2g of graphite powder, ultrasonic treatment (500W, 50Hz) for 0.5h to obtain a suspension containing graphite powder, centrifuge at 600rpm to remove impurities, then centrifuge at a speed of 20000rpm to collect the centrifuged product.

[0045] (2) Freeze the above product at -50°C for 10 hours, then place it in a closed reactor, puff it at 200°C, collect the puffed powder, and process it with a high-speed airflow mill for 2 hours.

[0046] (3) Add the above product into a mixed solution of ethanol and water (mass ratio 1:10), ultrasonically disperse (500W, 50Hz) for 0.5h, wash with water, and spray dry. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com