Preparation method of fewer-layer graphene

A few-layer graphene and graphite technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., to achieve the effects of high yield, simple operation, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 2.08g of graphite powder to 300ml of aqueous solution containing 0.8g of tetraethylammonium tetrafluoroborate, 0.15g of sodium hydroxide and 50mg of thionine. After stirring evenly, place the suspension in an 855W ultrasonic cell disruptor Ultrasonic 6h. After the sonication, vacuum filter with a nylon microporous membrane, and wash the filter residue 3 times with 100ml of deionized water and 100ml of absolute ethanol, respectively, to remove residual substances. Then the filter residue was transferred to a watch glass, and vacuum-dried at 60° C. for 2 h to obtain dry graphite powder. Afterwards, place the dried graphite powder in a 900W microwave oven for 5 minutes of irradiation, add it to 700ml of N-methylpyrrolidone, and ultrasonicate it in a 250W ultrasonic cleaner for 12 hours. Then, the ultrasonically treated solution was transferred to a centrifuge tube, centrifuged at a speed of 5000 rpm for 10 minutes, and the upper layer solution was taken out to obtain ...

Embodiment 2

[0047] In this example, the graphite powder is first subjected to electrochemical pretreatment, and then the graphene is prepared in the same manner as in Example 1. The specific process is as follows:

[0048] Take 12g of graphite powder and press it into a rod shape, immerse in a mixed solution of 20ml dimethyl sulfoxide and 60ml water containing 0.8gNaCl as the cathode, and another graphite rod as the anode. Put a voltage of 5V on the two electrodes, and after 18 hours of reaction, the electrolyte is vacuum-filtered with a microporous membrane, and the graphite powder obtained by washing and filtering with 100ml of deionized water and 100ml of ethanol is collected for 3 times, and then the graphite powder is collected. Dry at 60°C for 2h.

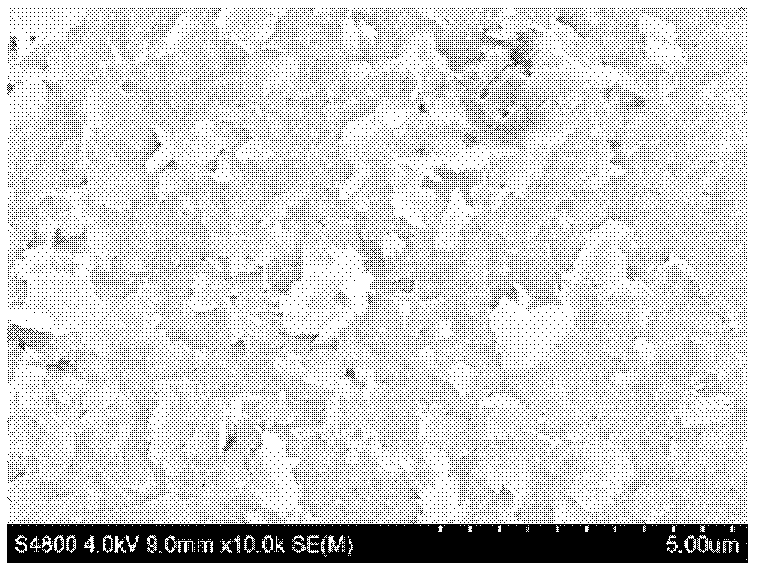

[0049] The graphite powder prepared above was observed with a scanning electron microscope, and the results are shown in Figure 1. From Figure 1, it can be seen that the edges of the graphite particles have been peeled off, and the inte...

Embodiment 3

[0054] This example and Example 1 adopt basically the same method to prepare graphene, the difference is that 0.8g tetraethylammonium tetrafluoroborate and 0.15g sodium hydroxide are replaced by 0.54g tetraethylammonium hydroxide. Equally, can obtain the graphene dispersion liquid similar to that shown in Fig. 1 (a), its graphene yield is substantially identical with embodiment 1. Like Example 1, the dispersion was stable. Similar to Example 1, the graphene prepared by using the dispersion liquid has the advantages of few layers, few defects, few oxygen-containing groups, and high electrical conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com