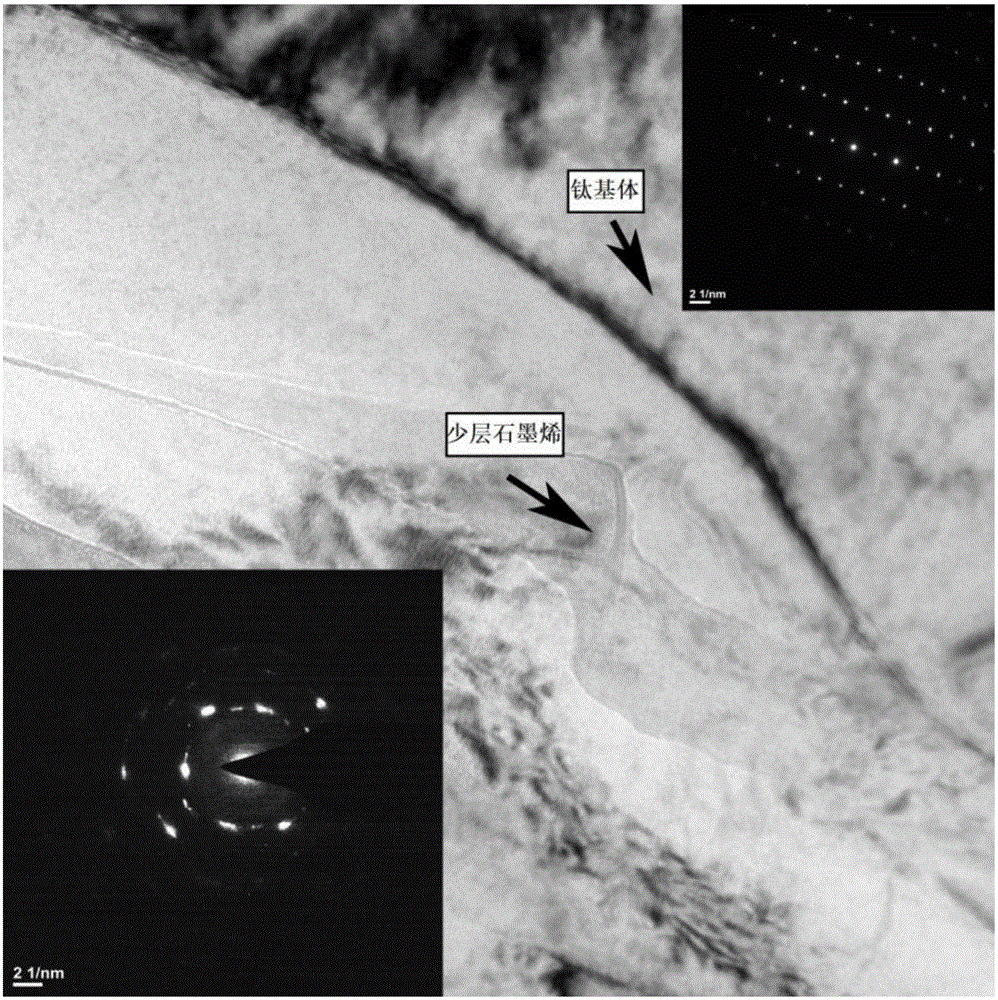

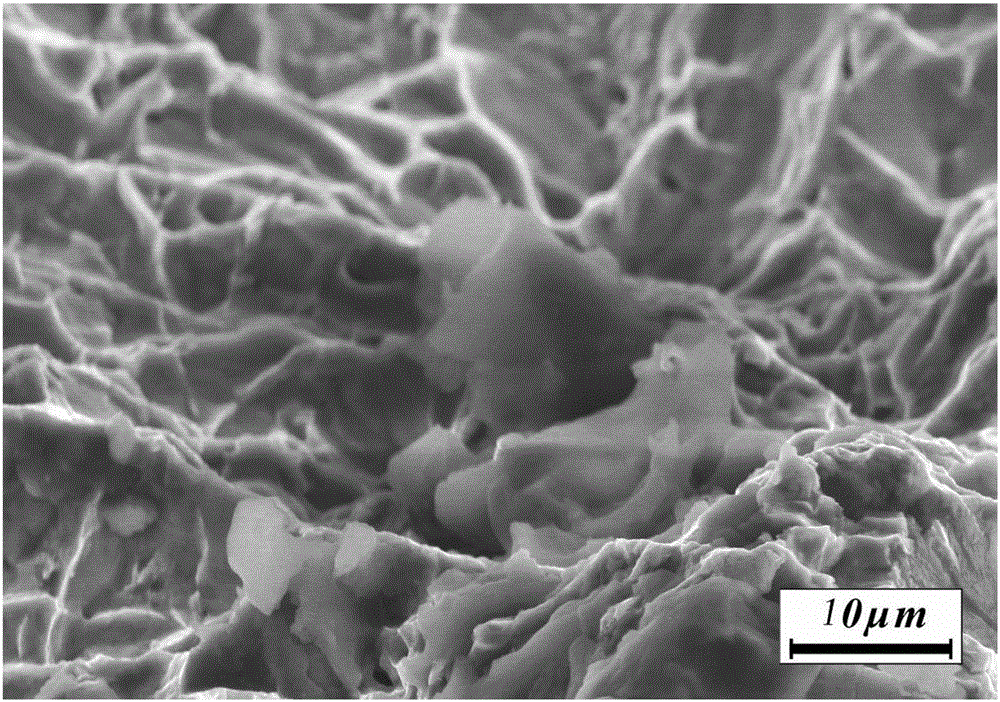

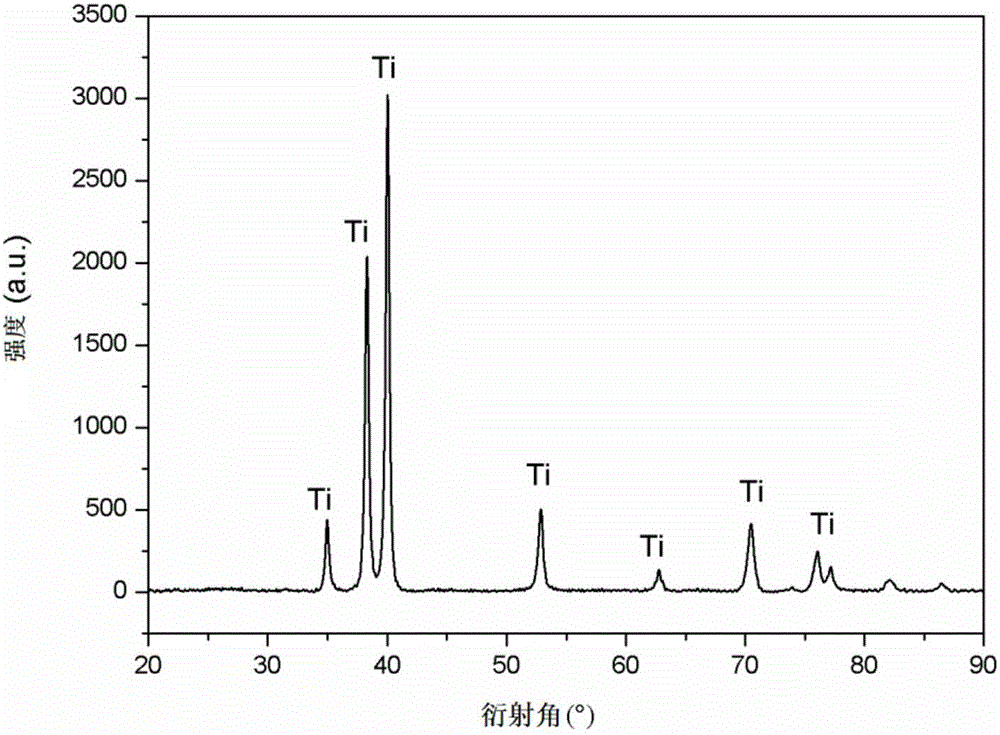

Low-content few-layer graphene intensified titanium-based composite material and preparation method

A titanium-based composite material and few-layer graphene technology, applied in the field of metal-based composite materials, can solve the problems such as the performance of TiMCs needs to be improved, and achieve the effects of less impurity content, simple process and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of pure titanium: mix titanium powder with absolute ethanol and ultrasonically disperse for 20 to 30 minutes; then transfer to a ball mill jar and add ball milling beads, wherein the mass ratio of ball milling beads to titanium powder is 5 to 6:1, Ball mill at 300-350r / min for 2.5-3 hours; then remove the absolute ethanol in the slurry after ball milling to obtain powder; dry the obtained powder in a vacuum oven at 90-100°C for 8-10 hours to obtain the dried Powder; put the dried powder into a steel mold, and put graphite paper inside the mold, then apply a pressure of 250-300MPa to the steel mold, and then heat it to 550-600℃ at a heating rate of 100-150℃ / min, and keep it warm for 9 Naturally cool after ~10 minutes, the product in the steel mold is a rough billet; heat the rough billet to 450-950°C, keep it warm for 9-10 minutes, and immediately roll it, the rolling deformation is 50-60%, and the rolling is completed After air cooling, pure titanium was obt...

Embodiment 1

[0037] A low-content few-layer graphene-reinforced titanium-based composite material, based on the mass of the composite material as 100%, its composition and the mass fraction of each component: few-layer graphene powder 0.400% and titanium powder 99.600%

[0038] The preparation steps of the low-content few-layer graphene-reinforced titanium-based composite material described in this implementation are as follows:

[0039]Mix 0.12g of few-layer graphene powder and 200mL of absolute ethanol and ultrasonically disperse for 30min, then add 30g of titanium powder under stirring to obtain a mixed slurry; transfer the obtained mixed slurry to a ball mill jar, add 180g of zirconia ceramic Ball mill the beads, mill at 300r / min for 2.5h, use a rotary evaporator at 65r / min and 75°C to remove the absolute ethanol in the slurry after ball milling to obtain a powder; put the obtained powder in a vacuum oven at 90°C Dry for 10 hours to obtain dried powder; put the obtained dried powder in...

Embodiment 2

[0043] A low-content few-layer graphene-reinforced titanium-based composite material, based on the mass of the composite material as 100%, its composition and the mass fraction of each component: few-layer graphene powder 0.050% and titanium powder 99.950% .

[0044] The preparation steps of the low-content few-layer graphene-reinforced titanium-based composite material described in this implementation are as follows:

[0045] Mix 0.015g of few-layer graphene powder and 200mL of absolute ethanol and ultrasonically disperse for 20min, then add 30g of titanium powder under stirring to obtain a mixed slurry; transfer the obtained mixed slurry to a ball mill jar, add 150g of zirconia ceramic Ball mill the beads, mill at 350r / min for 2.5h, use a rotary evaporator at 65r / min and 75°C to remove the absolute ethanol in the slurry after ball milling to obtain a powder; put the obtained powder in a vacuum oven at 100°C Dry for 12 hours to obtain dried powder; put the obtained dried pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com