High-concentration few-layer graphene composite material, component of lithium battery electrode and preparation

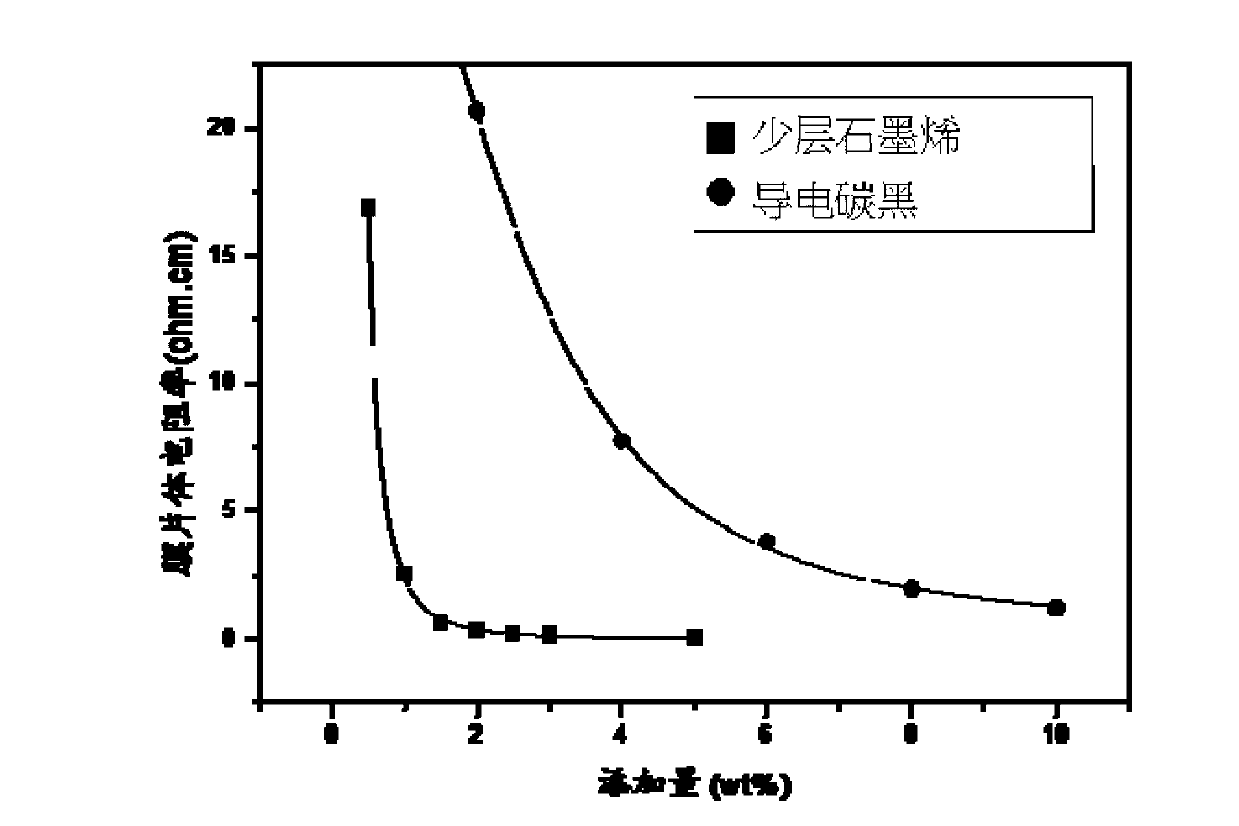

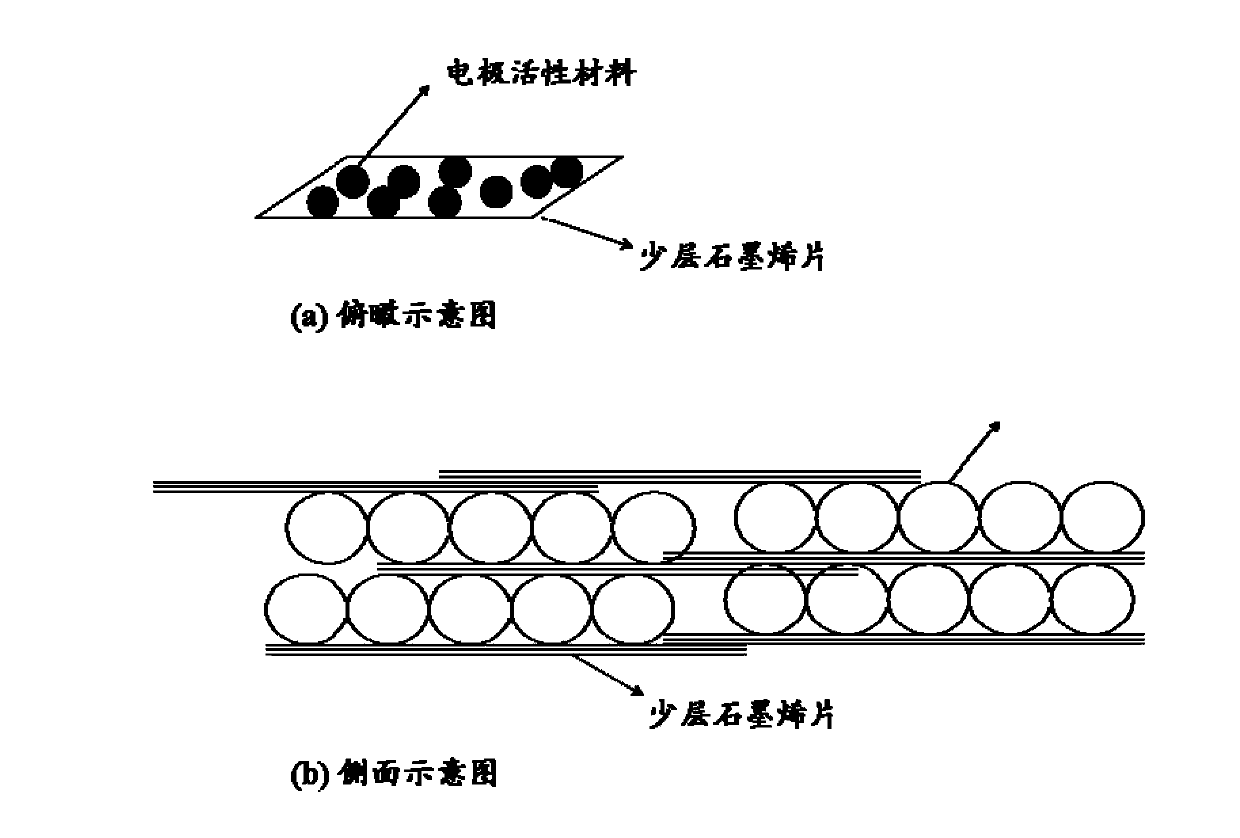

A technology of few-layer graphene and composite materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of incomplete cleavage of graphite sheets, easy folding back, and decreased conductivity, so as to avoid the decline of electrical conductivity, Good dispersion and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

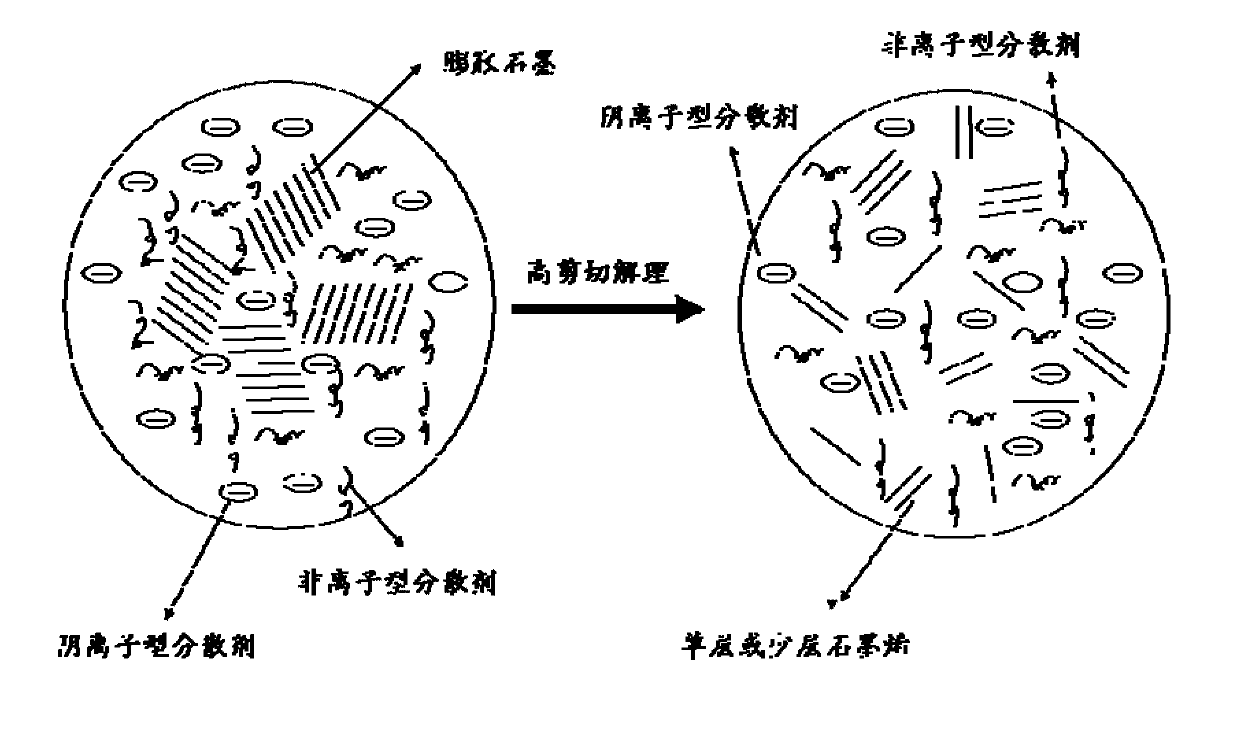

Method used

Image

Examples

Embodiment 1

[0038] The composition and preparation of high-concentration few-layer graphene composite material and lithium battery electrode are carried out according to the following steps:

[0039] (1) Add 10g of natural graphite (100 mesh) into a mixed solution of 170g of concentrated sulfuric acid and fuming nitric acid, add 20g of potassium chlorate at a temperature of 5°C, and keep stirring for 96 hours. Filter the mixed solution with filter paper and filter it with 5wt % hydrochloric acid to wash the residue until no sulfate is detected, then wash the residue with deionized water until the pH is 6, and dry the residue in an oven at 70°C for 48 hours to obtain expandable graphite. Put the expandable graphite into a muffle furnace filled with argon, set the temperature at 1050°C, and heat for 2 minutes to obtain expanded graphite.

[0040] (2) Add 30g of polyvinyl alcohol (PVA) to 519g of N-methylpyrrolidone (nMP), stir for 30 minutes until completely dissolved; then add 5g of sodium d...

Embodiment 2

[0046] (1) Add 10g of natural graphite (100 mesh) into a mixed solution of 170g of concentrated sulfuric acid and fuming nitric acid, add 20g of potassium chlorate at a solution temperature of 4°C, and keep stirring for 96 hours. Filter the mixture with filter paper and use Wash the residue with 5wt% hydrochloric acid until no sulfate is detected, then wash the residue with deionized water until the pH is 7, and dry the residue in an oven at 70°C for 48 hours to obtain expandable graphite. Put the expandable graphite into a muffle furnace filled with argon, set the temperature at 1050°C, and heat for 2 minutes to obtain expanded graphite.

[0047] (2) Add 30g of polyvinyl alcohol (PVA) into 519g of N-methylpyrrolidone (nMP), stir for 30 minutes until completely dissolved; then add 5g of sodium dodecylsulfonate and 0.5g of phenylethyl alcohol oil in sequence Ester, stirred at 50°C for 30 minutes until completely dissolved to obtain a mixed solution.

[0048] (3) Add 100 g of e...

Embodiment 3

[0052] The composition and preparation of high-concentration few-layer graphene composite material and lithium battery electrode are carried out according to the following steps:

[0053] (1) According to the parts by weight, take 1 part of graphite and add it to the mixed solution of 17 parts of concentrated sulfuric acid and fuming nitric acid, add 2 parts of potassium permanganate at the temperature of the solution at 8°C, and keep stirring for 50 hours. The mixture was filtered with filter paper and the residue was washed with 8wt% hydrochloric acid until no sulfate was detected, then the residue was washed with deionized water until the pH was 6.5, and the residue was dried at 90°C to obtain expandable graphite. The expanded graphite is put into a high-temperature furnace with helium gas, the temperature is set at 800°C, and the heating time is 6 minutes to obtain expanded graphite;

[0054] (2) According to the parts by weight, add 6 parts of polyurethane to 104 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com