Anodic oxidation device and piston anodic oxidation processing process

An anodizing and processing technology, applied in anodizing, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of inability to quickly dissipate heat, affect product quality, and long oxidation time, prevent overburning, improve Oxidation efficiency, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

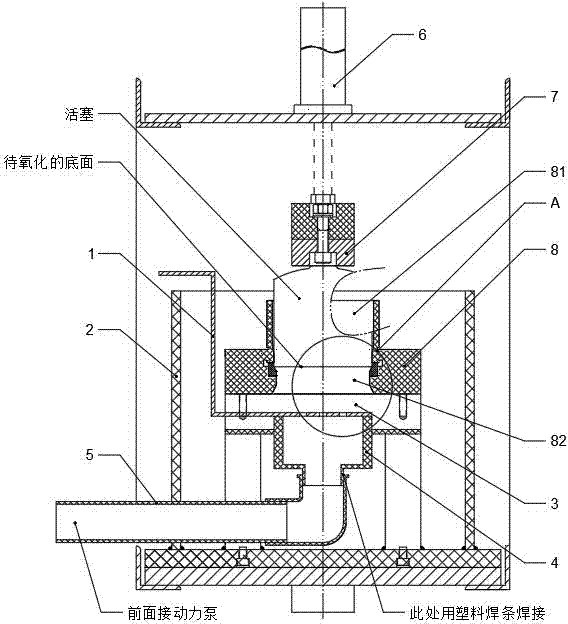

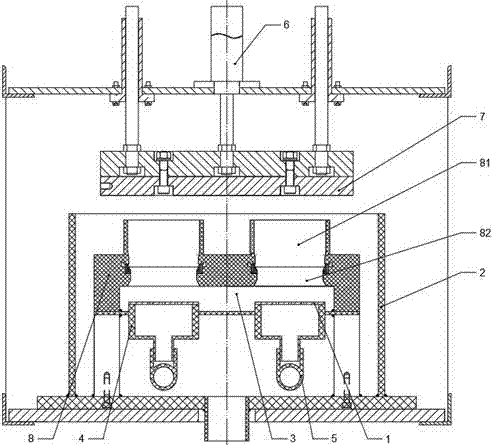

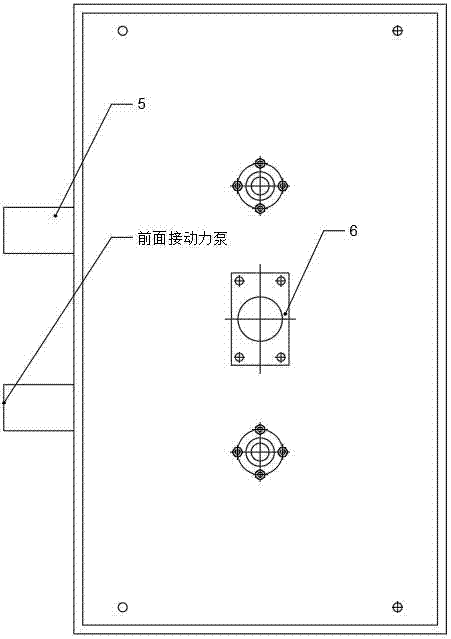

[0034] Example 1, see Figure 1-4 , an anodizing device provided in this embodiment includes a power supply, an electrolyte storage chamber, an anode assembly, a cathode plate 1, an oxidation tank 2, and a power pump; the anode assembly can be detachably connected to the parts to be treated; the cathode The plate 1 is at least partially suitable for immersion in the oxidation tank 2; a return channel 3 is formed between the anode assembly and the cathode plate 1; the return channel 3 communicates with the oxidation tank 2; the bottom of the cathode plate 1 is provided with A spray assembly communicating with the return channel 3; the spray assembly is connected to the electrolyte storage chamber through a power pump; the power supply is electrically connected to the anode assembly and the cathode plate 1 respectively. When in use, put the bottom surface of the piston to be oxidized back into the water channel 3, and make the bottom surface of the plug to be oxidized directly a...

Embodiment 2

[0042] Embodiment 2, a piston anodizing process, using the above-mentioned anodizing device, includes the following steps:

[0043] A Put the piston into the workpiece holding hole so that the bottom surface to be oxidized faces down;

[0044] B starts the cylinder so that the conductive plate is in contact with the piston;

[0045] C Start the power supply and power pump, the electrolyte is sprayed out in the vertical direction through the water storage lotus, and contacts the bottom surface of the piston to be oxidized to form a current loop, and the current density is adjusted by the current controller to complete the anodic oxidation process.

[0046] As a further improvement to the above technical solution, in step C, the flow rate of the power pump is 50-150 L / min, and the head is 5-20m.

[0047] As a further improvement to the above technical solution, in step C, the current density is 40-80A / dm².

Embodiment 3

[0048] Embodiment 3, a piston anodizing process, using the above-mentioned anodizing device, includes the following steps:

[0049] A Put the piston into the workpiece holding hole so that the bottom surface to be oxidized faces down;

[0050] B starts the cylinder so that the conductive plate is in contact with the piston;

[0051] C Start the power supply and power pump, the electrolyte is sprayed out in the vertical direction through the water storage lotus, and contacts the bottom surface of the piston to be oxidized to form a current loop, and the current density is adjusted by the current controller to complete the anodic oxidation process. The flow rate of the power pump is 50L / min, and the head is 5m. The current density is 40A / dm².

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com